In short, the primary disadvantages of a plate and frame filter press are its labor-intensive, batch-style operation, the high recurring cost of replacing filter cloths, and its general unsuitability for fully automated, high-throughput processes. These factors often lead to higher long-term operational costs compared to more modern filtration alternatives.

The core issue with a plate and frame filter press isn't a lack of effectiveness, but a lack of efficiency. Its fundamental design as a manual, batch system creates operational bottlenecks and ongoing costs that can be prohibitive for large-scale or continuous operations.

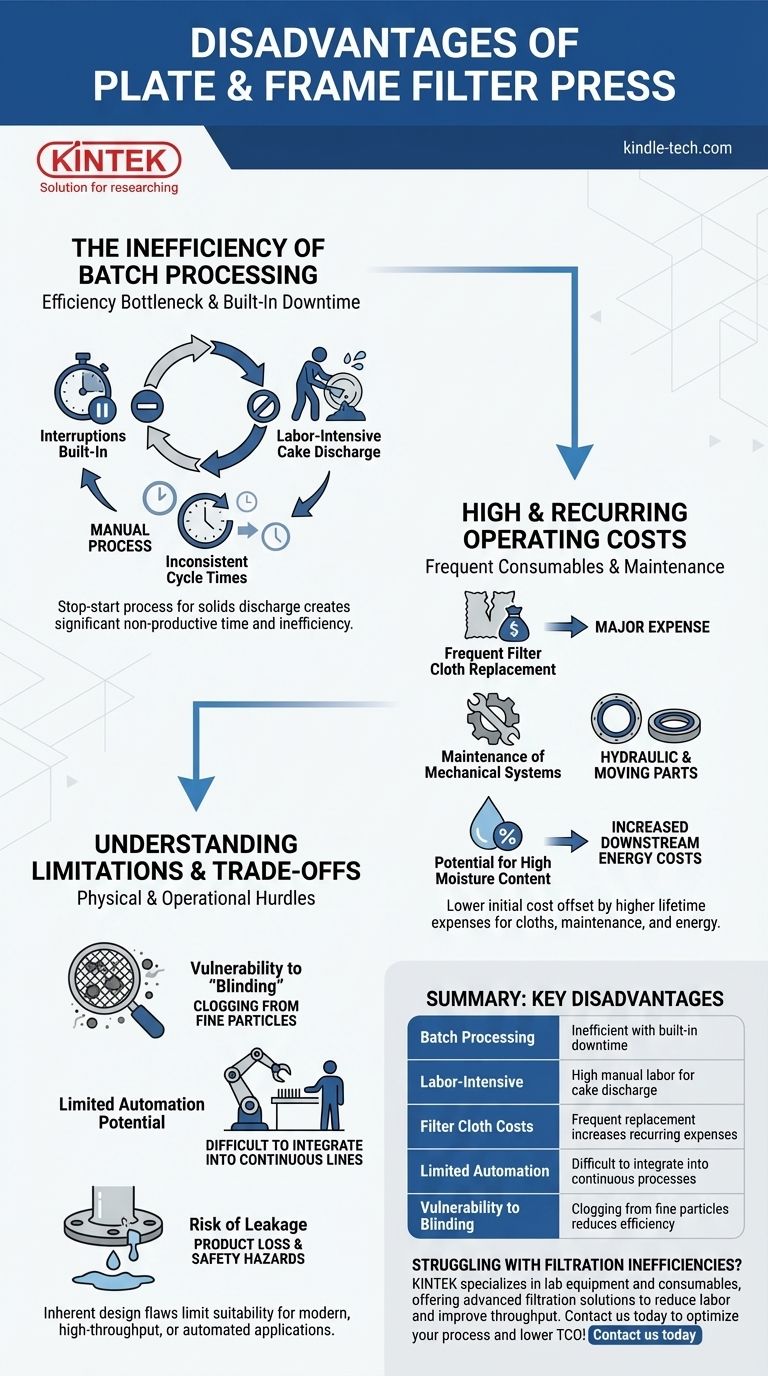

The Inefficiency of Batch Processing

The most significant drawback stems from the fact that a filter press does not operate continuously. The entire process must stop to discharge the collected solids, creating inherent downtime and inefficiency.

Interruptions are Built-In

Filtration is only one part of the cycle. A significant portion of the machine's time is spent on non-productive tasks like opening the press, discharging the cake, and closing it again for the next batch.

Labor-Intensive Cake Discharge

Discharging the filter cake is typically a manual process. An operator must physically separate each plate and scrape the solid cake off the filter cloths. This is time-consuming, physically demanding, and directly increases labor costs.

Inconsistent Cycle Times

The time required to complete a cycle can vary significantly based on the slurry's consistency and solids content. This unpredictability makes it difficult to integrate a filter press smoothly into a larger, continuous production line.

High and Recurring Operating Costs

While the initial capital investment for a plate and frame press can be lower than other technologies, its lifetime operating costs are often much higher due to consumables and maintenance.

Frequent Filter Cloth Replacement

The filter cloth is the primary consumable component. It is subjected to high pressure, abrasive particles, and chemical attack, leading to wear, tearing, and blinding (clogging). Replacing these cloths is a major and recurring operational expense.

Maintenance of Mechanical Systems

The hydraulic system used to clamp the plates, along with any automated plate-shifting mechanisms, requires regular maintenance. Seals, gaskets, and moving parts wear out and must be replaced to ensure proper operation and prevent leaks.

Potential for High Moisture Content

If not operated optimally, a plate and frame press can leave a relatively high moisture content in the filter cake. For applications where the cake must be dried or transported, this excess moisture adds significant downstream energy or disposal costs.

Understanding the Limitations and Trade-offs

Beyond cost and efficiency, the plate and frame design has inherent physical and operational limitations that make it unsuitable for certain applications.

Vulnerability to "Blinding"

The press is particularly susceptible to blinding, where very fine or slimy particles clog the pores of the filter cloth. Once blinded, the cloth's filtration rate plummets, and it often needs to be replaced, further increasing downtime and cost.

Limited Automation Potential

While some features like automatic plate shifters exist, the core process of cake discharge remains difficult to fully automate. This stands in stark contrast to technologies like belt presses or rotary drum filters that are designed for continuous, unattended operation.

Risk of Leakage

Proper operation depends on a perfect seal between each plate and frame. Worn gaskets, warped plates, or improper closing pressure can easily lead to leakage. This not only results in product loss but also creates safety hazards and significant housekeeping challenges.

Making the Right Choice for Your Goal

The disadvantages of a plate and frame filter press are most pronounced when it is misapplied. The key is to match the technology to your specific operational needs.

- If your primary focus is the lowest possible initial capital cost for a low-volume or infrequent process: A manual plate and frame press can be a cost-effective solution where labor and downtime are not critical concerns.

- If your primary focus is high-throughput, continuous operation, and minimal labor: You should strongly consider alternative technologies like a belt filter press, rotary drum filter, or centrifuge.

- If your primary focus is handling slurries with very fine particles that tend to blind filter media: It is crucial to test your material and potentially explore other filtration methods better suited for those solids.

Ultimately, choosing the right filtration equipment requires looking beyond the purchase price to consider the total cost of ownership for your specific application.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Batch Processing | Inefficient with built-in downtime |

| Labor-Intensive | High manual labor for cake discharge |

| Filter Cloth Costs | Frequent replacement increases recurring expenses |

| Limited Automation | Difficult to integrate into continuous processes |

| Vulnerability to Blinding | Clogging from fine particles reduces efficiency |

Struggling with filtration inefficiencies? KINTEK specializes in lab equipment and consumables, offering advanced filtration solutions that reduce labor costs and improve throughput. Our experts can help you select the right technology for your specific needs. Contact us today to optimize your filtration process and lower your total cost of ownership!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation