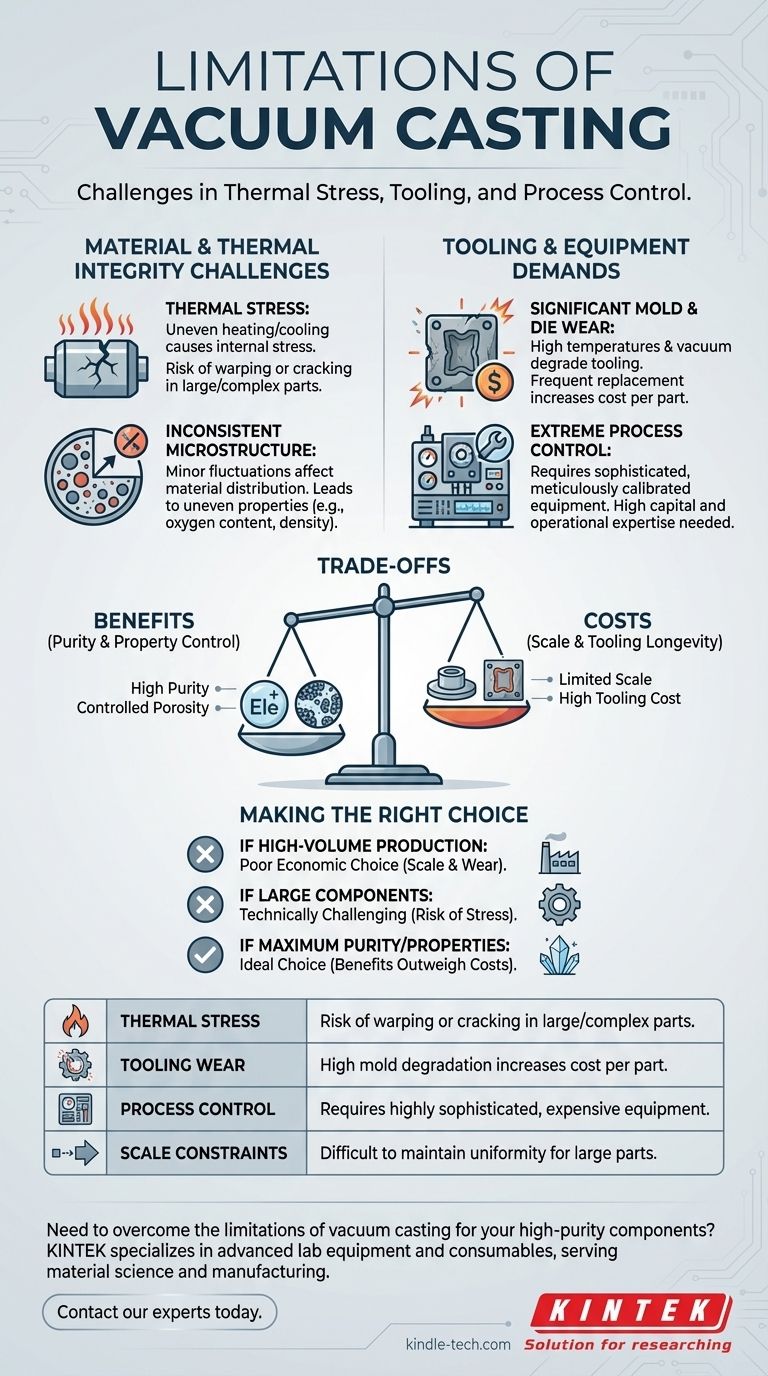

The primary limitations of vacuum casting and similar vacuum-based manufacturing processes center on challenges with thermal stress, tooling degradation, and the stringent need for process control. These factors can introduce inconsistencies in the final product, increase operational costs, and fundamentally limit the size and scale of production.

While vacuum processes offer superior material purity and property control, they do so at the cost of scale and tooling longevity. The core challenge lies in maintaining perfect environmental uniformity, a requirement that becomes exponentially more difficult as the size of the part increases.

The Challenge of Material and Thermal Integrity

The controlled vacuum environment, while beneficial for purity, introduces significant hurdles in maintaining the physical and structural consistency of the part being produced.

The Risk of Thermal Stress

During heating and cooling cycles within a vacuum, temperature gradients can develop across the material. This uneven temperature distribution creates internal stresses.

For large or complex parts, this thermal stress can easily lead to warping or cracking, rendering the component unusable.

Inconsistent Microstructure

The final properties of a material are determined by its internal microstructure. Achieving a perfectly homogenous structure requires exceptionally stable and uniform temperature and pressure.

Even minor fluctuations in these conditions can lead to an uneven distribution of material properties, such as oxygen content or density. This inconsistency can affect the performance and reliability of the final product.

The Demands on Tooling and Equipment

The harsh conditions required for vacuum manufacturing place extreme demands on the molds and machinery used in the process.

Significant Mold and Die Wear

The combination of high temperatures and a vacuum environment can be highly aggressive on tooling. Molds and dies can experience significant wear or even have a chemical reaction with the target material.

This "die loss" means that tooling must be replaced more frequently, which directly increases the cost per part.

The Need for High-Quality Tooling

To withstand these conditions, molds must be made from very high-quality, often expensive, materials. Standard tooling materials would degrade too quickly or contaminate the product.

This requirement adds to the upfront capital investment needed for the process.

Requirement for Extreme Process Control

Maintaining a stable vacuum while precisely managing temperature and pressure fields is a complex engineering challenge.

The equipment must be highly sophisticated and meticulously calibrated. This increases both the initial cost of the machinery and the operational expertise required to run it effectively.

Understanding the Trade-offs

The limitations of vacuum manufacturing are accepted because the process offers unique benefits that are often unattainable through other methods.

Why Use It? Purity and Property Control

The primary advantage of a vacuum environment is the elimination of atmospheric gases that can contaminate or react with the material.

This allows for the creation of high-purity metallic compounds or parts with precisely controlled porosity, which is critical for components in high-performance machinery, plumbing, or bearing systems.

The Inherent Limitation of Scale

The physics of the process work against large-scale production. The larger the part, the harder it is to maintain the uniform temperature and pressure required to prevent thermal stress and ensure a consistent microstructure.

This is why vacuum processes are often best suited for smaller, high-value components rather than large, mass-produced items.

Making the Right Choice for Your Goal

Evaluating these limitations against your project's core requirements is the key to making an informed decision.

- If your primary focus is high-volume mass production: The limitations in scale and high tooling wear make vacuum processes a poor economic choice.

- If your primary focus is creating large components: The risk of thermal stress and cracking makes this process technically challenging and risky for large-scale parts.

- If your primary focus is achieving maximum material purity or specific properties (like porosity): The benefits of the vacuum environment often outweigh the costs and limitations, making it the ideal choice.

Ultimately, vacuum manufacturing is a specialized tool for applications where material integrity and purity are more critical than production speed or component size.

Summary Table:

| Limitation | Key Impact |

|---|---|

| Thermal Stress | Risk of warping or cracking in large/complex parts |

| Tooling Wear | High mold degradation increases cost per part |

| Process Control | Requires sophisticated, expensive equipment |

| Scale Constraints | Difficult to maintain uniformity for large parts |

Need to overcome the limitations of vacuum casting for your high-purity components? KINTEK specializes in advanced lab equipment and consumables, serving the precise needs of laboratories in material science and manufacturing. Our expertise can help you navigate the trade-offs between purity, scale, and cost. Contact our experts today to discuss the right solution for your project's unique requirements and ensure optimal material integrity.

Visual Guide

Related Products

- Touchscreen Automatic Vacuum Heat Press

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- How does the high-temperature and high-pressure environment provided by vacuum hot press equipment improve the interfacial bonding between Mo fibers and the TiAl matrix?

- What is the function of a vacuum-sealed, heated stainless steel container? Ensuring Integrity in LBE Corrosion Tests

- How does a laboratory vacuum hot-pressing furnace achieve the densification of ZrB2-SiC through synergistic control?

- How does the pressure control system of vacuum hot press equipment contribute to preventing material defects? Learn More

- Why is a laboratory hot press required after the spray-coating of polymer-ceramic composite electrolytes? Essential density.