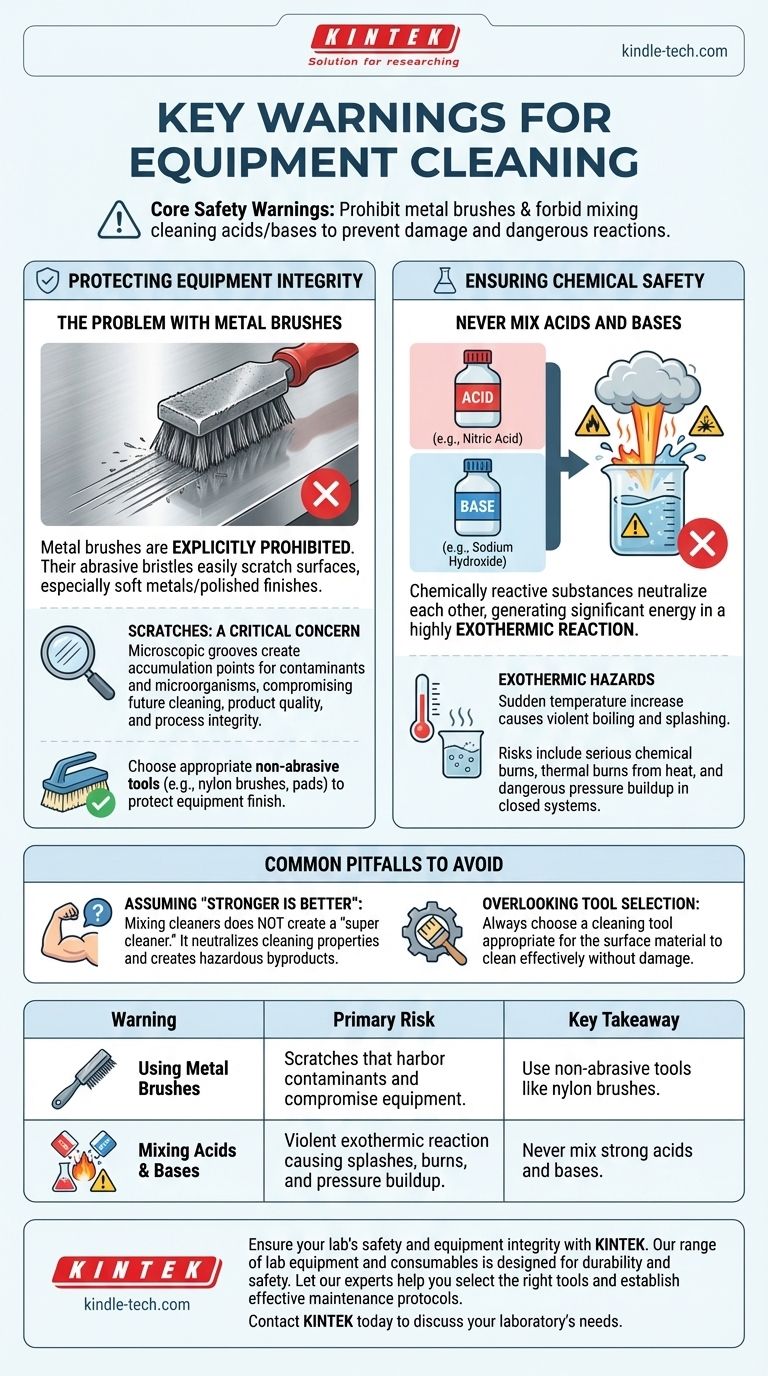

At its core, equipment cleaning safety is governed by two non-negotiable warnings. The first is to prohibit the use of metal brushes to prevent physical damage, and the second is to forbid the mixing of cleaning acids and bases to avoid dangerous chemical reactions.

Understanding these warnings is not just about following rules; it's about protecting the integrity of your equipment and ensuring the fundamental safety of your personnel.

Protecting Equipment Integrity

The physical tools used for cleaning are as important as the chemical agents. Using the wrong tool can cause irreversible damage that compromises the equipment's function and cleanability.

The Problem with Metal Brushes

Metal brushes are explicitly prohibited because their bristles are highly abrasive.

They can easily scratch and gouge the surfaces of the equipment, especially on softer metals or polished finishes.

Why Scratches Are a Critical Concern

Scratches are not merely cosmetic defects. These microscopic grooves create areas where contaminants and microorganisms can accumulate.

This makes the equipment significantly harder to clean and sanitize effectively in the future, potentially compromising product quality or process integrity.

Ensuring Chemical Safety

The interaction between cleaning chemicals is a primary safety concern. Misunderstanding basic chemical principles can lead to hazardous situations.

The Prohibition Against Mixing Acids and Bases

You must never mix cleaning acids (like nitric acid) with cleaning bases (like sodium hydroxide).

These substances are chemically reactive and will neutralize each other in a process that generates significant energy.

Understanding Exothermic Reactions

The reaction between a strong acid and a strong base is highly exothermic, meaning it releases a substantial amount of heat.

This sudden temperature increase can cause the cleaning solution to boil violently and splash out of its container.

The Associated Hazards

The consequences of this reaction are severe. It creates a risk of serious chemical burns from splashing corrosive materials and thermal burns from the intense heat. In a closed system, the rapid release of heat can also lead to a dangerous pressure buildup.

Common Pitfalls to Avoid

Adhering to safety warnings means moving beyond simple memorization to understand the underlying principles and avoid common mistakes.

Assuming "Stronger is Better"

A frequent misconception is that mixing different powerful cleaners will result in a more effective "super cleaner."

In reality, mixing acids and bases neutralizes their cleaning properties and creates hazardous byproducts—heat and salt—instead of improved performance.

Overlooking Tool Selection

Simply avoiding metal brushes is not enough. The broader principle is to always choose a cleaning tool appropriate for the surface material.

Always opt for nylon brushes, pads, or other non-abrasive tools that can clean effectively without damaging the equipment's finish.

A Framework for Safe and Effective Cleaning

Use these principles to guide your cleaning protocol, balancing the need for cleanliness with the imperative for safety and equipment care.

- If your primary focus is equipment longevity: Always prioritize the use of non-abrasive tools to prevent surface damage that can compromise future cleaning.

- If your primary focus is operator safety: Strictly enforce the rule of never mixing acids and bases to prevent violent exothermic reactions and chemical splashes.

Following these core warnings is the foundation of any professional and responsible equipment maintenance program.

Summary Table:

| Warning | Primary Risk | Key Takeaway |

|---|---|---|

| Using Metal Brushes | Scratches that harbor contaminants and compromise equipment. | Use non-abrasive tools like nylon brushes. |

| Mixing Acids & Bases | Violent exothermic reaction causing splashes, burns, and pressure buildup. | Never mix strong acids (e.g., nitric acid) and bases (e.g., sodium hydroxide). |

Ensure your lab's safety and equipment integrity with KINTEK. Proper cleaning is fundamental to reliable results and operator protection. Our range of lab equipment and consumables is designed for durability and safety. Let our experts help you select the right tools and establish effective maintenance protocols. Contact KINTEK today to discuss your laboratory's needs.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Laboratory Hybrid Tissue Grinding Mill

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

People Also Ask

- What are the settings for autoclave sterilization? Ensure Reliable Sterility with Proper Parameters

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- Why is proper maintenance and cleaning of the autoclave important? Ensure Sterilization Efficacy and Safety

- How does an autoclave sterilize instruments supplies and equipment? A Guide to High-Pressure Steam Sterilization

- What is the size of the autoclave? Choose the Right Capacity for Your Lab