At its core, brazing introduces significant chemical and physical hazards that every operator must understand and mitigate. The primary risks stem from the toxic fumes generated by heating metals and fluxes, intense thermal and light radiation from the heat source, and the ever-present danger of severe burns and fires.

The most critical takeaway is that brazing hazards are not isolated to a single source. They are a combination of chemical exposures from fumes, physical dangers from heat and radiation, and process risks from compressed gases and chemicals, all of which require a multi-layered safety approach.

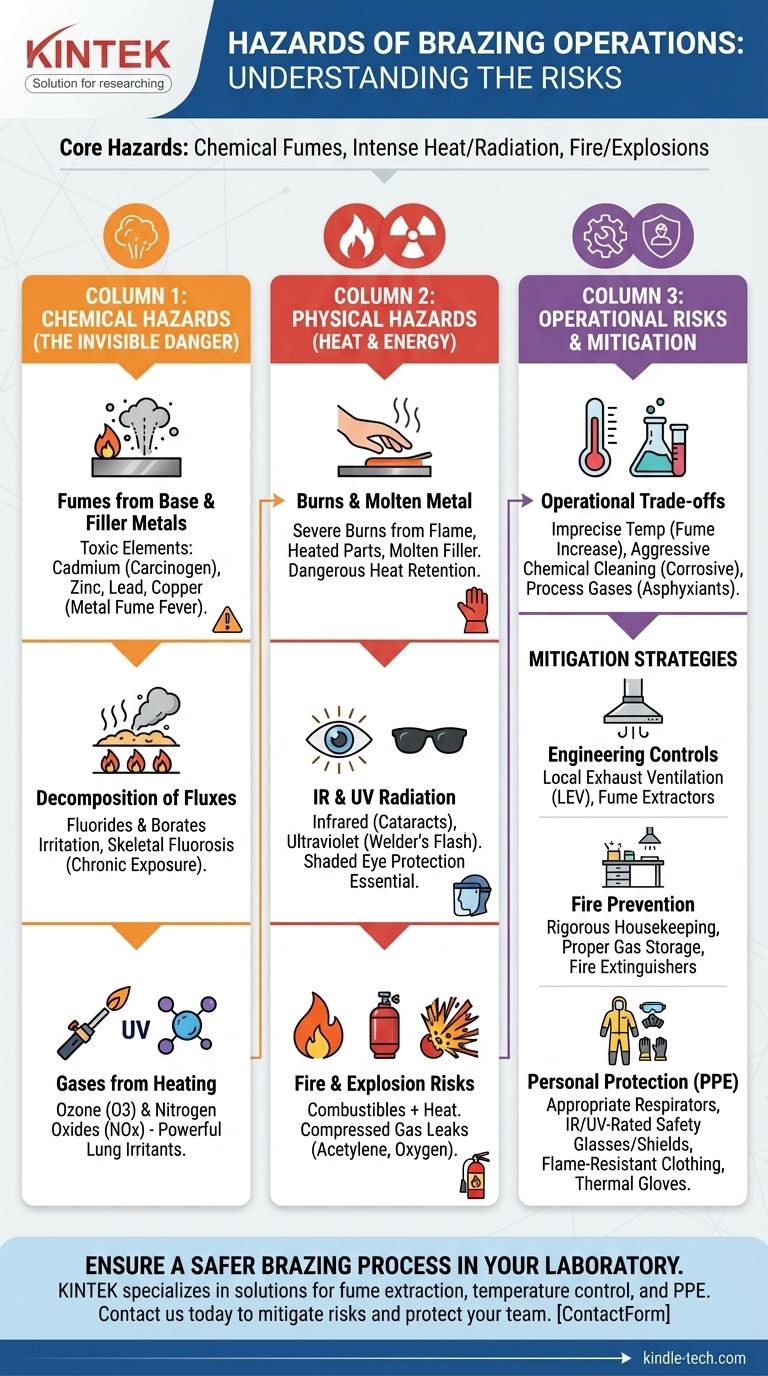

Chemical Hazards: The Invisible Danger

The most insidious dangers in brazing are often the ones you cannot see. Fumes and gases released during the heating process can cause severe, long-term health effects if not properly controlled.

Fumes from Base and Filler Metals

Many filler metals contain toxic elements. When heated, these metals vaporize and can be inhaled as a fine particulate fume.

Cadmium, historically used in some silver-based fillers, is extremely toxic and a known carcinogen. Exposure can cause severe lung damage and kidney failure. Modern operations should use cadmium-free alloys whenever possible.

Other metals like zinc, lead, and copper can also produce harmful fumes, leading to conditions like "metal fume fever," which presents with flu-like symptoms.

Decomposition of Fluxes

Brazing fluxes are chemical compounds used to clean the base metal and prevent oxidation. When heated, these fluxes decompose and release their own set of hazardous fumes.

Fluxes often contain fluorides and borates. Inhaling fluoride compounds can irritate the respiratory system, and chronic exposure can lead to skeletal fluorosis, a painful bone disease.

Gases from the Heating Process

The high temperatures involved in torch or furnace brazing can react with the surrounding air to create harmful gases.

Ozone (O3) and nitrogen oxides (NOx) can be formed by the interaction of high heat or UV radiation with air. Both are powerful lung irritants that can cause short-term breathing difficulty and long-term respiratory damage.

Physical Hazards: Managing Heat and Energy

The physical dangers of brazing are more obvious but no less serious. They involve the direct transfer of thermal and light energy.

Burns and Molten Metal

Contact with the torch flame, heated parts, or molten filler metal will cause severe burns. Even after the heat source is removed, parts remain dangerously hot for a significant period.

Proper handling procedures and thermal-insulating gloves are non-negotiable to prevent skin contact.

Infrared and Ultraviolet Radiation

Brazing operations, especially torch and induction methods, emit intense infrared (IR) radiation (heat) and, in some cases, ultraviolet (UV) radiation.

Prolonged exposure to IR can damage the lens of the eye, leading to cataracts. UV radiation can cause "welder's flash" (photokeratitis), a painful inflammation of the cornea. Shaded eye protection is essential.

Fire and Explosion Risks

The combination of an open flame or high-temperature equipment with flammable materials presents a constant fire risk. The work area must be clear of solvents, oils, rags, and other combustibles.

Furthermore, the use of compressed gas cylinders (like acetylene, oxygen, or propane) carries a risk of leaks and explosions if they are mishandled, damaged, or stored improperly.

Understanding the Operational Trade-offs

The technical challenges of a specific brazing job can introduce secondary safety hazards that must be managed.

The Risk of Imprecise Temperature Control

As noted with aluminum brazing, the melting points of the base and filler metals can be very close. Overheating not only ruins the part but also dramatically increases the rate of fume generation, creating a more hazardous breathing zone for the operator.

Aggressive Chemical Cleaning

To braze materials like aluminum, a stubborn oxide layer must often be removed with strong alkaline or acidic chemicals. These pre-cleaning and post-cleaning agents are corrosive and present their own handling, storage, and disposal hazards.

Process-Specific Gas Atmospheres

Controlled atmosphere or vacuum brazing mitigates some oxidation issues but introduces new risks. These include handling inert gases like argon or nitrogen, which can act as asphyxiants in enclosed spaces, or managing the high-pressure systems of a vacuum furnace.

Making the Right Choice for a Safe Operation

Your safety strategy must be comprehensive, addressing the specific materials, fluxes, and heating methods you use.

- If your primary focus is operator health: Prioritize engineering controls like local exhaust ventilation (LEV) or fume extractors to capture hazardous fumes at the source.

- If your primary focus is fire prevention: Enforce rigorous housekeeping, ensure proper storage of gas cylinders and flammable liquids, and have appropriate fire extinguishers readily accessible.

- If your primary focus is personal protection: Mandate and provide correct Personal Protective Equipment (PPE), including appropriate respirators for the fumes present, IR/UV-rated safety glasses or face shields, and flame-resistant clothing with thermal gloves.

Ultimately, a safe brazing operation is an informed and disciplined one.

Summary Table:

| Hazard Category | Specific Risks | Key Mitigation Strategies |

|---|---|---|

| Chemical Hazards | Toxic fumes (cadmium, zinc), flux decomposition (fluorides), ozone/nitrogen oxides | Use cadmium-free alloys, local exhaust ventilation, proper respirators |

| Physical Hazards | Severe burns, IR/UV radiation, fire/explosion from gases | Thermal gloves, IR/UV-rated eye protection, strict housekeeping |

| Operational Risks | Imprecise temperature control, aggressive chemical cleaning, asphyxiant gases | Precise temperature monitoring, safe chemical handling procedures |

Ensure a safer brazing process in your laboratory. The hazards of brazing—from toxic fumes to intense radiation—require robust safety protocols and reliable equipment. KINTEK specializes in lab equipment and consumables, serving laboratory needs with solutions that enhance operator safety. Whether you need fume extraction systems, temperature-controlled furnaces, or personal protective equipment, we provide the tools for a secure and efficient operation. Contact us today to discuss how we can help you mitigate brazing risks and protect your team.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What are the different types of brazing welding? A Guide to Choosing the Right Heat Source