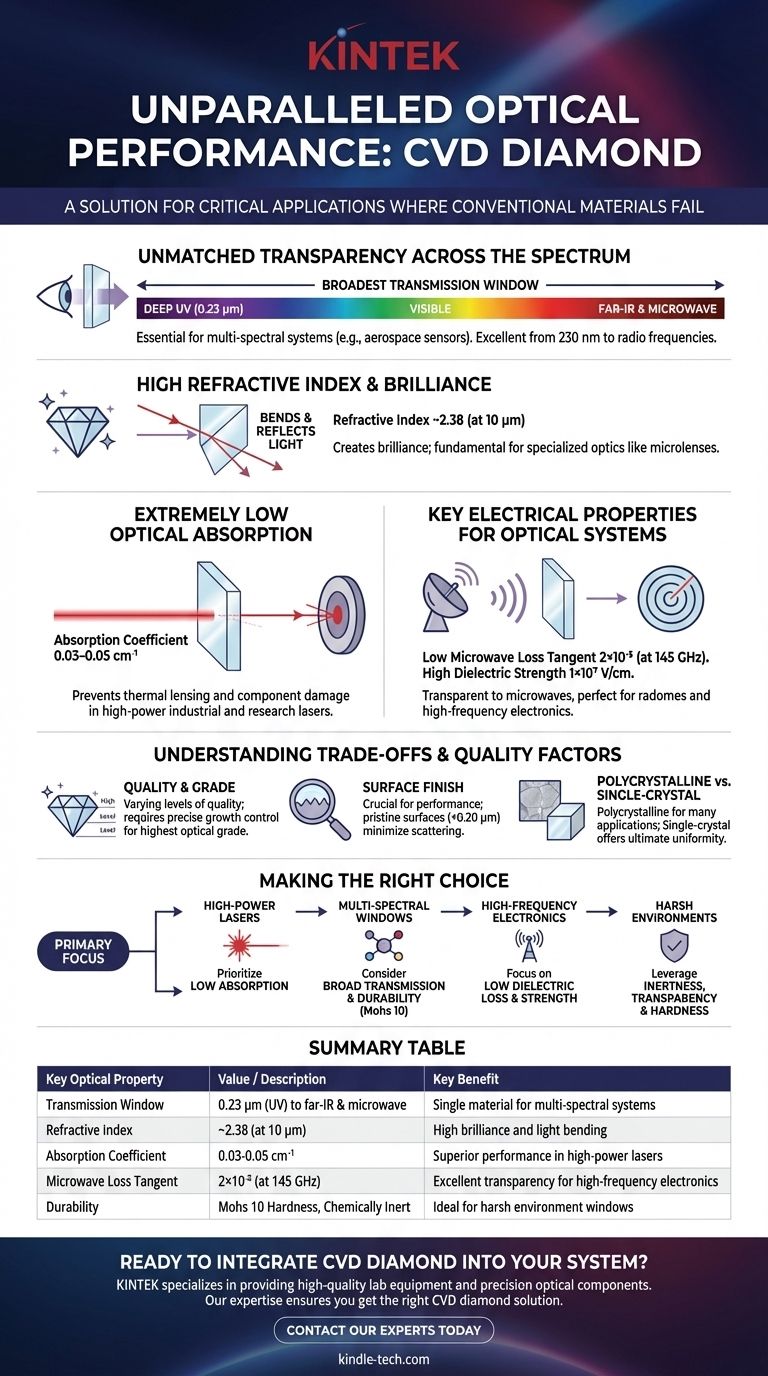

In short, Chemical Vapor Deposition (CVD) diamond possesses a suite of exceptional optical properties, most notably its extremely broad transparency from deep ultraviolet (0.23 µm) through the visible spectrum and into the far-infrared and microwave regions. Key metrics include a high refractive index of 2.376 (at 10 μm), a very low absorption coefficient of 0.03-0.05 cm⁻¹, and a low microwave loss tangent, making it functionally identical to high-quality natural diamond for technical applications.

The core takeaway is that CVD diamond is not just another transparent material. Its unique combination of unparalleled optical bandwidth, extreme durability, and excellent thermal properties makes it a solution for performance-critical applications where conventional optical materials like glass or sapphire would fail.

Deconstructing the Optical Excellence of CVD Diamond

To understand the value of CVD diamond, we must look at its individual properties and the problems they solve. From a physical and chemical standpoint, the diamond produced via CVD is real diamond, sharing the same internal sp³-bonded carbon structure as its mined counterpart.

Unmatched Transparency Across the Spectrum

The single most important optical property of CVD diamond is its incredibly wide transmission window. It remains highly transparent from the deep UV (starting at 230 nm) all the way to radio and microwave frequencies.

This makes it an ideal material for windows and lenses in systems that must operate across multiple spectral bands, such as in advanced military and aerospace sensors.

High Refractive Index and Brilliance

CVD diamond has a refractive index of approximately 2.38. This high value is responsible for the "brilliance" and "sparkle" associated with gemstone diamonds, as it powerfully bends and reflects light.

While less critical for many technical optics, this property is fundamental to the material's identity and is leveraged in specialized applications like microlenses.

Extremely Low Optical Absorption

For high-power applications, particularly with lasers, absorption is the enemy. Absorbed light turns into heat, which can cause the optical component to expand, deform (thermal lensing), or even fracture.

CVD diamond's absorption coefficient is remarkably low (0.03-0.05 cm⁻¹). This allows it to be used as windows for high-power industrial and research lasers where other materials would quickly fail from thermal runaway.

Key Electrical Properties for Optical Systems

In applications involving high frequencies, such as microwave or radar windows, certain electrical properties are paramount.

CVD diamond shines here with a low loss tangent (2×10⁻⁵ at 145 GHz) and high dielectric strength (1×10⁷ V/cm). This means it is transparent to microwaves and can withstand intense electric fields without breaking down, making it perfect for radomes and high-power electronic components.

Understanding the Trade-offs and Quality Factors

While CVD diamond offers superior performance, selecting the right material is not as simple as choosing "diamond." The quality and grade of the material are critical and must be matched to the application.

Not All CVD Diamond is Created Equal

The CVD growth process is highly controlled but can produce material with varying levels of quality. Some as-grown diamond may have a brownish tint or internal impurities that must be removed through post-processing treatments.

Achieving the highest "optical grade" with minimal absorption and scattering requires precise control over the growth chemistry and may involve selecting specific crystals from a larger batch.

The Importance of Surface Finish

Optical performance is directly tied to surface quality. Any roughness or imperfection will scatter light, which is particularly detrimental for shorter wavelengths like UV and visible light.

CVD diamond is available in different grades, with specified surface roughness ranging from over 1 µm for rougher applications down to 0.20 µm or less for polished "finishing" quality optics. A pristine, super-polished surface is non-negotiable for high-resolution imaging or laser systems.

Polycrystalline vs. Single-Crystal

CVD diamond can be produced as a large sheet of many small, interconnected crystals (polycrystalline) or as a single, flawless crystal.

Polycrystalline diamond is excellent for many applications like windows and heat spreaders. However, for the most demanding optical applications, the tiny boundaries between the crystals can cause a minute amount of scattering. Single-crystal diamond eliminates this variable entirely, offering the ultimate in optical uniformity.

Making the Right Choice for Your Application

Selecting the correct grade of CVD diamond is a matter of aligning the material's strengths with your primary engineering goal.

- If your primary focus is high-power laser systems: Prioritize a grade with the lowest certified optical absorption coefficient to prevent thermal lensing and component damage.

- If your primary focus is multi-spectral windows (defense/aerospace): The key property is the broad transmission range, but you must also consider the extreme hardness (Mohs 10) for durability against abrasion.

- If your primary focus is high-frequency electronics (microwave windows): The low dielectric loss tangent and high dielectric strength are the most critical parameters to ensure signal integrity and power handling.

- If your primary focus is durability in harsh environments: The combination of chemical inertness, optical transparency, and extreme hardness is what makes CVD diamond uniquely suitable for protective windows.

Ultimately, leveraging CVD diamond successfully means treating it not as a commodity but as a high-performance engineered material specified for a precise task.

Summary Table:

| Key Optical Property | Value / Description | Key Benefit |

|---|---|---|

| Transmission Window | 0.23 µm (UV) to far-IR & microwave | Single material for multi-spectral systems |

| Refractive Index | ~2.38 (at 10 µm) | High brilliance and light bending |

| Absorption Coefficient | 0.03-0.05 cm⁻¹ | Superior performance in high-power laser applications |

| Microwave Loss Tangent | 2×10⁻⁵ (at 145 GHz) | Excellent transparency for high-frequency electronics |

| Durability | Mohs 10 Hardness, Chemically Inert | Ideal for harsh environment and protective windows |

Ready to integrate the unparalleled optical performance of CVD diamond into your system?

KINTEK specializes in providing high-quality lab equipment and consumables, including precision optical components. Whether your application requires the broadest transmission window for aerospace sensors, the lowest absorption for high-power lasers, or extreme durability for harsh environments, our expertise ensures you get the right CVD diamond solution.

Contact our experts today to discuss how CVD diamond can solve your most demanding optical challenges and enhance your project's performance.

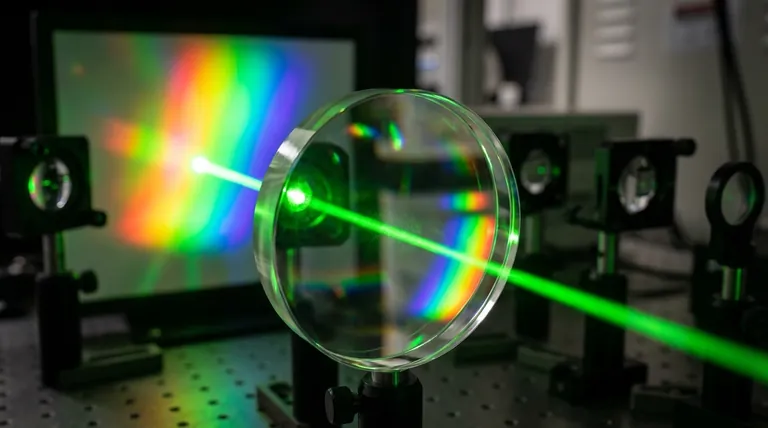

Visual Guide

Related Products

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Optical Windows for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the methods of coating thin films? Choose the Right PVD or CVD Process for Your Application

- What are the advantages of thin film over thick film? Achieve Unmatched Precision and Stability

- What is the target sputtering deposition? A Guide to Precision Thin-Film Coating

- What are the characteristics of a coating produced by low-temperature arc vapor deposition (LTAVD)? Key Performance Insights

- What is the difference between PCD and CVD? Choosing the Right Diamond Solution for Your Tools

- What are some key film characteristics to consider? Optimize Your Thin Film Deposition for Peak Performance

- What is a thin film semiconductor? Unlock Flexible, Large-Area Electronics

- Which of the following are properties of carbon nanotubes? Unlock Their Unique Electrical, Thermal & Mechanical Strengths