The properties of a sintered material are not fixed, but are intentionally engineered during its creation. Unlike materials that are cast or forged, a sintered part's final characteristics—such as its density, mechanical strength, and hardness—are a direct result of precisely controlling the manufacturing process. The defining feature is a microstructure composed of fused particles, which can be tailored for a specific application.

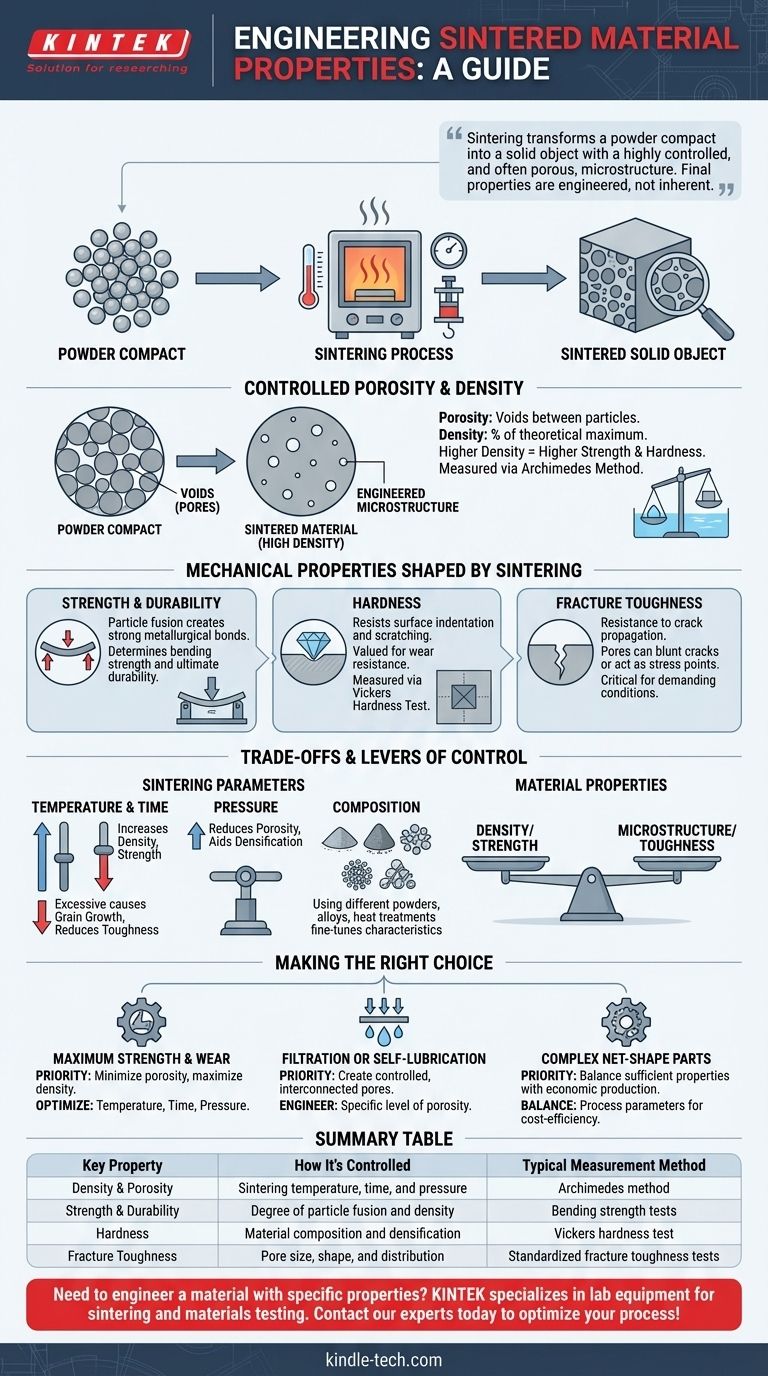

The core principle to understand is that sintering transforms a powder compact into a solid object with a highly controlled, and often porous, microstructure. The final properties are not inherent to the base material alone but are a direct function of this engineered microstructure, which is dictated by the sintering parameters.

The Defining Characteristic: Controlled Porosity and Density

The most fundamental property that separates sintered materials from their fully dense counterparts is the intentional control over porosity. This is the foundation from which other properties are derived.

From Powder to Solid

Sintering is a thermal process that fuses particles together at a temperature below the material's melting point. Because the material doesn't melt and flow, microscopic voids remain between the original powder particles.

These voids form a network of pores, and the volume of these pores defines the material's porosity and its overall density.

The Role of Density

The density of a sintered part is typically expressed as a percentage of the theoretical maximum density of the base material. A part with 95% density has 5% of its volume composed of pores.

This level of density is directly linked to most mechanical properties. Generally, higher density leads to higher strength and hardness.

Measuring Density

The volume density of a sintered component is a critical quality control metric. It is commonly measured using the Archimedes method, a straightforward technique involving weighing the part in air and then in a liquid of known density.

How Sintering Shapes Mechanical Properties

The unique microstructure created by sintering directly influences the material's performance under stress. This allows for a wide range of mechanical behaviors to be achieved.

Strength and Durability

The fusion of particles creates strong metallurgical bonds at the grain boundaries. This network determines the material's ultimate strength and durability.

Properties like bending strength are measured to quantify how much stress the material can withstand before it deforms or fractures, making it a critical parameter for structural components.

Hardness

Sintered materials are often valued for their hardness and wear resistance. Hardness reflects the material's ability to resist localized surface indentation or scratching.

This property is typically quantified using a standard test, such as the Vickers hardness test, which presses a diamond indenter into the material's surface.

Fracture Toughness

Fracture toughness measures a material's resistance to the propagation of cracks. The pores within a sintered material can sometimes act to blunt or arrest a crack, but they can also act as stress concentration points.

Controlling the size, shape, and distribution of these pores is therefore critical for creating components that can withstand demanding service conditions without catastrophic failure.

Understanding the Trade-offs and Levers of Control

You cannot change one property without affecting others. The key to successful sintering is understanding how to manipulate the process parameters to achieve the optimal balance for your specific goal.

The Impact of Temperature and Time

Higher sintering temperatures and longer holding times promote greater particle fusion, which increases density and strength.

However, excessive heat or time can also lead to unwanted grain growth. Larger grains can, in some cases, reduce the material's strength and toughness, presenting a critical process trade-off.

The Role of Pressure

Applying external pressure during the sintering process physically forces the particles closer together, significantly aiding densification.

This is a powerful lever for reducing porosity and achieving near-fully dense components with superior mechanical properties.

The Influence of Composition

The final properties are not solely dependent on the process. Using different starting powders, creating alloys, or applying subsequent heat treatments provides an additional layer of control to fine-tune material characteristics.

Making the Right Choice for Your Goal

Sintering allows you to engineer a material for a specific outcome. By adjusting the process parameters, you can prioritize the properties that matter most for your application.

- If your primary focus is maximum strength and wear resistance: Your goal is to minimize porosity and achieve the highest possible density by optimizing temperature, time, and pressure.

- If your primary focus is filtration or self-lubrication: Your goal is to create a controlled, interconnected network of pores, intentionally engineering a specific level of porosity rather than eliminating it.

- If your primary focus is producing a complex, net-shape part economically: Your goal is to balance the process parameters to achieve sufficient mechanical properties without the cost of more aggressive or time-consuming cycles.

Ultimately, sintering offers a powerful method for creating materials with precise, application-specific properties that are defined by their microstructure.

Summary Table:

| Key Property | How It's Controlled | Typical Measurement Method |

|---|---|---|

| Density & Porosity | Sintering temperature, time, and pressure | Archimedes method |

| Strength & Durability | Degree of particle fusion and density | Bending strength tests |

| Hardness | Material composition and densification | Vickers hardness test |

| Fracture Toughness | Pore size, shape, and distribution | Standardized fracture toughness tests |

Need to engineer a material with specific properties? KINTEK specializes in lab equipment and consumables for sintering and materials testing. Our expertise helps you achieve the precise density, strength, and microstructure your application demands. Contact our experts today to optimize your sintering process and create superior materials!

Visual Guide

Related Products

- Mesh belt controlled atmosphere furnace

- Spark Plasma Sintering Furnace SPS Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How does an atmosphere furnace ensure quality in BN nanotube synthesis? Precision Control for Cup-Stacked Structures

- Why is a high-precision atmosphere furnace essential for high-nickel cathode sintering? Unlock Battery Performance

- Why Use Ultra-High Vacuum Furnaces for LLZO? Ensure Chemical Stability & Interface Integrity in Solid Electrolytes

- What is the core function of a high-temperature atmosphere sintering furnace in the fabrication of Ni-Al2O3-TiO2 composites?

- Why is precise temperature control in a sintering furnace critical for NASICON electrolytes? Ensure Material Purity