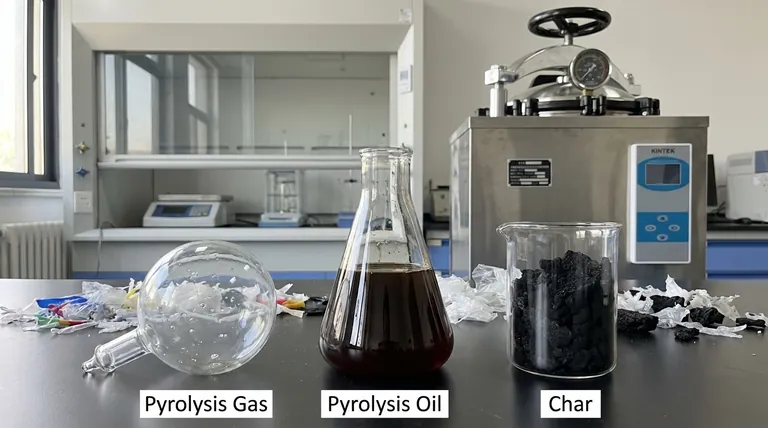

The end products of plastic pyrolysis are three core outputs created by breaking down plastic waste with heat in an oxygen-free environment. This process transforms the plastic into a liquid pyrolysis oil, a non-condensable pyrolysis gas, and a solid carbon residue, often called char. If the initial plastic waste contains moisture, wastewater may also be generated as a separate by-product.

Pyrolysis is not simply a waste disposal method; it is a chemical conversion process. It deconstructs low-value plastic waste into potentially valuable commodities that can be used as fuel or as feedstock for new chemical products.

A Breakdown of the Pyrolysis Outputs

The specific yield and composition of each product depend heavily on the type of plastic feedstock, the process temperature, and the technology used. However, the outputs fall into three predictable categories.

Pyrolysis Oil (The Liquid Fraction)

This is often the primary target product of plastic pyrolysis. It is a complex mixture of hydrocarbon molecules, functionally similar to a synthetic crude oil.

This oil can be used directly as a heavy fuel oil in industrial furnaces or boilers. With further refining, it can be upgraded into more valuable fuels like diesel or even processed to create new plastics and chemicals, supporting a circular economy.

Pyrolysis Gas (The Non-Condensable Fraction)

During the process, a portion of the plastic breaks down into very light molecules that do not condense back into a liquid when cooled. This is the pyrolysis gas.

This gas is a mixture of combustible components like hydrogen (H2), methane (CH4), and other hydrocarbons, along with carbon monoxide (CO) and carbon dioxide (CO2). A key application is to use this gas to power the pyrolysis reactor itself, making the overall process more energy-efficient and self-sustaining.

Carbon Residue (The Solid Fraction)

After the volatile components have been vaporized into oil and gas, a solid, carbon-rich material is left behind. This is commonly referred to as char or carbon black.

The quality of this residue varies, but it can be used as a solid fuel (similar to charcoal), as a filler material in industrial applications, or as a soil amendment (biochar).

Understanding the Key Distinctions

It is critical to distinguish pyrolysis from other thermal processes and to understand what influences the final products.

Pyrolysis vs. Incineration

These two processes are fundamentally different. Incineration is simple combustion; it burns waste in the presence of oxygen to generate heat, which is then used to create electricity.

Pyrolysis, by contrast, is a chemical deconstruction process that occurs without oxygen. It doesn't burn the material but rather breaks down large polymer molecules into smaller, more valuable ones that are captured as new products.

Feedstock Determines Output

The specific type of plastic waste used as feedstock is the single most important factor. Different plastics will produce different ratios of oil, gas, and char.

For example, pyrolyzing polyolefins (like polyethylene and polypropylene) typically yields a high percentage of liquid oil, while other materials might produce more gas or char.

Process Conditions Matter

Operators can "tune" the pyrolysis process to favor a specific output. Higher temperatures and faster heating rates often lead to a higher yield of pyrolysis gas.

Conversely, moderate temperatures and slower rates can be optimized to maximize the production of liquid pyrolysis oil, which is often the most economically valuable product.

Making the Right Choice for Your Goal

Evaluating the end products of pyrolysis requires understanding their potential application and value.

- If your primary focus is creating fuel: The key is to maximize the yield and quality of the pyrolysis oil, which is the most energy-dense and transportable fuel product.

- If your primary focus is chemical recycling: The goal is to produce a high-quality pyrolysis oil that can be efficiently refined into valuable chemical feedstocks for new products.

- If your primary focus is energy self-sufficiency: The crucial step is to effectively capture and reuse the pyrolysis gas to power the entire system, significantly reducing operational costs.

Ultimately, understanding these end products is the first step toward viewing plastic waste not as a liability, but as a valuable resource.

Summary Table:

| Product | Description | Common Uses |

|---|---|---|

| Pyrolysis Oil | A synthetic crude oil mixture | Industrial fuel, refined into diesel, chemical feedstock |

| Pyrolysis Gas | Non-condensable, combustible gas | Powering the pyrolysis reactor, improving energy efficiency |

| Carbon Residue (Char) | Solid, carbon-rich material | Solid fuel, industrial filler, soil amendment (biochar) |

Ready to turn your plastic waste into profit? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you're optimizing oil yield, analyzing gas composition, or characterizing char, our solutions provide the precision and reliability you need. Contact our experts today to discover how we can support your laboratory's journey in chemical recycling and sustainable energy.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Benchtop Laboratory Vacuum Freeze Dryer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What role do laboratory autoclaves play in pectin extraction? Optimize Prebiotic Yield from Citrus and Apple Biomass

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy