The primary hazards of copper brazing are material degradation and the creation of undetectable leaks. These issues arise when using non-oxygen-free grades of copper, where internal oxides react with brazing atmospheres to form water vapor, causing blisters and internal fissures. This damage can then allow brazing filler metal to penetrate the copper's grain boundaries, creating hidden leak paths that compromise the integrity of the final assembly.

The most critical takeaway is that the majority of copper brazing hazards are not inherent to the process itself, but are a direct result of selecting the wrong grade of copper for the application. Understanding the material science is the key to preventing catastrophic failures.

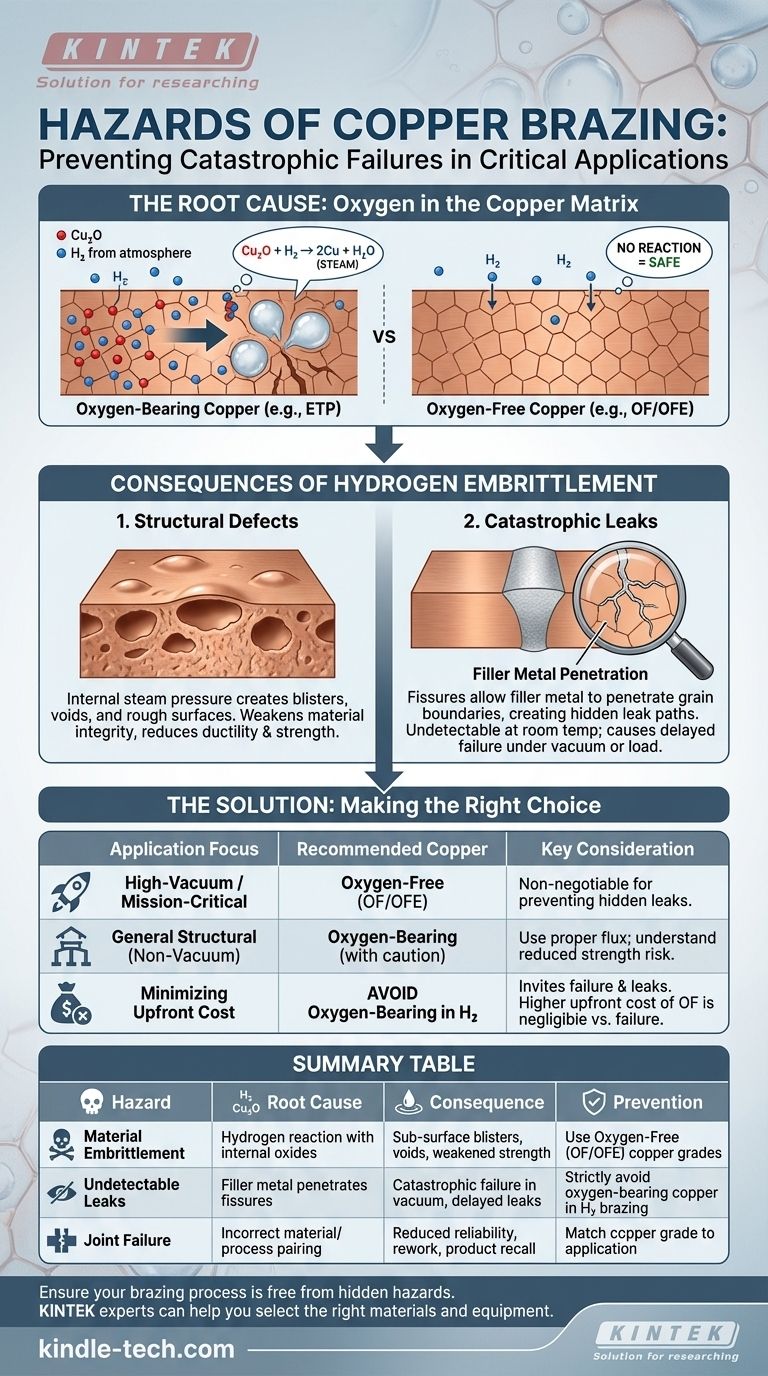

The Root Cause: Oxygen in the Copper Matrix

The most significant hazards in copper brazing trace back to one element: oxygen trapped within the copper itself during its initial manufacturing.

Understanding Copper Grades

Not all copper is the same. The critical distinction is between Oxygen-Free (OF) copper, such as C10100 or C10200, and more common, oxygen-bearing grades like ETP (Electrolytic Tough Pitch) copper.

OF copper has its oxygen content strictly controlled to minuscule levels. ETP copper, while having excellent conductivity, contains oxygen in the form of copper oxide (Cu₂O) inclusions within its metallic structure.

The Hydrogen Embrittlement Reaction

Many high-purity brazing operations occur in a reducing atmosphere, such as hydrogen, to prevent oxidation. When oxygen-bearing copper is heated in this environment, the hydrogen atoms diffuse into the copper and react with the internal copper oxide inclusions.

This chemical reaction (Cu₂O + H₂ → 2Cu + H₂O) produces high-pressure water vapor (steam). Because this steam is trapped within the solid metal, it creates immense internal pressure, leading to significant material damage.

Consequence 1: Physical and Structural Defects

The internal pressure from the steam formation manifests as visible and structural failures that compromise the part.

Blisters, Voids, and Roughness

The trapped water vapor forces the copper apart, creating sub-surface voids and blisters. On the surface, this can appear as bumps or a rough, uneven texture where a smooth finish is expected.

Weakened Material Integrity

These internal voids and fissures are points of weakness. They reduce the material's ductility and strength, making the brazed component susceptible to cracking or failure under mechanical stress or thermal cycling.

Consequence 2: Catastrophic Vacuum Leaks

For applications in vacuum systems, aerospace, or electronics, the most insidious hazard is the creation of leak paths that are nearly impossible to find.

Filler Metal Penetration

The internal fissures created by hydrogen embrittlement act as pathways. During brazing, the liquid filler metal is drawn into these newly opened grain boundaries and micro-cracks by capillary action.

From the outside, the braze joint may look perfect. Internally, however, the filler metal has created a complex, microscopic network of leak paths straight through the base copper material itself.

The Challenge of Detection

These leaks are often too small to be found with standard helium leak detectors at room temperature. However, they can open up when the component is heated or put under vacuum or mechanical load, leading to a delayed and catastrophic failure in the field.

Understanding the Trade-offs

Choosing the right material and process requires balancing cost, performance, and risk.

The Cost vs. Reliability Equation

The primary reason to use oxygen-bearing copper is its lower cost compared to OF grades. However, this cost saving introduces a significant and often unacceptable risk of embrittlement and leakage.

For any critical application, the higher upfront cost of OF copper is negligible compared to the potential cost of a field failure, rework, or product recall.

The Importance of Process Control

Even with the correct material, poor process control can introduce hazards. Inadequate cleaning can leave surface oxides that inhibit filler flow, while using the wrong brazing atmosphere can cause its own set of problems. The material and the process must be considered together.

Making the Right Choice for Your Goal

Your choice of copper should be dictated entirely by the end-use requirements of the component.

- If your primary focus is high-vacuum performance or mission-critical reliability: You must use an Oxygen-Free (OF or OFE) grade of copper. This is non-negotiable.

- If your primary focus is a general structural joint not used in a vacuum: An oxygen-bearing copper may be acceptable, but you must use a proper flux and understand the risk of reduced material strength.

- If your primary focus is minimizing upfront cost: Be aware that using oxygen-bearing copper in a hydrogen brazing environment directly invites material failure and undetectable leaks.

Ultimately, preventing the hazards of copper brazing comes down to selecting the correct material for the process you intend to use.

Summary Table:

| Hazard | Root Cause | Consequence | Prevention |

|---|---|---|---|

| Material Embrittlement | Hydrogen reaction with internal oxides (Cu₂O) in copper | Sub-surface blisters, voids, weakened strength | Use Oxygen-Free (OF/OFE) copper grades (C10100, C10200) |

| Undetectable Leaks | Filler metal penetrates fissures created by steam pressure | Catastrophic failure in vacuum systems, delayed leaks | Strictly avoid oxygen-bearing copper (e.g., ETP) in hydrogen brazing |

| Joint Failure | Incorrect material/process pairing | Reduced reliability, rework, product recall | Match copper grade to application (OF for critical/vacuum use) |

Ensure your brazing process is free from hidden hazards. KINTEK specializes in lab equipment and consumables, serving critical laboratory and R&D needs. Our experts can help you select the right materials and equipment to prevent copper brazing failures. Contact us today to discuss your specific application and achieve reliable, leak-free results.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining

- What is oxidation in brazing? How to prevent it for strong, durable joints

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing