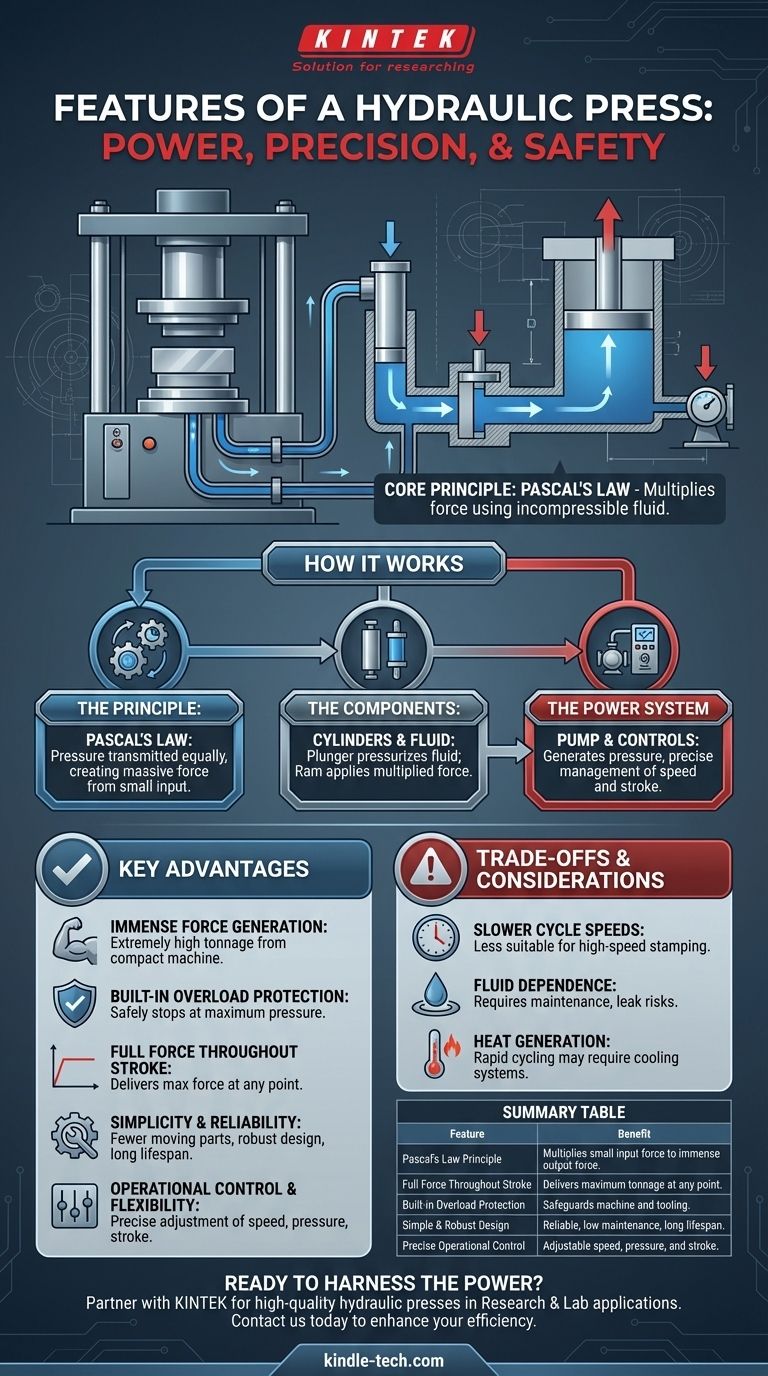

At its core, a hydraulic press is defined by its use of an incompressible fluid to multiply force. It operates on Pascal's principle, where pressure applied to a confined fluid is transmitted undiminished. This allows a small force applied to a small piston (the plunger) to generate an immense force on a larger piston (the ram), enabling tasks like stamping, forging, and molding with relative ease.

The defining feature of a hydraulic press is not just its parts, but the principle it employs. It leverages fluid mechanics to create a simple, powerful, and inherently safe system for generating massive compressive force.

How a Hydraulic Press Generates Force

A hydraulic press is an elegant application of fundamental physics. Its power comes from its method of force transmission, not from complex gears or levers.

The Principle: Pascal's Law

The entire system is governed by Pascal's Law. This principle states that pressure exerted anywhere in a confined, incompressible fluid is transmitted equally in all directions throughout the fluid.

This means a modest pressure created in a small cylinder is perfectly transferred to a large cylinder, where it acts over a much larger area, thus multiplying the force significantly.

The Core Components: Cylinders and Fluid

Every hydraulic press is built around two primary interconnected cylinders of different sizes, filled with hydraulic fluid.

The smaller cylinder is known as the plunger, and the larger one is the ram. When the plunger pushes down on the fluid, it pressurizes the entire system. This pressure then acts on the larger surface area of the ram, creating a powerful upward or downward stroke.

The Power System: Pump and Controls

To create the initial pressure, a hydraulic pump forces fluid into the plunger cylinder. Modern presses feature sophisticated control systems that manage the pump, allowing for precise control over the pressure, speed, and duration of the press stroke.

The Practical Advantages of Hydraulic Design

The simple design principle of a hydraulic press gives rise to several key operational features and benefits that distinguish it from other machine types, like mechanical presses.

Immense Force Generation

The most notable feature is the ability to produce extremely high tonnage in a relatively compact machine. Because force is a product of pressure and area, even a modest hydraulic pressure can generate thousands of tons of force when applied to a large ram.

Built-in Overload Protection

A hydraulic press is naturally protected from overloads. The maximum pressure is determined by a relief valve. The press will simply stop if it encounters resistance that exceeds its set pressure, protecting both the machine and the tooling from damage.

Full Force Throughout the Stroke

Unlike a mechanical press where maximum force is only available at the very bottom of the stroke, a hydraulic press can deliver its full rated force at any point in its travel. This provides greater flexibility for deep-drawing operations or tasks requiring sustained pressure.

Simplicity and Reliability

With fewer moving parts compared to mechanical systems, hydraulic presses have a simple, robust design. This results in lower initial costs, reduced maintenance requirements, and a longer operational lifespan for both the machine and its dies.

Operational Control and Flexibility

Modern hydraulic presses offer exceptional control. Operators can easily adjust the ram speed, stroke length, and pressure. Many systems can be automated, allowing for precise and repeatable cycles for complex forming tasks.

Understanding the Trade-offs

While powerful and versatile, the features of a hydraulic press come with inherent trade-offs that are critical to understand.

Slower Cycle Speeds

Generally, hydraulic presses have slower cycle speeds than mechanical presses. The time it takes for the pump to move the required volume of fluid makes them less suitable for high-speed, high-volume stamping operations.

Dependence on Hydraulic Fluid

The system's lifeblood is its fluid. This requires regular maintenance, including filter changes and fluid monitoring. Leaks can be a significant issue, creating safety hazards and environmental concerns if not managed properly.

Heat Generation

Continuous, rapid cycling of the hydraulic pump generates heat in the fluid. This can affect the fluid's viscosity and system performance, often requiring the integration of a heat exchanger or cooling system for demanding applications.

Making the Right Choice for Your Goal

Understanding these features allows you to determine if a hydraulic press is the correct tool for your specific application.

- If your primary focus is maximum force for forming heavy materials: A hydraulic press is the ideal choice for high-tonnage applications like forging, deep drawing, or compressing large parts.

- If your primary focus is cost-effectiveness and process flexibility: The simple design and ability to control force and stroke length make hydraulic presses a versatile and economical solution for varied or custom jobs.

- If your primary focus is operational safety and tool protection: The built-in overload protection of a hydraulic system provides a significant advantage over mechanical alternatives.

- If your primary focus is high-speed, repetitive production of small parts: A mechanical press will likely offer the higher cycle rates needed for maximum efficiency.

By weighing these core features and trade-offs, you can confidently select the technology best suited to achieve your production goals.

Summary Table:

| Feature | Benefit |

|---|---|

| Pascal's Law Principle | Multiplies a small input force into immense output force. |

| Full Force Throughout Stroke | Delivers maximum tonnage at any point, ideal for deep drawing. |

| Built-in Overload Protection | Safeguards the machine and tooling from damage. |

| Simple & Robust Design | Offers reliability, lower maintenance, and a long lifespan. |

| Precise Operational Control | Adjustable speed, pressure, and stroke for versatile applications. |

Ready to harness the power and reliability of a hydraulic press for your lab or production needs?

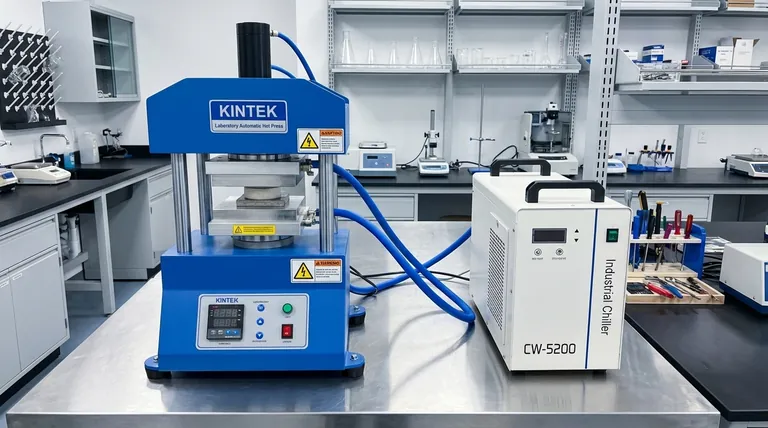

At KINTEK, we specialize in providing high-quality lab equipment, including hydraulic presses tailored for demanding applications like material testing, sample preparation, and R&D. Our expertise ensures you get a solution that delivers the precise force, control, and safety your work requires.

Contact us today via our contact form to discuss how a KINTEK hydraulic press can enhance your efficiency and achieve your production goals.

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Double Plate Heating Press Mold for Lab

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- Can you overload a hydraulic press? Understanding the Critical Risks and Consequences

- Why is graphite powder used in Cu-Al2O3 compression tests? Ensure Accurate Flow Stress and Uniform Deformation

- Why use a laboratory hydraulic press for metal powders? Achieve High-Density Green Bodies for Hot Pressing

- What is the primary function of a four-column hydraulic press? Master Magnesium Alloy Green Body Fabrication

- What is the role of a high-pressure rolling system in ceramic MFC chassis? Ensure Uniformity and Peak Performance

- What can KBr be used as? The Essential Matrix for Accurate FTIR Spectroscopy

- What role does a high-precision laboratory hydraulic press play in ICDP membranes? Optimize Ceramic Support Formation

- Why is a laboratory hydraulic press required for Ru/Cs+/C catalyst preparation? Optimize Density and Performance