Proper maintenance of a super-sealed electrolytic cell is fundamental to achieving accurate and repeatable experimental results. The core procedures involve regular inspection of all components for damage, consistent cleaning to remove residues, strategic replacement of the electrolyte to prevent impurity buildup, and careful handling and storage to protect the fragile glass cell and sensitive electrodes.

The goal of a maintenance routine isn't just to keep the equipment clean; it's to guarantee the integrity of your electrochemical system. Meticulous care prevents contamination, ensures component longevity, and is the foundation of reliable, reproducible data.

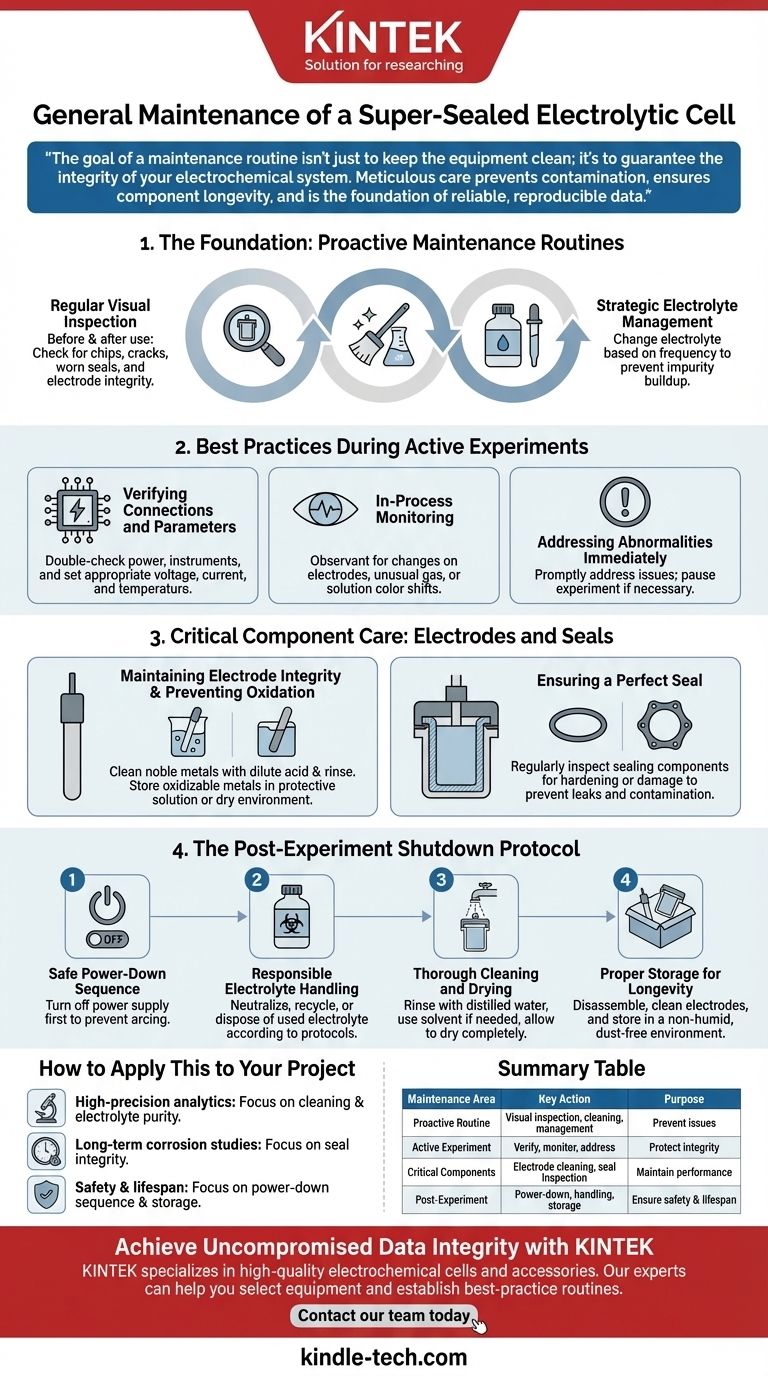

The Foundation: Proactive Maintenance Routines

A consistent, proactive approach to maintenance prevents most common issues before they can compromise your experiments.

Regular Visual Inspection

Before and after each use, perform a quick but thorough inspection. Check the glass cell for any chips or cracks. Examine all seals for signs of aging, wear, or damage, and ensure electrodes are not bent, scratched, or loose.

Consistent Cleaning Protocols

Regularly clean the cell's exterior surfaces to remove dust and electrolyte residue, which helps prevent long-term corrosion. The interior must be cleaned meticulously after each experiment to avoid cross-contamination.

Strategic Electrolyte Management

The electrolyte should be changed based on usage frequency and the nature of your experiments. Buildup of impurities or reaction byproducts can significantly alter electrochemical behavior and lead to inaccurate results.

Best Practices During Active Experiments

Careful operation is a form of active maintenance that protects both the equipment and the data.

Verifying Connections and Parameters

Before starting, always double-check that the cell is correctly connected to the power supply and any detection instruments. Ensure that experimental parameters like voltage, current, and temperature are set appropriately for your specific requirements.

In-Process Monitoring

During the experiment, remain observant. Watch for unexpected changes on the electrode surfaces, unusual gas generation, or shifts in the solution's color. These can be early indicators of a problem.

Addressing Abnormalities Immediately

If you observe any abnormalities, address them promptly. This may involve pausing the experiment to correct an issue, which is far better than completing a run with compromised data.

Critical Component Care: Electrodes and Seals

The electrodes and seals are the most sensitive parts of the assembly and require special attention.

Maintaining Electrode Integrity

Avoid bumping or scratching electrode surfaces. After use, clean them according to their material; for noble metals like platinum, soaking in a dilute acid (e.g., 1M nitric acid) followed by a thorough rinse with deionized water is effective.

Preventing Oxidation

For metal electrodes prone to oxidation, proper storage is key. When not in use, they can be kept in a protective solution or stored in a dry, oxygen-free environment to maintain their performance.

Ensuring a Perfect Seal

The "super-sealed" nature of the cell is critical. Regularly inspect all sealing components (like O-rings or gaskets) for hardening or damage. A tight seal is essential to prevent electrolyte leaks and atmospheric contamination.

The Post-Experiment Shutdown Protocol

A disciplined shutdown process is non-negotiable for safety and extending the life of your equipment.

Safe Power-Down Sequence

Always turn off the power supply first, before disconnecting the circuit or other instruments. This simple step prevents electrical arcing and potential damage to your equipment.

Responsible Electrolyte Handling

After powering down, handle the used electrolyte according to its properties. This may involve neutralization, recycling, or disposal following established safety and environmental protocols.

Thorough Cleaning and Drying

Pour out the remaining electrolyte and rinse the cell multiple times with distilled water. If necessary, use a suitable solvent to remove stubborn residues. Allow the cell and all components to dry completely.

Proper Storage for Longevity

Disassemble the electrodes, clean them, and store them properly. The clean, dry electrolytic cell should be kept in a non-humid, dust-free environment to await its next use.

How to Apply This to Your Project

Your maintenance focus may shift slightly depending on your experimental goals.

- If your primary focus is high-precision analytics: Meticulous cleaning and ensuring electrolyte purity are your most critical tasks to prevent contamination.

- If your primary focus is long-term corrosion studies: Seal integrity is paramount to prevent atmospheric interference over extended experimental runs.

- If your primary focus is safety and equipment lifespan: Adhering strictly to the power-down sequence and proper storage protocols will prevent accidents and degradation.

Ultimately, disciplined maintenance transforms your electrolytic cell from a simple piece of glassware into a reliable scientific instrument.

Summary Table:

| Maintenance Area | Key Action | Purpose |

|---|---|---|

| Proactive Routine | Visual inspection, cleaning, electrolyte management | Prevent issues before they start |

| Active Experiment | Verify connections, monitor process, address abnormalities | Protect equipment and data integrity during use |

| Critical Components | Electrode cleaning, seal inspection, oxidation prevention | Maintain sensitive parts for accurate performance |

| Post-Experiment | Safe power-down, responsible electrolyte handling, proper storage | Ensure safety and extend equipment lifespan |

Achieve Uncompromised Data Integrity with KINTEK

Your research depends on the precision of your equipment. KINTEK specializes in high-quality lab equipment and consumables, including electrochemical cells and accessories, designed for reliability and ease of maintenance.

Let our experts help you select the right equipment and establish best-practice maintenance routines to protect your investment and ensure your experiments yield accurate, reproducible results every time.

Contact our team today to discuss your laboratory's specific needs and discover how KINTEK can support your success.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- H Type Electrolytic Cell Triple Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- How should the five-port water bath electrolytic cell be cleaned for maintenance? A Step-by-Step Guide to Reliable Results

- What are the proper storage procedures for the multifunctional electrolytic cell? Protect Your Investment and Ensure Data Accuracy

- How can contamination be avoided during experiments with the five-port water bath electrolytic cell? Master the 3-Pillar Protocol

- What material is the five-port water bath electrolytic cell made of? High Borosilicate Glass & PTFE Explained

- What general precaution should be taken when handling the electrolytic cell? Ensure Safe and Accurate Lab Results