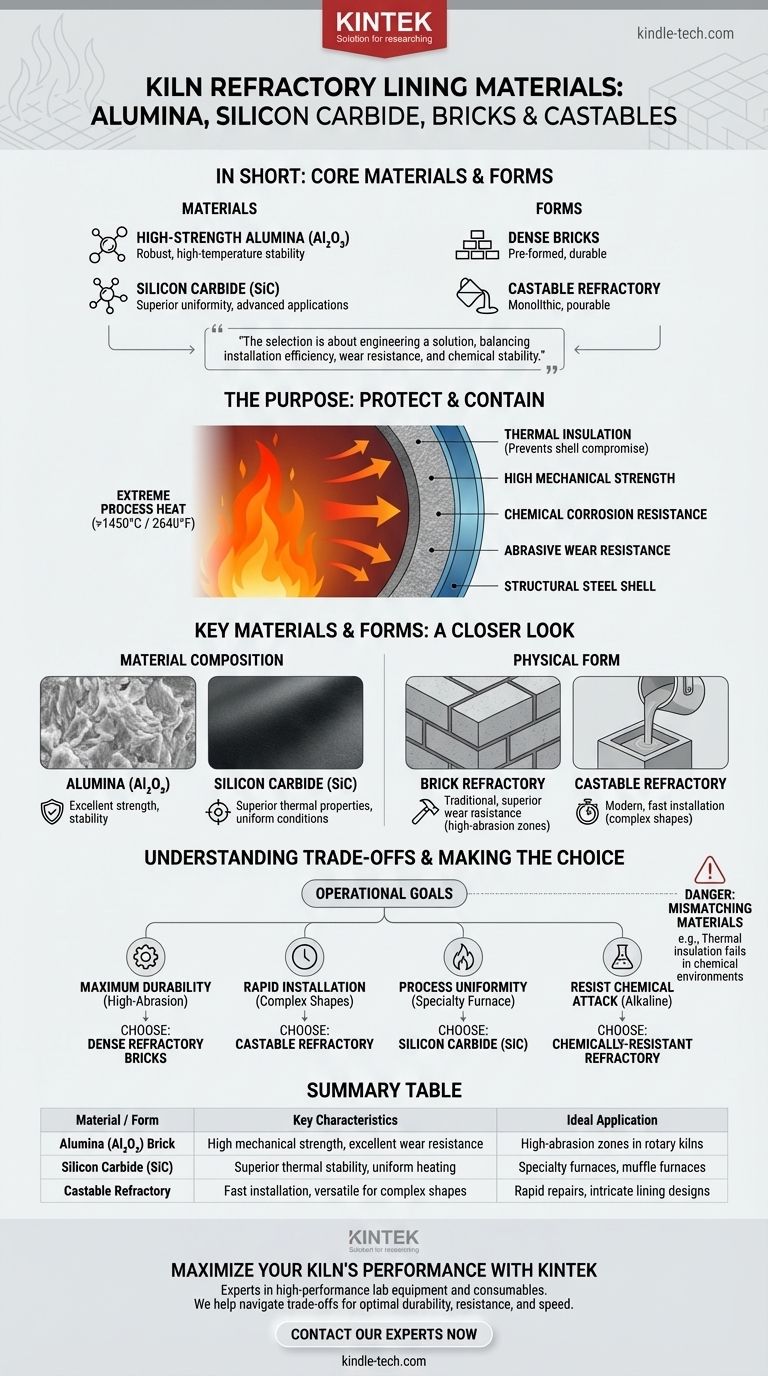

In short, kiln refractory linings are primarily made from high-performance ceramics like high-strength alumina (Al₂O₃) and silicon carbide (SiC). These materials are supplied in two main forms: dense, pre-formed bricks or a monolithic, pourable material known as castable refractory. The final choice depends entirely on the specific thermal, chemical, and mechanical demands of the kiln's operational environment.

The selection of a refractory material is not about finding a single "best" material, but about engineering a solution. The choice between alumina or silicon carbide, in brick or castable form, is a critical trade-off between installation efficiency, wear resistance, and chemical stability for a specific industrial process.

The Purpose of a Refractory Lining

A kiln's refractory lining is the critical interface between the extreme process heat and the structural steel shell. Its primary job is to contain heat and protect the equipment from thermal, chemical, and mechanical damage.

Protecting the Kiln's Structure

The most fundamental role of the lining is thermal insulation. It prevents the high internal temperatures, which can exceed 1450°C (2640°F) in applications like cement production, from compromising the structural integrity of the kiln's outer shell.

Resisting the Process Environment

The lining must endure a hostile environment. This requires materials with a specific set of properties, including high mechanical strength, resistance to chemical corrosion, and the ability to withstand abrasive wear from the materials being processed.

Key Materials and Forms

The materials and the form they take are chosen to meet the specific demands of the kiln. The most common options are based on alumina and silicon carbide, delivered as either brick or a castable mixture.

Material Composition: Alumina vs. Silicon Carbide

High-strength alumina (Al₂O₃) is a robust and widely used refractory material. It provides excellent strength and stability at high temperatures, making it a reliable choice for many applications.

Silicon carbide (SiC) is considered a more advanced material. Its superior properties help ensure highly accurate and uniform process conditions, which is critical in specialized applications like muffle furnaces.

Physical Form: Brick vs. Castable

Brick refractory is the traditional solution. These pre-fired bricks are exceptionally durable and offer superior wear resistance, making them ideal for zones where the kiln processes highly abrasive materials.

Castable refractory is a more modern, versatile alternative. It is a dry material mixed with water and then poured or gunned into place, similar to concrete. This makes installation significantly faster and easier than laying individual bricks.

Understanding the Trade-offs

Choosing the right refractory is an exercise in balancing competing priorities. No single solution is perfect for every part of a kiln or every type of process.

Installation Speed vs. Wear Resistance

The most significant trade-off is between castable and brick linings.

Castable refractories offer faster and less labor-intensive installation. However, for a similar chemical composition, they may not offer the same level of wear resistance as a dense, pre-fired brick.

Brick refractories, while more labor-intensive to install, provide maximum density and abrasion resistance. They are the preferred choice for high-wear zones in rotary kilns handling abrasive materials.

The Danger of Mismatching Materials

Refractory materials are not interchangeable. A material designed for thermal insulation may fail catastrophically in a chemically aggressive environment.

For example, standard thermal insulation bricks and refractory fiber cannot be used in environments with high-temperature chemical erosion, such as a cement rotary kiln. The alkaline environment would rapidly degrade these materials, leading to lining failure.

Making the Right Choice for Your Application

Your selection must be guided by a clear understanding of your kiln's operating conditions and your primary operational goals.

- If your primary focus is maximum durability in a high-abrasion zone: Dense refractory bricks are the most reliable choice.

- If your primary focus is rapid installation or lining a complex shape: Castable refractory offers significant advantages in time and labor.

- If your primary focus is process uniformity and control in a specialty furnace: Advanced materials like silicon carbide (SiC) provide the necessary stability.

- If your primary focus is resisting chemical attack from alkaline materials: You must select a specific, chemically-resistant refractory and avoid standard insulation materials.

Ultimately, selecting the correct refractory lining is a foundational decision that directly impacts your kiln's efficiency, lifespan, and operational safety.

Summary Table:

| Material / Form | Key Characteristics | Ideal Application |

|---|---|---|

| Alumina (Al₂O₃) Brick | High mechanical strength, excellent wear resistance | High-abrasion zones in rotary kilns |

| Silicon Carbide (SiC) | Superior thermal stability, uniform heating | Specialty furnaces, muffle furnaces |

| Castable Refractory | Fast installation, versatile for complex shapes | Rapid repairs, intricate lining designs |

Maximize your kiln's performance and lifespan with the right refractory solution.

Choosing the correct lining is critical for operational efficiency and safety. The experts at KINTEK specialize in high-performance lab equipment and consumables, including refractory materials for demanding laboratory and industrial kilns. We can help you navigate the trade-offs between alumina and silicon carbide, brick and castable forms, to find the optimal balance of durability, chemical resistance, and installation speed for your specific process.

Contact us today to discuss your kiln's requirements and get a tailored recommendation. Let KINTEK be your partner in achieving superior thermal processing results.

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

People Also Ask

- What is the resistivity of silicon carbide? It's a tunable property from <0.1 ohm-cm to highly resistive.

- What is the temperature resistance of silicon carbide? Withstands Extreme Heat Up to 1500°C

- Is silicon carbide better than ceramic? Discover the Superior Technical Ceramic for Your Application

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance