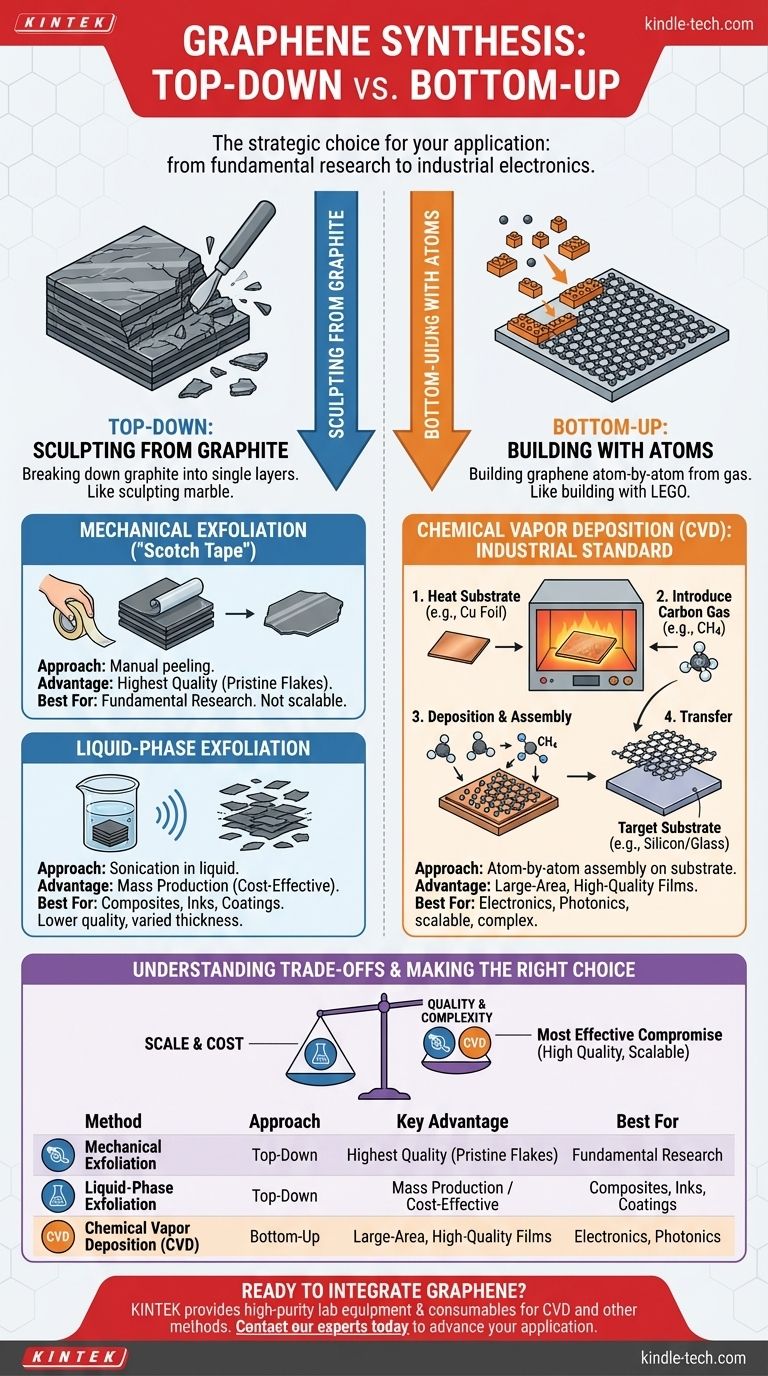

In essence, graphene is synthesized using two opposing strategies: "top-down" methods that break down graphite into single layers, and "bottom-up" methods that build graphene atom-by-atom. The most prominent top-down approaches are mechanical and liquid-phase exfoliation, while the leading bottom-up method, and the most promising for industrial scale, is Chemical Vapor Deposition (CVD).

The method used to create graphene is not a matter of preference but a strategic choice dictated by the final application. While simple exfoliation is perfect for fundamental research, only methods like Chemical Vapor Deposition (CVD) can produce the large, high-quality sheets required for advanced electronics.

The Two Fundamental Approaches: Top-Down vs. Bottom-Up

To understand graphene synthesis, it's best to start with the two core philosophies. Each approach has distinct advantages and is suited for different outcomes.

Top-Down: Sculpting from Graphite

Top-down methods begin with graphite—a three-dimensional stack of graphene layers—and use force to separate it. This is conceptually similar to sculpting from a block of marble.

These techniques are effective for producing graphene flakes, but controlling the exact number of layers can be challenging.

Bottom-Up: Building with Atoms

Bottom-up methods start with a carbon-containing gas and assemble a graphene sheet one atom at a time on a substrate. This is like building a structure with individual LEGO bricks.

This approach offers superior control over the structure and quality of the final graphene sheet, making it ideal for high-performance applications.

Top-Down Methods: Deriving Graphene from Graphite

These methods leverage the weak bonds between graphene layers in graphite to isolate them.

Mechanical Exfoliation (The "Scotch Tape" Method)

This is the original method used to discover graphene. It involves using adhesive tape to repeatedly peel layers from a piece of graphite until a single, pristine layer is isolated.

While it produces extremely high-quality graphene flakes, it is a manual process that is not scalable for mass production. Its primary use is in fundamental scientific research.

Liquid-Phase Exfoliation

In this method, graphite is suspended in a liquid and subjected to high energy, such as sonication, to shear the layers apart.

This technique is suitable for mass-producing graphene flakes for use in composites, inks, and coatings. However, the resulting material typically has lower electrical quality and consists of flakes with varying thicknesses.

Bottom-Up Methods: Building Graphene Atom by Atom

Bottom-up synthesis is the key to creating large, uniform graphene films suitable for the electronics industry.

Chemical Vapor Deposition (CVD): The Industrial Standard

CVD is widely regarded as the most promising technique for producing high-quality graphene over large areas. It is the leading method for applications in electronics and photonics.

How CVD Works

The process involves heating a substrate, typically a copper (Cu) foil, inside a furnace. A carbon-containing gas, like methane (CH4), is then introduced.

At high temperatures, the methane decomposes, and carbon atoms deposit onto the surface of the copper foil, self-assembling into a continuous, single layer of graphene. The graphene film is then carefully transferred to a target substrate (like silicon or glass) for use in a device.

Optimizing CVD for Superior Quality

The quality of CVD graphene depends on precise control over synthesis parameters like temperature, gas flow, and the nature of the substrate.

Researchers use techniques like partial growth studies—stopping the process before a full film forms—to analyze how graphene crystals nucleate and grow. This insight helps them minimize defects and create larger, more perfect crystals. Advanced variations, like the vapor-trapping method, are designed to synthesize very large, single-crystalline graphene domains.

Understanding the Trade-offs

No single synthesis method is perfect. The choice always involves a compromise between scale, quality, and cost.

Scale vs. Quality

This is the central trade-off. Mechanical exfoliation offers a perfect crystal structure but is impossible to scale. Liquid-phase exfoliation offers immense scale but produces lower-quality, inconsistent flakes.

CVD represents the most effective compromise, enabling the growth of high-quality, large-area films with a process that can be industrialized.

Cost and Complexity

Mechanical exfoliation is simple and cheap for a lab but has no industrial relevance. Liquid-phase exfoliation is relatively cost-effective for bulk materials.

CVD, on the other hand, requires significant investment in specialized equipment like high-temperature furnaces and vacuum systems. The subsequent transfer process also adds a layer of complexity and potential for damage. Other methods, like the sublimation of silicon carbide, produce high-quality graphene but are often prohibitively expensive.

Making the Right Choice for Your Goal

Your intended application dictates the correct synthesis method.

- If your primary focus is fundamental research: Mechanical exfoliation remains the best source for pristine, high-quality flakes for lab-scale experiments.

- If your primary focus is large-scale electronics: Chemical Vapor Deposition (CVD) is the most viable path to producing the large, uniform, and high-quality graphene films required for devices.

- If your primary focus is bulk production for composites or inks: Liquid-phase exfoliation offers the most cost-effective route for mass-producing graphene flakes, accepting a trade-off in electrical quality and structural perfection.

Understanding these distinct pathways is the first step in harnessing graphene's potential for your specific application.

Summary Table:

| Method | Approach | Key Advantage | Best For |

|---|---|---|---|

| Mechanical Exfoliation | Top-Down | Highest Quality (Pristine Flakes) | Fundamental Research |

| Liquid-Phase Exfoliation | Top-Down | Mass Production / Cost-Effective | Composites, Inks, Coatings |

| Chemical Vapor Deposition (CVD) | Bottom-Up | Large-Area, High-Quality Films | Electronics, Photonics |

Ready to Integrate Graphene into Your Research or Product?

Choosing the right synthesis method is critical to the success of your project. The experts at KINTEK understand the nuances of each technique. We provide the high-purity lab equipment and consumables—including substrates and carbon sources for CVD—that researchers and industries rely on to produce high-quality graphene.

Let us help you achieve your goals. Whether you are scaling up for electronics or optimizing for composite materials, our team can support your specific laboratory needs.

Contact our experts today to discuss how KINTEK's solutions can advance your graphene application.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance