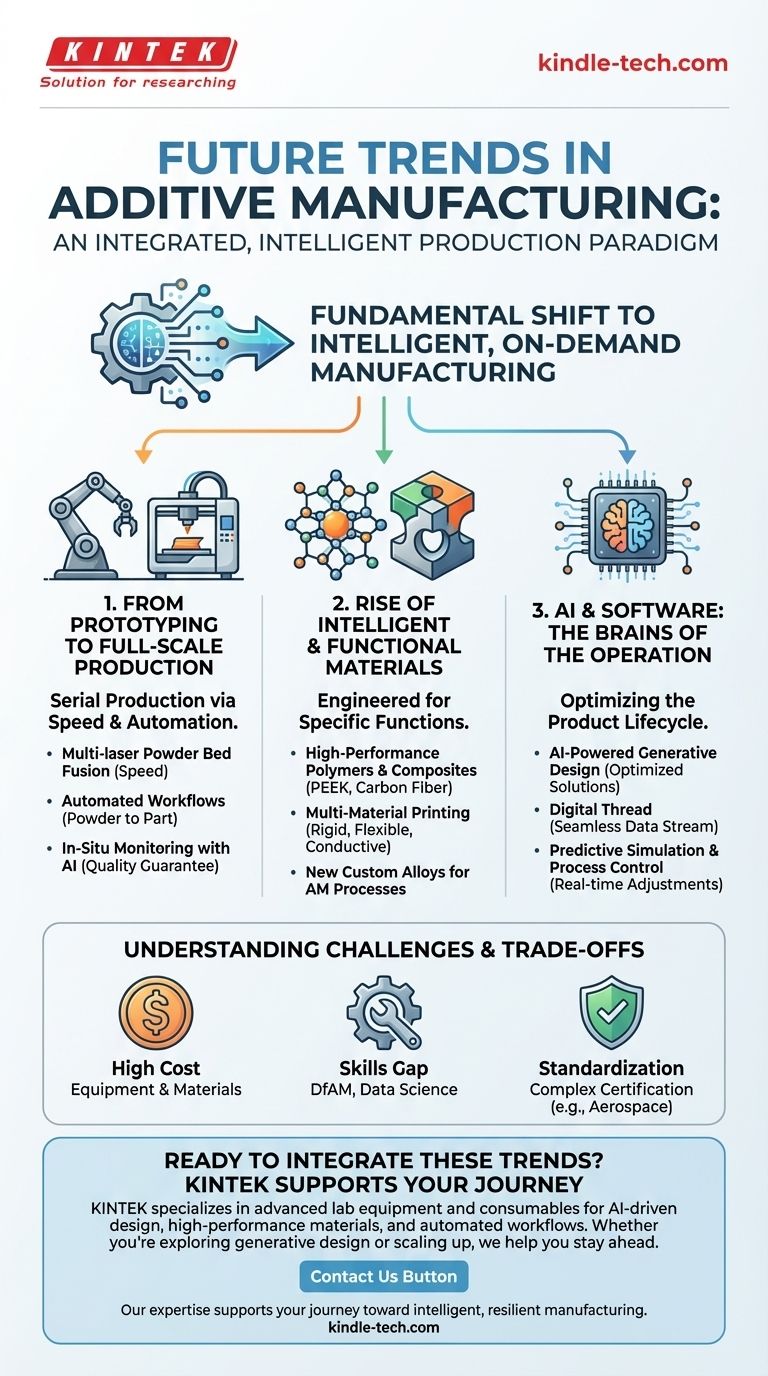

The future of additive manufacturing is a fundamental shift from a prototyping tool to a fully integrated, intelligent production system. The core trends driving this evolution are the integration of artificial intelligence into design and process control, the development of advanced multi-functional materials, and the move towards automated, at-scale production that enables decentralized and resilient supply chains.

Additive manufacturing's future is not just about printing parts faster or cheaper. It's about fundamentally changing how products are designed, what they are made of, and where they are produced, creating a new paradigm of intelligent, on-demand manufacturing.

From Prototyping to Full-Scale Production

The most significant trend in additive manufacturing (AM) is its maturation into a viable method for serial production. This requires overcoming historical limitations in speed, consistency, and automation.

The Push for Speed and Throughput

Early AM processes were too slow for anything but one-off parts. Modern systems are closing this gap with technologies like multi-laser powder bed fusion, which uses multiple lasers simultaneously on a single part, and advancements in binder jetting that dramatically increase volume output for metal components.

Automating the Entire Workflow

True production isn't just about the printing process. The future lies in automating the entire workflow, from powder handling and loading to part removal, post-processing, and inspection. This "lights-out" manufacturing reduces manual labor and increases repeatability.

Guaranteeing Quality with In-Situ Monitoring

For production-grade parts, especially in aerospace and medical fields, quality must be guaranteed. The trend is toward in-situ monitoring, where sensors and cameras watch the build process in real-time. Machine learning algorithms analyze this data to detect potential defects and even make live adjustments to prevent failures.

The Rise of Intelligent and Functional Materials

The materials available for AM are expanding far beyond basic plastics and metals. The next wave involves materials engineered for specific functions and performance, enabling the creation of integrated, intelligent products.

High-Performance Polymers and Composites

Materials like PEEK, PEKK, and carbon-fiber-reinforced polymers are increasingly used to print strong, lightweight parts that can replace metal in demanding applications. These materials offer excellent chemical resistance and thermal stability.

Printing with Multiple Materials

The ability to print a single component using multiple materials is a transformative trend. This allows for parts with both rigid and flexible sections, integrated electrical conductivity for embedded sensors, or varying thermal properties within one object.

Designing Alloys for Additive Processes

Instead of adapting traditional alloys for AM, researchers are now creating new metal alloys specifically designed for the layer-by-layer fusion process. These materials can achieve microstructures and properties impossible to create with casting or forging.

AI and Software: The Brains of the Operation

Software, particularly artificial intelligence, is becoming the central nervous system of modern additive manufacturing. It's moving beyond simple slicing to optimizing every aspect of the product lifecycle.

AI-Powered Generative Design

Generative design uses AI algorithms to create thousands of potential design solutions based on a set of constraints like load, weight, and manufacturing method. This results in highly optimized, organic-looking parts that are often lighter and stronger than anything a human could design.

The Emergence of the Digital Thread

The digital thread is the concept of a single, seamless stream of data that connects every stage from initial design to simulation, production, and in-service performance. This creates a powerful feedback loop, where performance data from a real-world part can inform the design of the next generation.

Predictive Simulation and Process Control

Software can now accurately simulate the printing process before it begins, predicting thermal stresses and potential distortions. During the print, AI can use sensor data to compare the actual build to the simulation, making real-time parameter adjustments to ensure the final part matches the digital model perfectly.

Understanding the Challenges and Trade-offs

While the future is promising, several critical challenges must be addressed for AM to reach its full potential as a mainstream production method.

The High Cost of Equipment and Materials

Cutting-edge industrial AM systems and high-performance materials remain a significant capital investment. The cost per part is still higher than traditional methods for many high-volume applications.

Bridging the Skills Gap

The workforce needs new skills to capitalize on these trends. Expertise in Design for Additive Manufacturing (DfAM), data science, materials science, and automation engineering is in high demand and short supply.

The Hurdle of Standardization and Certification

For critical industries like aerospace and healthcare, certifying AM parts is a complex and lengthy process. The industry is working to establish clear standards for processes, materials, and testing to streamline qualification.

How to Apply This to Your Goal

The right trend to focus on depends entirely on your strategic objectives.

- If your primary focus is product innovation and performance: Immediately invest in training your engineering team on generative design and exploring the possibilities of multi-material printing.

- If your primary focus is manufacturing efficiency and supply chain resilience: Evaluate new, high-throughput AM systems and begin pilot projects for on-demand production of spare parts or low-volume components.

- If your primary focus is business strategy and new markets: Analyze how mass customization and distributed manufacturing could unlock entirely new business models for your company.

Ultimately, these trends are converging to create a manufacturing ecosystem that is more agile, customizable, and resilient than ever before.

Summary Table:

| Key Trend | Core Focus | Key Technologies |

|---|---|---|

| Production Integration | Shifting from prototyping to serial production | Multi-laser systems, automated workflows, in-situ monitoring |

| Intelligent Materials | Expanding beyond basic plastics/metals | High-performance polymers, multi-material printing, custom alloys |

| AI & Software | Optimizing design and process control | Generative design, digital thread, predictive simulation |

| Challenges | Addressing barriers to adoption | Cost, skills gap, standardization |

Ready to integrate these additive manufacturing trends into your lab or production line? KINTEK specializes in providing the advanced lab equipment and consumables needed to leverage AI-driven design, high-performance materials, and automated workflows. Whether you're exploring generative design or scaling up for production, our expertise supports your journey toward intelligent, resilient manufacturing. Contact us today to discuss how we can help you stay ahead in the evolving AM landscape!

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- High Performance Laboratory Freeze Dryer

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How does a high-speed homogenizer prepare m-BN and PNF dispersions? Achieve Uniform Molecular-Level Integration

- What is a sintered metal? A Guide to High-Strength, Complex Metal Parts

- What is an example of a magnetron sputtering? Creating High-Performance Coatings for Eyeglasses & Electronics

- Does pressure affect melting and boiling? Master Phase Changes with Pressure Control

- What does CIP stand for Crip? Understanding the Meaning of Crip In Peace

- What is the function of a laboratory precision oven in GLYMO-rGO preparation? Ensure Optimal Nano-Filler Dispersion

- Why is a vacuum drying oven necessary for Pt/Nb-TiO2 catalyst preparation? Optimize Your Material Activity

- What does the acronym CVD stand for? Decoding Its Meaning in Medicine and Technology