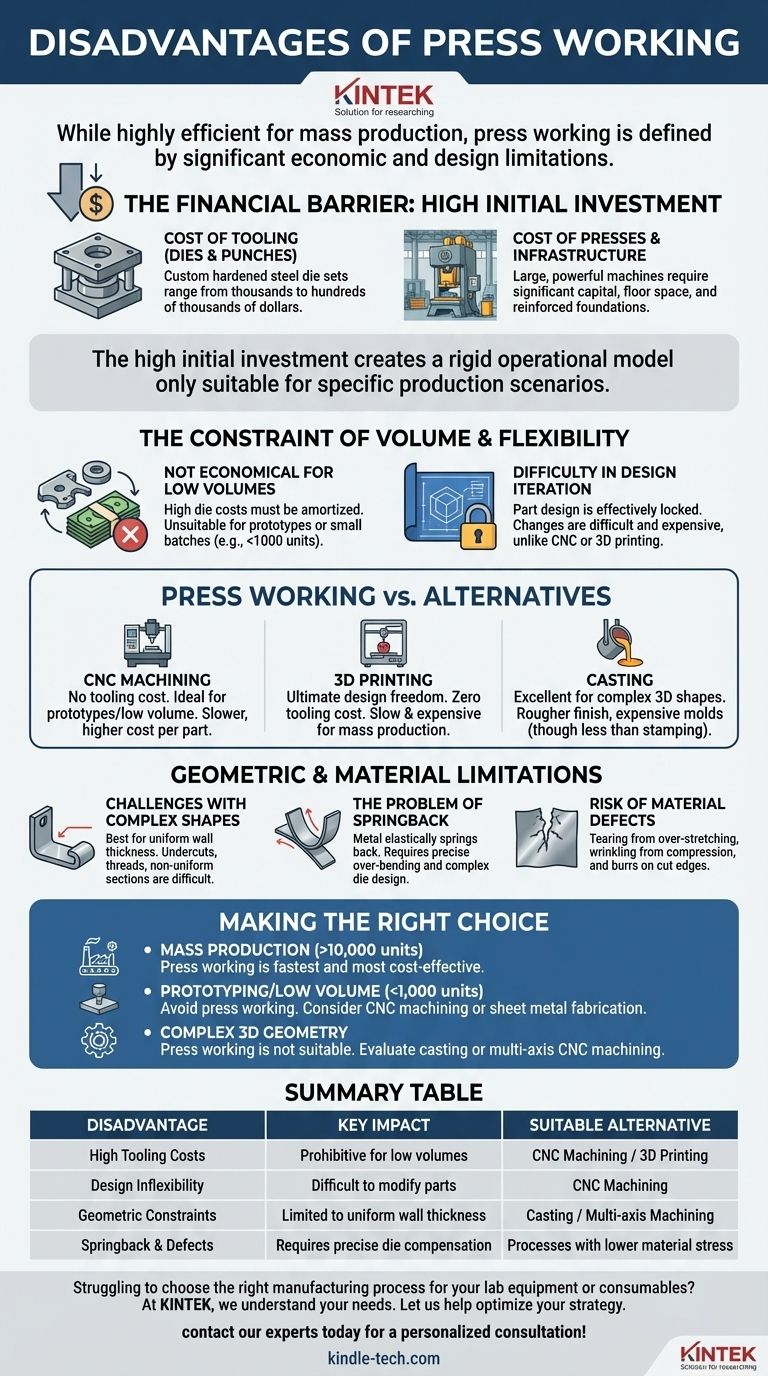

While highly efficient for mass production, press working is defined by its significant economic and design limitations. The primary disadvantages are the exceptionally high initial tooling costs, its lack of economic viability for low-volume production, and its inherent constraints on part geometry and complexity.

Press working offers unparalleled speed and cost-effectiveness at scale, but this efficiency is paid for with high upfront investment and limited design flexibility. Understanding this fundamental trade-off is the key to selecting the right manufacturing process for your needs.

The Financial Barrier: High Initial Investment

The most significant hurdle to adopting press working is the substantial capital required before a single part is produced. This cost is concentrated in the tooling and machinery.

The Cost of Tooling (Dies and Punches)

The core of any press working operation is the die set. This is a custom tool made from hardened steel that precisely forms or cuts the sheet metal.

Designing and manufacturing a production-ready die is a highly specialized and expensive process. Costs can range from thousands to hundreds of thousands of dollars, depending on the part's complexity, size, and required lifespan.

The Cost of Presses and Infrastructure

Beyond the die itself, the process requires large, powerful mechanical or hydraulic presses. These machines are a major capital expense and require significant factory floor space and often reinforced concrete foundations to handle their weight and operational forces.

The Constraint of Volume and Flexibility

The high initial investment creates a rigid operational model that is only suitable for specific production scenarios.

Not Economical for Low Volumes

The high cost of the die must be amortized over the total number of parts produced. This makes press working completely unsuitable for prototypes, small batches, or low-volume production runs.

To be cost-effective, production volumes typically need to be in the tens of thousands, hundreds of thousands, or even millions of units.

Difficulty in Design Iteration

Once a die is manufactured, the part design is essentially locked in. Making even minor changes to the part can be incredibly difficult and expensive, often requiring the die to be extensively re-worked or completely remade.

This lack of flexibility stands in stark contrast to processes like CNC machining or 3D printing, where design changes can be made by simply editing a digital file.

Understanding the Trade-offs: Press Working vs. Alternatives

The disadvantages of press working become clearer when compared to other common manufacturing methods. It is not an inherently "bad" process, but rather a specialized one.

Press Working vs. CNC Machining

CNC machining cuts material from a solid block. It has virtually no tooling cost, making it ideal for prototypes and low volumes. It can also produce far more complex geometries.

However, machining is a much slower process, resulting in a significantly higher cost per part at high volumes compared to the seconds-per-part speed of stamping.

Press Working vs. 3D Printing (Additive Manufacturing)

3D printing offers the ultimate design freedom and is the go-to process for one-off parts and complex prototypes. It has zero tooling costs.

Its primary limitation is speed and material properties. It is currently far too slow and expensive for mass-producing simple metal parts, which is the exact strength of press working.

Press Working vs. Casting

Casting involves pouring molten metal into a mold. It is excellent for creating very complex, thick, or three-dimensional shapes that are impossible to stamp from a sheet.

However, casting generally produces a rougher surface finish and may require secondary machining operations. The tooling for casting (molds) is also expensive, though typically less than high-volume progressive stamping dies.

Geometric and Material Limitations

Even for high-volume parts, press working imposes fundamental constraints on what can be designed.

Challenges with Complex Shapes

Press working is best suited for parts with a relatively uniform wall thickness. Features like undercuts, screw threads, or non-uniform thick sections are extremely difficult or impossible to create in a single stamping process.

The Problem of Springback

After being formed in the die, metal has a tendency to elastically "spring back" slightly towards its original flat shape. Die designers must predict this effect and over-bend the part to compensate, which adds complexity and risk to the tool design phase.

Risk of Material Defects

The process of stretching and bending sheet metal can introduce defects. Tearing can occur if the material is stretched too far, while wrinkling can happen if material compresses improperly. Cut edges also have burrs that may require a secondary deburring process.

Making the Right Choice for Your Project

Selecting the correct process depends entirely on your specific goals for volume, cost, and design complexity.

- If your primary focus is mass production (>10,000 units) of a finalized, relatively simple design: Press working is almost certainly the most cost-effective and fastest solution.

- If your primary focus is prototyping or low-volume production (<1,000 units): Avoid press working due to prohibitive tooling costs; consider CNC machining or sheet metal fabrication (laser cutting and bending).

- If your primary focus is creating a part with highly complex 3D geometry or varying wall thickness: Press working is not suitable; you should evaluate casting or multi-axis CNC machining.

By weighing the high initial costs and design constraints against its incredible speed at scale, you can confidently determine if press working aligns with your production goals.

Summary Table:

| Disadvantage | Key Impact | Suitable Alternative |

|---|---|---|

| High Tooling Costs | Prohibitive for low volumes (<1,000 units) | CNC Machining / 3D Printing |

| Design Inflexibility | Difficult to modify parts after tooling | CNC Machining (digital edits) |

| Geometric Constraints | Limited to uniform wall thickness; no undercuts | Casting / Multi-axis Machining |

| Springback & Defects | Requires precise die compensation; risk of tearing/wrinkling | Processes with lower material stress |

Struggling to choose the right manufacturing process for your lab equipment or consumables? At KINTEK, we understand that selecting between press working, CNC machining, or 3D printing is critical to your project's success. Whether you need high-volume efficiency or flexible prototyping for laboratory tools, our expertise in lab equipment manufacturing ensures you get the most cost-effective and technically suitable solution.

Let us help you optimize your production strategy—contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- How does a rotary tablet press work? A Guide to High-Speed Tablet Manufacturing

- What is die compression ratio? Master Your Pelleting Process for Optimal Quality & Efficiency

- How fast is the rotary tablet press? Unlock Peak Production Speeds for Your Tablets

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production