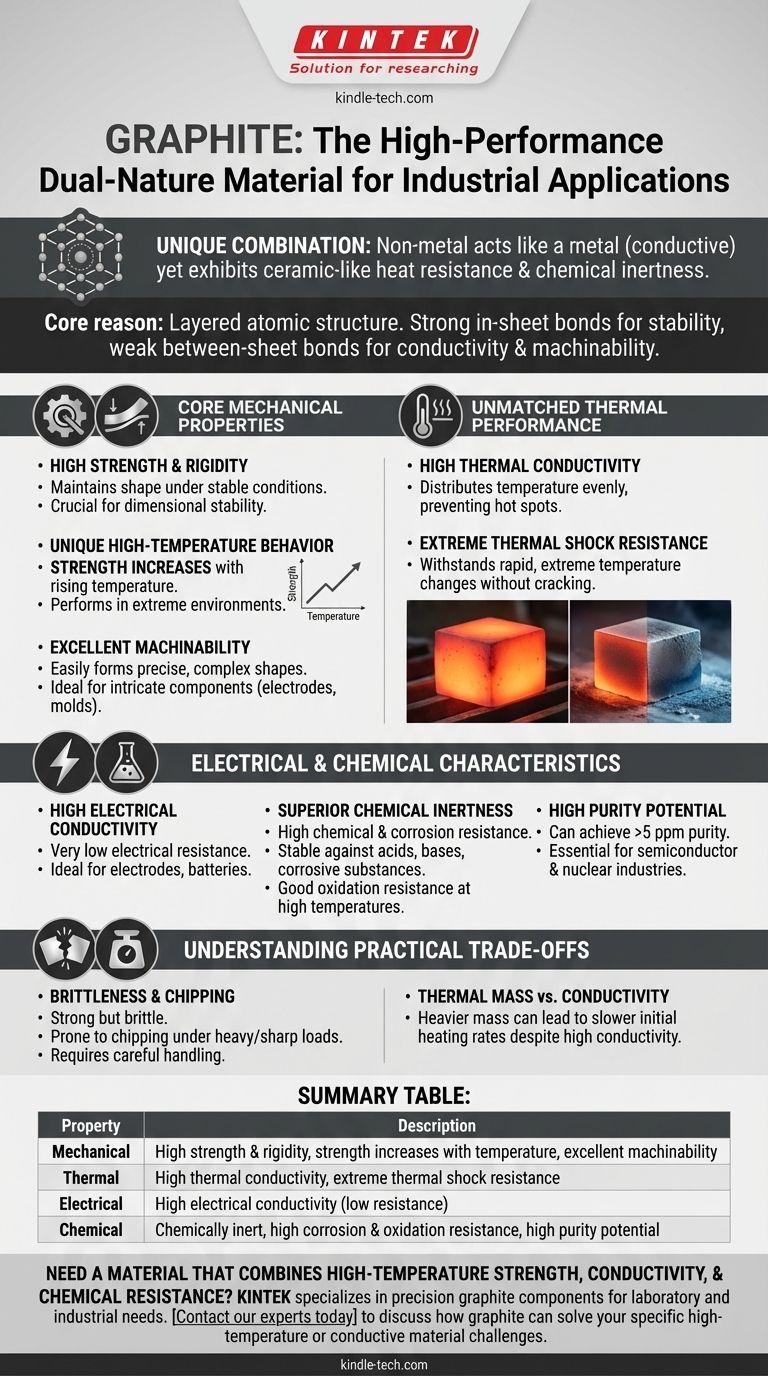

In short, graphite possesses a unique combination of physical and chemical properties that often appear contradictory. It is a non-metal that acts like a metal in its high electrical and thermal conductivity, while also exhibiting the high-temperature resistance and chemical inertness of a ceramic. This duality makes it an indispensable material in many demanding industrial applications.

The core reason for graphite's versatile properties is its layered atomic structure. Strong bonds within its carbon sheets provide immense strength and stability, while weaker bonds between the sheets allow for conductivity and ease of machining.

Core Mechanical Properties

The mechanical behavior of graphite is one of its most defining features, particularly its performance under thermal stress.

High Strength and Rigidity

Graphite is a very rigid material that maintains its shape almost indefinitely under stable conditions. This structural integrity is crucial for applications like furnace hearths and supports where dimensional stability is paramount.

Unique High-Temperature Behavior

Unlike most materials that weaken as they heat up, graphite’s strength actually increases with rising temperature. This remarkable property allows it to perform reliably in environments far too extreme for most metals.

Excellent Machinability

Despite its strength, graphite is relatively easy to machine into precise and complex shapes. This allows for the creation of intricate components like electrodes or molds with high dimensional accuracy.

Unmatched Thermal Performance

Graphite's ability to manage heat is exceptional, making it a first-choice material for high-temperature processes.

High Thermal Conductivity

Graphite conducts heat very well. This property helps to distribute temperature evenly and minimize thermal gradients, which is critical for preventing hot spots in furnace applications.

Extreme Thermal Shock Resistance

Its high thermal conductivity, combined with low thermal expansion, gives graphite excellent resistance to thermal shock. It can withstand rapid and extreme temperature changes without cracking or failing, a common point of failure for many ceramics.

Electrical and Chemical Characteristics

Graphite's electrical conductivity and chemical stability are foundational to its use in electrical and corrosive environments.

High Electrical Conductivity

As a result of its atomic structure, graphite is an excellent electrical conductor, with very low electrical resistance. This makes it ideal for use as electrodes in electric arc furnaces and batteries.

Superior Chemical Inertness

Graphite exhibits high chemical resistance and good corrosion resistance. It is stable when exposed to most acids, bases, and corrosive substances, making it suitable for handling harsh chemicals. It also has good oxidation resistance at high temperatures.

High Purity Potential

Graphite, particularly isostatic graphite, can be produced with an extremely high level of purity, often with impurity levels below 5 parts per million (ppm). This is critical for the semiconductor and nuclear industries where contamination must be avoided.

Understanding the Practical Trade-offs

While its properties are impressive, it's important to understand the practical limitations of working with graphite.

Brittleness and Chipping

Graphite is strong but also brittle. Components like furnace hearth rails can be prone to chipping during the loading and unloading of heavy or sharp materials. This requires careful handling procedures.

Thermal Mass vs. Conductivity

Although graphite’s high thermal conductivity helps minimize this effect, its heavier mass can result in slower initial heating rates compared to lighter materials. The system must absorb more energy to reach the target temperature.

How to Apply This to Your Project

Choosing graphite depends on leveraging its unique strengths for a specific industrial challenge.

- If your primary focus is high-temperature structural integrity: Graphite's ability to gain strength as it heats makes it superior to almost any metal for furnace components and crucibles.

- If your primary focus is electrical or thermal transfer: Its low electrical resistance and high thermal conductivity make it the ideal choice for electrodes, heat exchangers, and heat sinks in extreme environments.

- If your primary focus is precision and purity: Graphite's excellent machinability and potential for high purity are critical for producing components for the semiconductor, glass, and electronics industries.

Ultimately, graphite's distinct blend of properties makes it a powerful problem-solving material for the most demanding engineering challenges.

Summary Table:

| Property | Description |

|---|---|

| Mechanical | High strength & rigidity, strength increases with temperature, excellent machinability |

| Thermal | High thermal conductivity, extreme thermal shock resistance |

| Electrical | High electrical conductivity (low resistance) |

| Chemical | Chemically inert, high corrosion & oxidation resistance, high purity potential |

Need a material that combines high-temperature strength, conductivity, and chemical resistance?

Graphite's unique properties make it ideal for demanding applications like furnace components, electrodes, and semiconductor parts. KINTEK specializes in high-quality lab equipment and consumables, including precision graphite components for laboratory and industrial needs.

Contact our experts today to discuss how graphite can solve your specific high-temperature or conductive material challenges.

Visual Guide

Related Products

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the factors affecting sample size requirements? Master the Trade-Offs for Credible Research

- What are the applications of biomass? A Guide to Its Versatile Renewable Energy Uses

- How is a laboratory oven utilized in NZSP solid electrolyte processing? Master Precise Solvent Removal for Research

- What materials can be applied using sputtering and what forms can the coatings take? Versatile Coating Solutions

- What property does KBr have that makes it suitable for the infrared region? Unlock Clear IR Spectroscopy Analysis

- What is the physical sputtering method? A Guide to High-Performance Thin Film Deposition

- What are the properties of the graphite? Unlock High-Temperature Strength & Conductivity

- What are the advantages of microwave heating for HEA catalysts? Unlock Superior OER Efficiency with Rapid Sintering