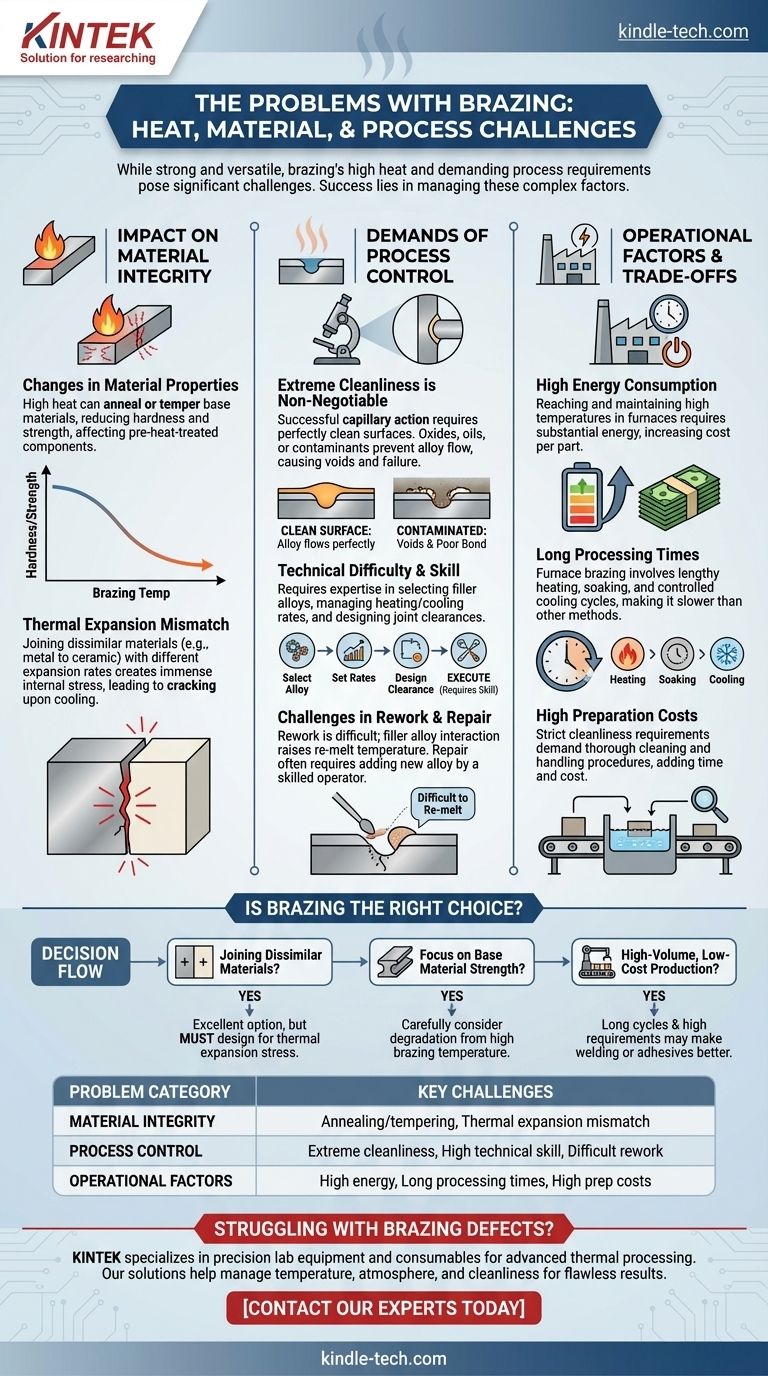

While an exceptionally strong and versatile joining method, the primary problems with brazing center on its high heat, which can negatively alter the base materials, and its demanding process requirements, which necessitate extreme cleanliness and technical skill to avoid defects. Further challenges arise when joining dissimilar materials due to differences in thermal expansion.

The core challenge of brazing is not the strength of the finished joint, but managing the complex interplay between heat, materials, and process control. Success depends on accommodating these factors in your design and execution.

The Impact on Base Material Integrity

The high temperatures required for brazing, while lower than welding, are still significant enough to fundamentally change the parts you are joining. This is a critical consideration in any engineering application.

Changes in Material Properties

The heat required to melt the brazing alloy can anneal or temper the base materials, reducing their hardness and strength. This is a significant drawback if the components rely on prior heat treatment for their mechanical properties.

Thermal Expansion Mismatch

When joining dissimilar materials, such as a ceramic to a metal, each material expands and contracts at a different rate when heated and cooled. This differential expansion creates immense internal stress that can crack the weaker material or compromise the joint upon cooling.

The Demands of Process Control

Brazing is not a forgiving process. Unlike mechanical fastening, it requires meticulous preparation and execution to achieve a sound, reliable joint.

Extreme Cleanliness is Non-Negotiable

Brazing relies on capillary action to draw the molten filler metal into the joint. This phenomenon only works on perfectly clean surfaces. Any oxides, oils, or contaminants will prevent the alloy from flowing and bonding, resulting in voids and a failed joint.

Technical Difficulty and Skill

Proper brazing requires a high degree of technical understanding. Choosing the correct filler alloy, managing the heating and cooling rates, and designing the joint with the proper clearance are all critical variables that demand expertise.

Challenges in Rework and Repair

If a brazed joint has a defect, it cannot simply be re-melted into place. During the initial process, the filler alloy interacts with the base metals, often raising its re-melt temperature. A successful repair typically requires adding a small amount of new alloy to the defective area, a task that demands a skilled operator.

Understanding the Trade-offs

Beyond the technical challenges, brazing involves significant operational considerations that can make it more complex or costly than alternative methods.

High Energy Consumption

Reaching and maintaining brazing temperatures, often in a vacuum or controlled-atmosphere furnace, requires a substantial amount of energy. This directly impacts the cost per part.

Long Processing Times

Furnace brazing, a common method for high-quality joints, involves lengthy cycles for heating, soaking at temperature, and controlled cooling. This makes it a slower process compared to many welding or mechanical assembly techniques.

High Preparation Costs

The strict requirement for cleanliness means parts must undergo thorough cleaning and handling procedures before entering the brazing process, adding both time and cost to the manufacturing workflow.

Is Brazing the Right Choice for Your Application?

To decide if brazing is the correct approach, weigh its challenges against your primary engineering goal.

- If your primary focus is joining dissimilar materials (like metal to ceramic): Brazing is an excellent option, but you must design the joint to accommodate or mitigate the stress from thermal expansion mismatch.

- If your primary focus is maintaining the base material's strength: You must carefully consider if the required brazing temperature will unacceptably degrade the material's heat-treated properties.

- If your primary focus is high-volume, low-cost production: The long cycle times and high process requirements of brazing may make other methods, like welding or adhesives, more suitable.

Ultimately, brazing's limitations are manageable when they are understood and planned for from the outset.

Summary Table:

| Problem Category | Key Challenges |

|---|---|

| Material Integrity | Annealing/tempering of base metals, thermal expansion mismatch in dissimilar materials |

| Process Control | Extreme cleanliness requirements, high technical skill, difficult rework/repair |

| Operational Factors | High energy consumption, long processing times, high preparation costs |

Struggling with brazing defects or process control? KINTEK specializes in precision lab equipment and consumables for advanced thermal processing. Our solutions help you manage the critical variables of temperature, atmosphere, and cleanliness for flawless brazing results. Contact our experts today to discuss how we can enhance your brazing reliability and efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- Can you braze two different metals? Yes, and here’s how to do it successfully.

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer