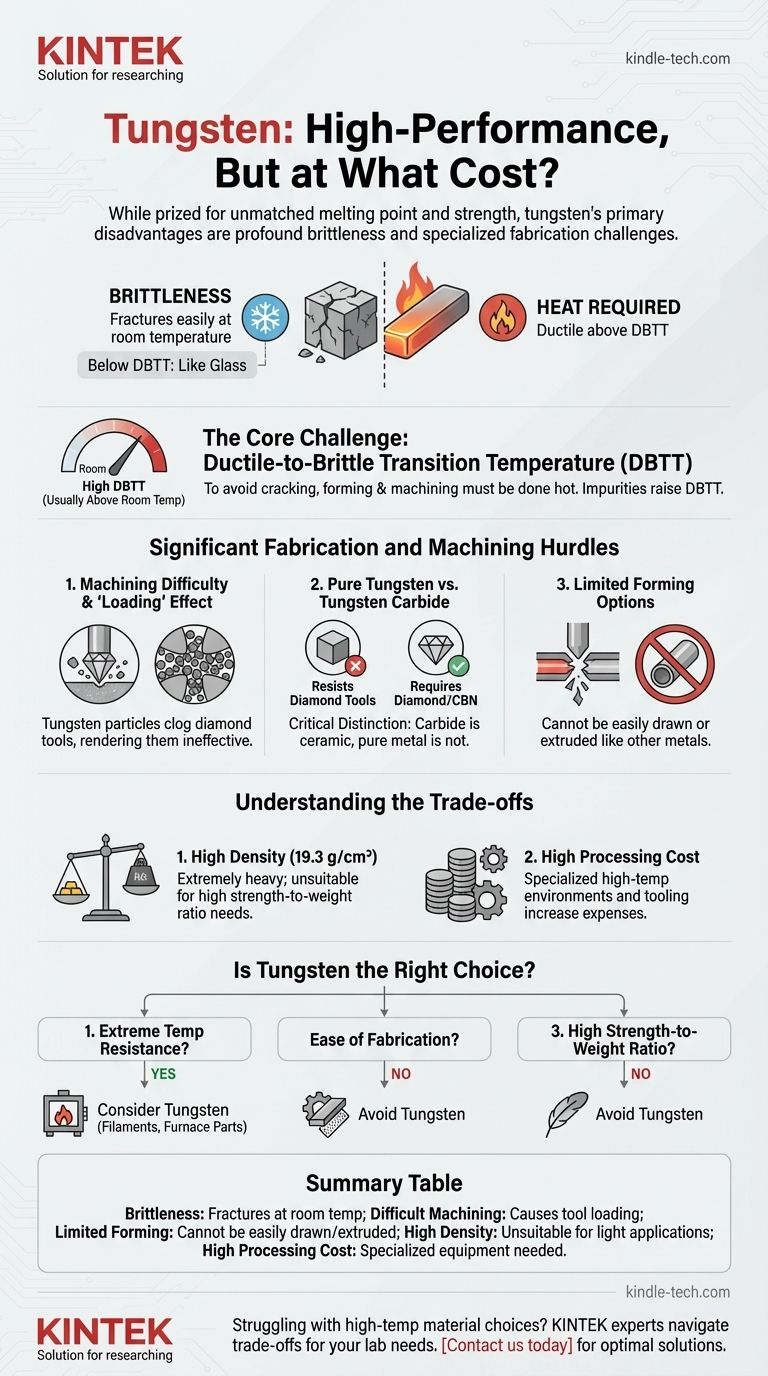

While prized for its unmatched melting point and strength, tungsten's primary disadvantages are its profound brittleness at room temperature and the significant, specialized challenges it presents in machining and fabrication. These properties make it a difficult and expensive material to work with, limiting its applications despite its extreme heat resistance.

Tungsten's incredible thermal stability comes at a direct cost to its workability. The core challenge is that its atomic structure makes it brittle unless heated, and its unique properties render many standard machining and forming techniques ineffective.

The Core Challenge: Brittleness Below a Key Temperature

Tungsten's most significant drawback is not simply that it's hard, but that it's brittle under normal conditions. This behavior is governed by a critical physical property.

Understanding the Ductile-to-Brittle Transition Temperature (DBTT)

Pure tungsten has a DBTT that is typically above room temperature. Below this temperature, the metal behaves like glass, fracturing with little to no deformation. Above this temperature, it becomes ductile and can be bent or shaped.

This means that to avoid cracking, most forming and machining operations on tungsten must be performed while the material is hot, adding complexity and cost to the manufacturing process.

The Impact of Purity

The brittleness of tungsten is highly sensitive to impurities. Any contamination introduced during processing can raise its DBTT even further, making the material more fragile and challenging to handle without fracture.

Significant Fabrication and Machining Hurdles

Even when its brittleness is managed, tungsten presents unique obstacles for shaping and cutting that set it apart from other metals.

Difficulty in Machining Pure Tungsten

A common misconception is that extreme hardness requires diamond tools. While true for many materials, pure tungsten has a unique reaction to them.

The material causes a condition called loading, where tungsten particles compact into the spaces between the diamond abrasives on the tool. This clogs the cutting surface, rendering the tool ineffective almost immediately.

Critical Distinction: Tungsten vs. Tungsten Carbide

It is essential to distinguish pure tungsten metal from tungsten carbide, a ceramic compound made of tungsten and carbon.

Tungsten carbide is exceptionally hard and does require diamond or cubic boron nitride abrasives for shaping. Pure tungsten metal, by contrast, resists these same tools due to the loading effect.

Limitations in Forming and Shaping

Beyond cutting, tungsten's physical properties restrict how it can be formed. It cannot be easily drawn over a mandrel or extruded to create seamless tubing, which is a common process for many other metals.

Understanding the Trade-offs

Choosing tungsten means accepting a difficult balance between its benefits and its inherent drawbacks.

High Density and Weight

Tungsten is one of the densest pure metals, with a density of 19.3 g/cm³, nearly identical to gold. This makes it extremely heavy.

This high weight makes tungsten unsuitable for any application where a high strength-to-weight ratio is critical, such as in many aerospace or automotive components.

The High Cost of Processing

The combination of factors—the need for high-temperature environments, specialized tooling that avoids loading, and limitations on forming methods—makes manufacturing parts from tungsten significantly more expensive than from steel, titanium, or even other refractory metals.

Is Tungsten the Right Choice for Your Application?

Your decision to use tungsten must be based on a clear understanding of whether its primary advantage outweighs its significant limitations.

- If your primary focus is extreme temperature resistance: Tungsten is a premier choice for applications like filaments or furnace parts, but you must budget for high fabrication costs and design around its forming limitations.

- If your primary focus is ease of fabrication: Pure tungsten is a very poor choice, and you should consider alternative refractory metals or high-strength steel alloys.

- If your primary focus is a high strength-to-weight ratio: Tungsten's high density makes it unsuitable; materials like titanium alloys or composites are far better options.

By understanding these fundamental limitations, you can accurately assess whether tungsten's unique strengths justify its significant processing challenges.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Brittleness (High DBTT) | Fractures easily at room temperature; requires hot working. |

| Difficult Machining | Causes tool loading; resists standard cutting methods. |

| Limited Forming Options | Cannot be easily drawn or extruded like other metals. |

| High Density | Unsuitable for applications requiring a high strength-to-weight ratio. |

| High Processing Cost | Specialized equipment and high-temperature handling increase expenses. |

Struggling to choose the right high-temperature material for your lab? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate the trade-offs between tungsten and other refractory metals to find the optimal solution for your specific application—whether it's for furnace components, high-temperature crucibles, or specialized lab tools. Contact us today to discuss your requirements and discover how our expertise can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Single Horizontal Jar Mill

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- How does a vacuum oven contribute to solid electrolyte membrane formation? Achieve Dense, Defect-Free Materials

- What is a magnetron sputtering? A Guide to High-Quality Thin-Film Deposition

- How mechanical properties are affected by sintering? Master the Trade-offs for Stronger Materials

- What is the role of the hydraulic system in hot pressing? Achieve Maximum Material Density and Strength

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification