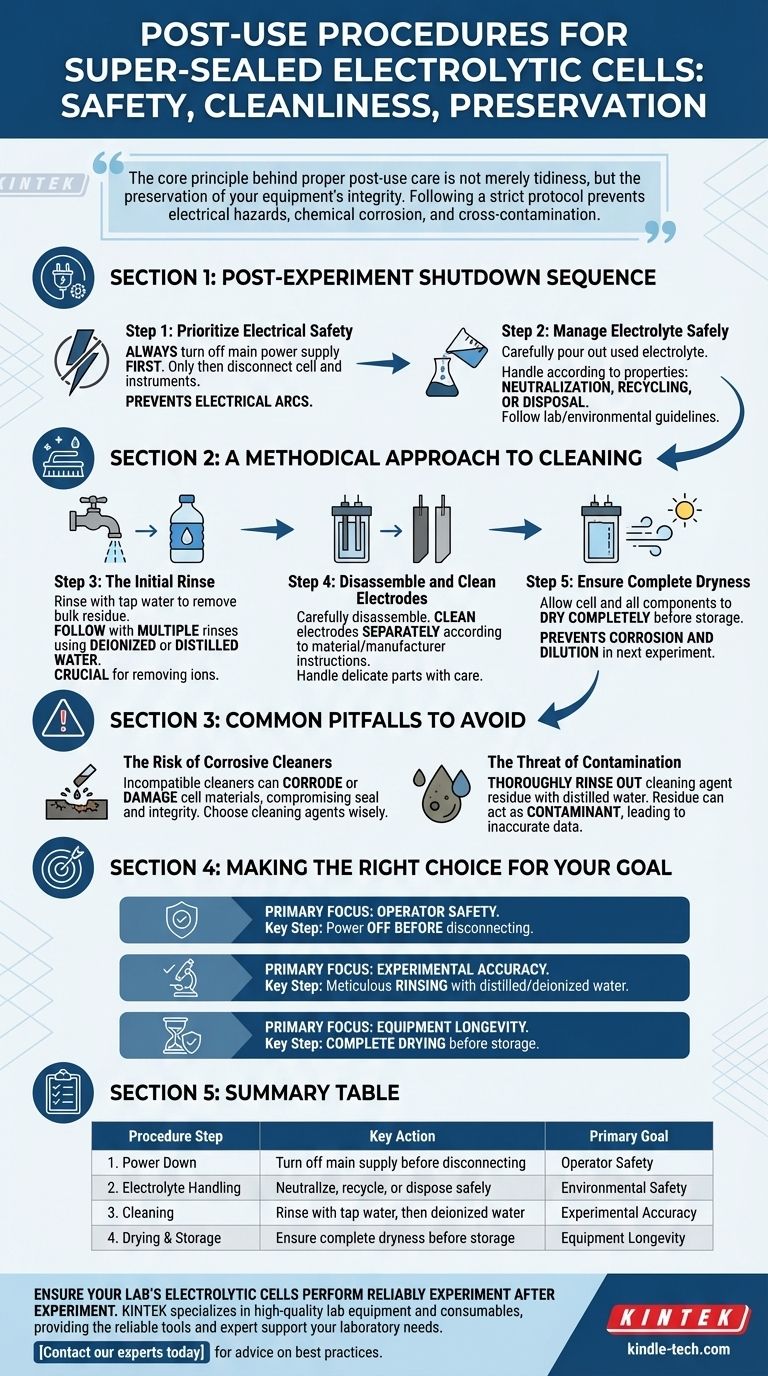

Proper post-use procedure for a super-sealed electrolytic cell is a systematic process focused on safety, cleanliness, and preservation. The correct sequence is to first power down all equipment, then safely handle the electrolyte, followed by a thorough, multi-stage cleaning of the cell and electrodes, and finally, proper storage in a clean, dry environment.

The core principle behind proper post-use care is not merely tidiness, but the preservation of your equipment's integrity. Following a strict protocol prevents electrical hazards, chemical corrosion, and cross-contamination that could compromise future experimental results.

The Post-Experiment Shutdown Sequence

The first steps after your experiment concludes are centered on ensuring safety and properly managing the chemical components.

Step 1: Prioritize Electrical Safety

Always turn off the main power supply first.

Only after the power is off should you disconnect the cell from the circuitry and other instruments. This sequence is critical for preventing electrical arcs and other potential safety incidents.

Step 2: Manage the Electrolyte Safely

Carefully pour out the used electrolyte from the cell.

Handle the substance according to its specific chemical properties. This may involve neutralization, recycling, or disposal following established lab safety and environmental guidelines.

A Methodical Approach to Cleaning

Thorough cleaning is essential for preventing corrosion, blockages, and contamination that can affect the accuracy of subsequent experiments.

Step 3: The Initial Rinse

Begin by rinsing the electrolytic cell and its components with tap water to remove the bulk of the residual electrolyte.

Follow this with multiple rinses using deionized or distilled water. This step is crucial for removing any remaining ions and ensuring the cell is completely clean.

Step 4: Disassemble and Clean Electrodes

Carefully disassemble the electrodes from the cell assembly.

Clean the electrodes separately according to their material and the manufacturer's instructions. They are often delicate and require specific care.

Step 5: Ensure Complete Dryness

Allow the electrolytic cell and all its components to dry completely before storage. Residual moisture can lead to corrosion or dilute the electrolyte in your next experiment.

Common Pitfalls to Avoid

The most common mistakes occur during the cleaning phase, particularly when dealing with stubborn residues.

The Risk of Corrosive Cleaners

If distilled water is insufficient, you may need to soak the cell in a suitable solvent or a dilute acid or alkali solution.

The choice of cleaning agent is critical. A chemically incompatible cleaner can corrode or permanently damage the cell materials, compromising its seal and structural integrity.

The Threat of Contamination

Always ensure the cleaning agent is thoroughly rinsed out with distilled water after use. Any residue from the cleaner itself can act as a contaminant in your next experiment, leading to inaccurate data.

Making the Right Choice for Your Goal

Your specific priorities will determine which steps of the post-use procedure demand the most attention.

- If your primary focus is operator safety: The most critical step is to always turn off the power supply before disconnecting any cables to prevent electrical arcing.

- If your primary focus is experimental accuracy: Meticulous rinsing with distilled or deionized water to remove all residues is non-negotiable.

- If your primary focus is equipment longevity: Ensuring the cell and electrodes are completely dry before storage is the key to preventing long-term corrosion.

By treating post-use procedures with the same precision as the experiment itself, you protect your investment and ensure the continued reliability of your results.

Summary Table:

| Procedure Step | Key Action | Primary Goal |

|---|---|---|

| 1. Power Down | Turn off main supply before disconnecting | Operator Safety |

| 2. Electrolyte Handling | Neutralize, recycle, or dispose safely | Environmental Safety |

| 3. Cleaning | Rinse with tap water, then deionized water | Experimental Accuracy |

| 4. Drying & Storage | Ensure complete dryness before storage | Equipment Longevity |

Ensure your lab's electrolytic cells perform reliably experiment after experiment.

Proper maintenance is key to safety and accurate results. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable tools and expert support your laboratory needs.

Contact our experts today to find the right equipment and get advice on best practices for your specific applications.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell for Coating Evaluation

- H Type Electrolytic Cell Triple Electrochemical Cell

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

People Also Ask

- What materials are used for the caps of the sealed and non-sealed electrolysis cells? PTFE vs. POM Explained

- Why is a dual-chamber secondary container required in water electrolysis? Ensure Clean Gas & Protect Equipment

- What are the guidelines for high-temperature sterilization of the multifunctional electrolytic cell? Avoid Permanent Damage to Your PTFE Lid

- What is the function of a single-compartment flow electrochemical reactor? Optimize Your Chlorate Synthesis Today

- What is the role of a standard three-electrode electrochemical reactor? Evaluate Corrosion Resistance with Precision

- What is the specific process function of the electrolysis system in seawater hydrogen production? Unlocking Fuel Growth

- Why must a PEO reaction cell have cooling and stirring? Control Heat & Uniformity for Superior Plasma Electrolytic Oxidation

- What are the key precautions to take when cleaning the electrolysis cell? Ensure Lab Safety and Accurate Results