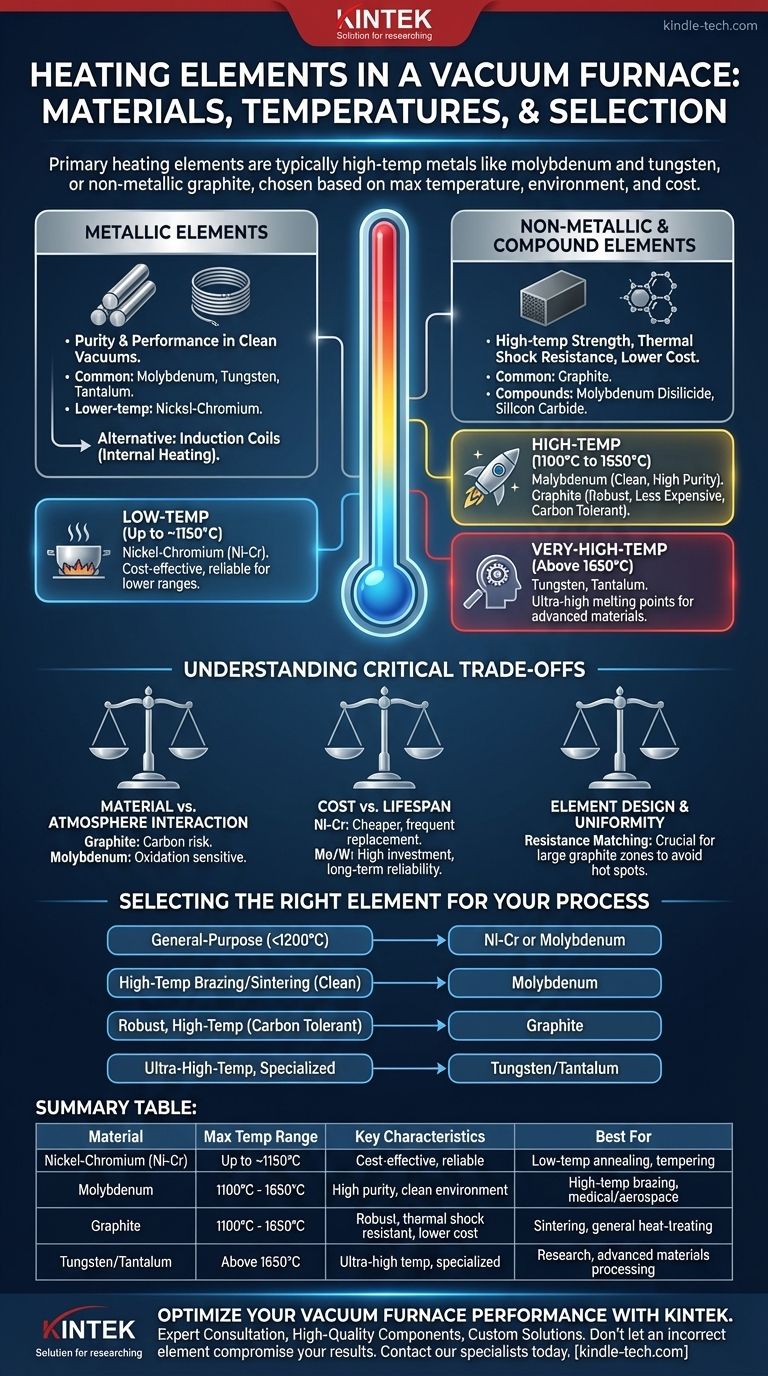

The primary heating elements in a vacuum furnace are typically constructed from high-temperature metals like molybdenum and tungsten, or from non-metallic graphite. Other materials such as nickel-chromium alloys are used for lower temperatures, while exotic refractory metals like tantalum are reserved for very high-temperature, specialized applications. The final choice is dictated by the maximum operating temperature, the chemical environment inside the furnace, and cost.

The selection of a vacuum furnace heating element is not a simple choice of material, but a critical engineering decision. The right element balances the maximum required operating temperature against chemical compatibility with the material being processed and overall operational cost.

The Two Fundamental Classes of Heating Elements

Vacuum furnace heating elements fall into two main categories: metallic and non-metallic. While both use electrical resistance to generate heat, their properties make them suitable for very different applications.

Metallic Elements

Metallic elements are prized for their purity and performance in extremely clean vacuum environments.

Common metals include molybdenum, tungsten, and tantalum. For lower-temperature processes, more common alloys like nickel-chromium are also used. These are often manufactured as rods, wires, or ribbons.

Non-Metallic and Compound Elements

The most common non-metallic element is graphite, which is valued for its high-temperature strength, low cost, and resistance to thermal shock.

Other non-metallic elements are compounds like molybdenum disilicide (from silicon molybdenum rods) and silicon carbide, which offer unique properties for specific atmospheric conditions.

Alternative Heating Methods

Some furnaces utilize methods beyond simple resistance heating.

Induction coils, for example, do not heat the furnace chamber directly. Instead, they generate an electromagnetic field that induces current within the metallic workpiece itself, causing it to heat up from the inside out.

How Temperature Dictates Material Choice

The single most important factor in selecting a heating element is the required operating temperature. Each material has a distinct and practical upper limit.

Low-Temperature Applications (Up to ~1150°C)

For processes like tempering and annealing, nickel-chromium (Ni-Cr) alloys are a common and cost-effective choice.

They provide reliable heating in the lower temperature ranges but will quickly degrade if pushed beyond their specified limits.

High-Temperature Applications (1100°C to 1650°C)

This is the most common range for vacuum furnace work, dominated by two materials: molybdenum and graphite.

Molybdenum is ideal for processes requiring high cleanliness, such as medical implant or aerospace component manufacturing. Graphite is a robust and less expensive workhorse, suitable for applications like sintering and general heat-treating where carbon interaction is not a concern.

Very-High-Temperature Applications (Above 1650°C)

When temperatures exceed the capabilities of molybdenum, refractory metals are required.

Tungsten and tantalum have extremely high melting points, making them essential for specialized applications in research and advanced materials processing. They are significantly more expensive and can be more difficult to work with.

Understanding the Critical Trade-offs

Choosing an element involves more than just looking at a temperature chart. You must consider the interaction between the element, the atmosphere, and the workpiece.

Material vs. Atmosphere Interaction

The wrong element can contaminate your product. Graphite elements, for instance, can introduce carbon into the furnace environment, which can be detrimental to certain metal alloys.

Conversely, a small amount of oxygen or water vapor at high temperatures can rapidly oxidize and destroy a molybdenum element, while a graphite element would be unaffected.

Cost vs. Lifespan

There is a direct relationship between an element's cost and its performance longevity.

Inexpensive nickel-chromium elements may require frequent replacement if operated near their limit. A precisely designed molybdenum or tungsten hot zone, while carrying a high initial cost, is an investment in long-term reliability and process purity.

Element Design and Uniformity

The physical shape and electrical properties of the element are critical. For large graphite hot zones, resistance matching of the curved elements is crucial.

Mismatched resistance can create hot or cold spots within the furnace, leading to non-uniform heating of the workload and inconsistent product quality.

Selecting the Right Element for Your Process

Your specific industrial or research goal is the ultimate guide to selecting the correct heating element.

- If your primary focus is general-purpose heat treating below 1200°C: Nickel-chromium or molybdenum elements offer the best balance of cost and performance.

- If your primary focus is high-temperature brazing or sintering in a clean environment: Molybdenum is the industry standard due to its stability and low contamination risk.

- If your primary focus is robust, high-temperature applications that can tolerate carbon: Graphite provides excellent performance, thermal shock resistance, and a lower overall cost.

- If your primary focus is ultra-high-temperature or highly specialized processes: Refractory metals like tungsten or tantalum are necessary to achieve the required temperatures and performance.

Ultimately, understanding these material properties and trade-offs empowers you to make an informed engineering decision for your specific application.

Summary Table:

| Material | Max Temperature Range | Key Characteristics | Best For |

|---|---|---|---|

| Nickel-Chromium (Ni-Cr) | Up to ~1150°C | Cost-effective, reliable | Low-temp annealing, tempering |

| Molybdenum | 1100°C - 1650°C | High purity, clean environment | High-temp brazing, medical/aerospace |

| Graphite | 1100°C - 1650°C | Robust, thermal shock resistant, lower cost | Sintering, general heat-treating |

| Tungsten/Tantalum | Above 1650°C | Ultra-high temp, specialized | Research, advanced materials processing |

Optimize Your Vacuum Furnace Performance with KINTEK

Selecting the correct heating element is critical for achieving consistent results, maintaining process purity, and controlling operational costs. The experts at KINTEK specialize in lab equipment and consumables, and can help you navigate the trade-offs between temperature, atmosphere, and material compatibility.

We provide:

- Expert Consultation to match the ideal heating element to your specific application.

- High-Quality Components including molybdenum, graphite, and tungsten elements for reliability and longevity.

- Custom Solutions designed for your unique laboratory or industrial process needs.

Don't let an incorrect heating element compromise your results. Contact our specialists today to ensure your vacuum furnace operates at peak performance.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Laboratory High Pressure Vacuum Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the primary function of a vacuum arc furnace in the preparation of Fe-Mn-Cr shape memory alloys?

- What is the structure of the electric arc furnace? A Detailed Breakdown of Its Core Components and Design

- What are the advantages and disadvantages of oil as a quenching medium? Achieve Superior Hardening with Minimal Distortion

- Can stainless steel be sintered? A Guide to Manufacturing Complex Parts Efficiently

- Why is precise heating rate control critical in sintering B4C-TiB2 ceramics? Master Structural Integrity

- Is vacuum casting expensive? Discover the Cost-Effective Solution for Low-Volume Production

- What are the 3 stages of annealing? Master the Process to Optimize Metal Properties

- What role does a high-temperature vertical gradient furnace play in the Bridgman method? Master Single Crystal Growth