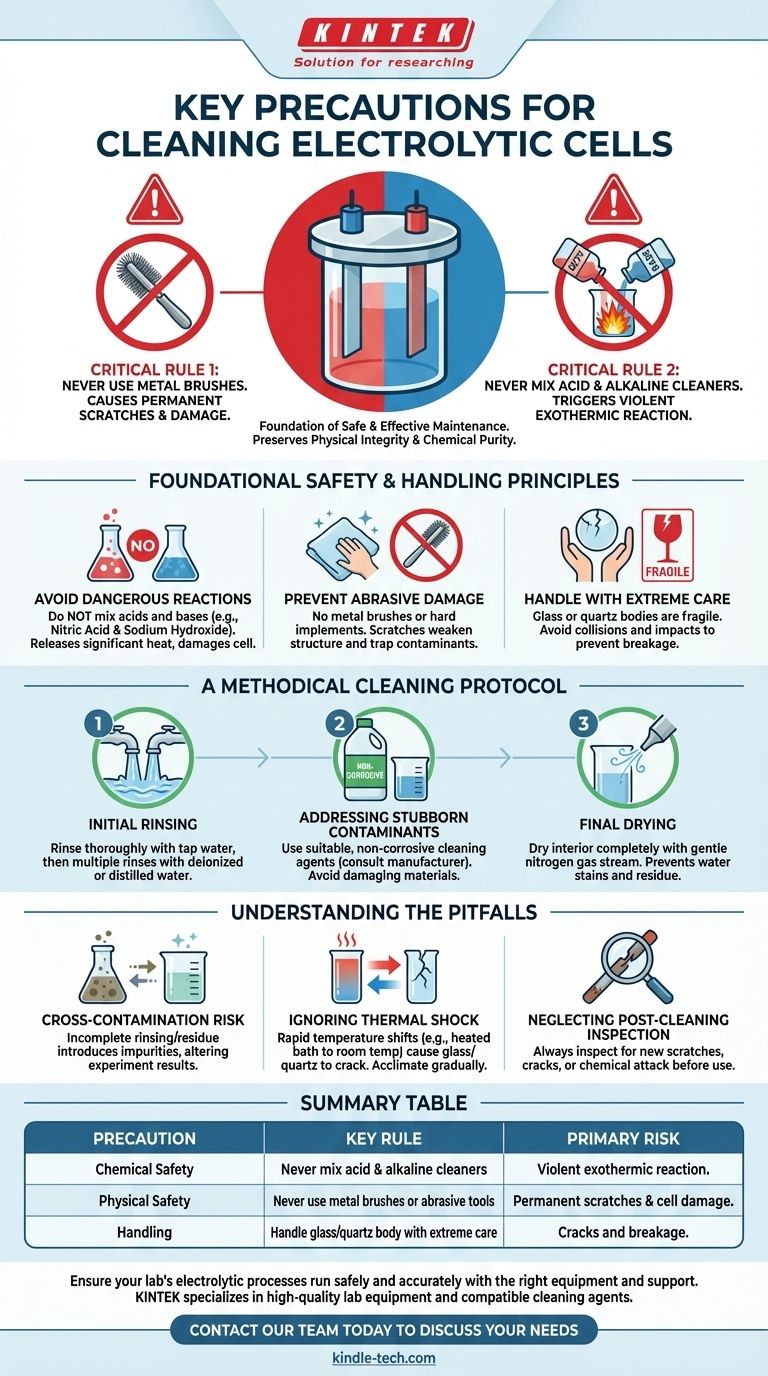

The most critical precautions for cleaning an electrolytic cell are to never use metal brushes, which can permanently scratch the surfaces, and to never mix acid and alkaline cleaning agents, as this can trigger a dangerous exothermic reaction. These two rules form the foundation of safe and effective cell maintenance.

Proper cleaning is not just about removing visible dirt; it's a critical procedure to preserve the cell's physical integrity and chemical purity, ensuring the safety of the operator and the accuracy of future experiments.

Foundational Safety and Handling Principles

Before beginning any cleaning procedure, it's essential to understand the principles that protect both the user and the equipment. Electrolytic cells are sensitive and often fragile instruments.

Avoid Dangerous Chemical Reactions

The single most important chemical safety rule is to never mix acids and bases (like nitric acid and sodium hydroxide) during cleaning. This combination can cause a violent exothermic reaction, releasing a significant amount of heat, which can damage the cell and create a serious safety hazard.

Prevent Abrasive Physical Damage

Never use metal brushes or other hard implements to scrub the cell. The surfaces, whether glass, quartz, or coated electrodes, are easily scratched. These scratches not only weaken the cell's structure but can also trap contaminants that will compromise future experiments.

Handle with Extreme Care

The cell body is typically made of glass or quartz, making it very fragile. Always handle it gently to avoid collisions with hard objects. A small impact can cause cracks or complete breakage, rendering the equipment useless.

A Methodical Cleaning Protocol

A structured approach ensures that the cell is cleaned thoroughly without introducing new problems. Follow these steps after each use.

Step 1: Initial Rinsing

Begin by rinsing all parts thoroughly with standard tap water to remove the bulk of the electrolyte and reagents. Immediately follow this with multiple rinses using deionized or distilled water to remove any remaining ions and impurities.

Step 2: Addressing Stubborn Contaminants

If stubborn dirt or residue remains, use a suitable cleaning agent. Critically, you must select a chemical that is known to be non-corrosive to the specific materials of your cell and electrodes. Always consult the manufacturer's guidelines.

Step 3: Final Drying

The final step is crucial for preventing contamination. Dry the interior of the cell completely, preferably with a gentle stream of nitrogen gas. This method avoids leaving behind water stains or mineral residue that can interfere with subsequent electrochemical measurements.

Understanding the Pitfalls

Even with a good protocol, mistakes can happen. Being aware of common pitfalls helps you avoid them and protect the integrity of your work.

The Risk of Cross-Contamination

The primary goal of cleaning is to prepare the cell for the next experiment. Failing to rinse thoroughly or leaving behind residue from a cleaning agent can introduce impurities that alter your results. Purity is paramount.

Ignoring Thermal Shock

If your process involves temperature changes, such as moving from a heated water bath, be mindful of thermal shock. Rapid, extreme temperature shifts can cause quartz or glass cells to crack. Allow the cell to acclimate to room temperature gradually.

Neglecting Post-Cleaning Inspection

After cleaning and drying, always perform a quick visual inspection. Look for any new scratches, cracks, or signs of chemical attack on the electrodes. Catching damage early can prevent a catastrophic failure during an experiment.

Making the Right Choice for Your Goal

Your cleaning emphasis may shift slightly depending on your primary concern.

- If your primary focus is operator safety: Prioritize the absolute prohibition of mixing acidic and basic cleaning agents.

- If your primary focus is experimental accuracy: Emphasize meticulous rinsing with deionized water and thorough nitrogen drying to eliminate all potential contaminants.

- If your primary focus is equipment longevity: Be most vigilant about gentle handling and the strict avoidance of abrasive tools like metal brushes.

Ultimately, diligent and careful cleaning is a non-negotiable part of rigorous scientific work.

Summary Table:

| Precaution | Key Rule | Primary Risk |

|---|---|---|

| Chemical Safety | Never mix acid and alkaline cleaners | Violent exothermic reaction |

| Physical Safety | Never use metal brushes or abrasive tools | Permanent scratches and cell damage |

| Handling | Handle glass/quartz body with extreme care | Cracks and breakage |

Ensure your lab's electrolytic processes run safely and accurately with the right equipment and support. KINTEK specializes in high-quality lab equipment and consumables, including durable electrolytic cells and compatible cleaning agents. Our experts can help you select the right tools and establish best-practice protocols to protect your investment and your results.

Contact our team today to discuss your specific laboratory needs and enhance your experimental precision.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- H Type Electrolytic Cell Triple Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- What are the proper storage procedures for the multifunctional electrolytic cell? Protect Your Investment and Ensure Data Accuracy

- How should the five-port water bath electrolytic cell be cleaned for maintenance? A Step-by-Step Guide to Reliable Results

- What material is the five-port water bath electrolytic cell made of? High Borosilicate Glass & PTFE Explained

- What are the standard components of the five-port water bath electrolytic cell? Master the Precision Instrument for Electrochemical Analysis

- How should the body of an electrolytic cell be maintained for longevity? Extend Your Equipment's Lifespan