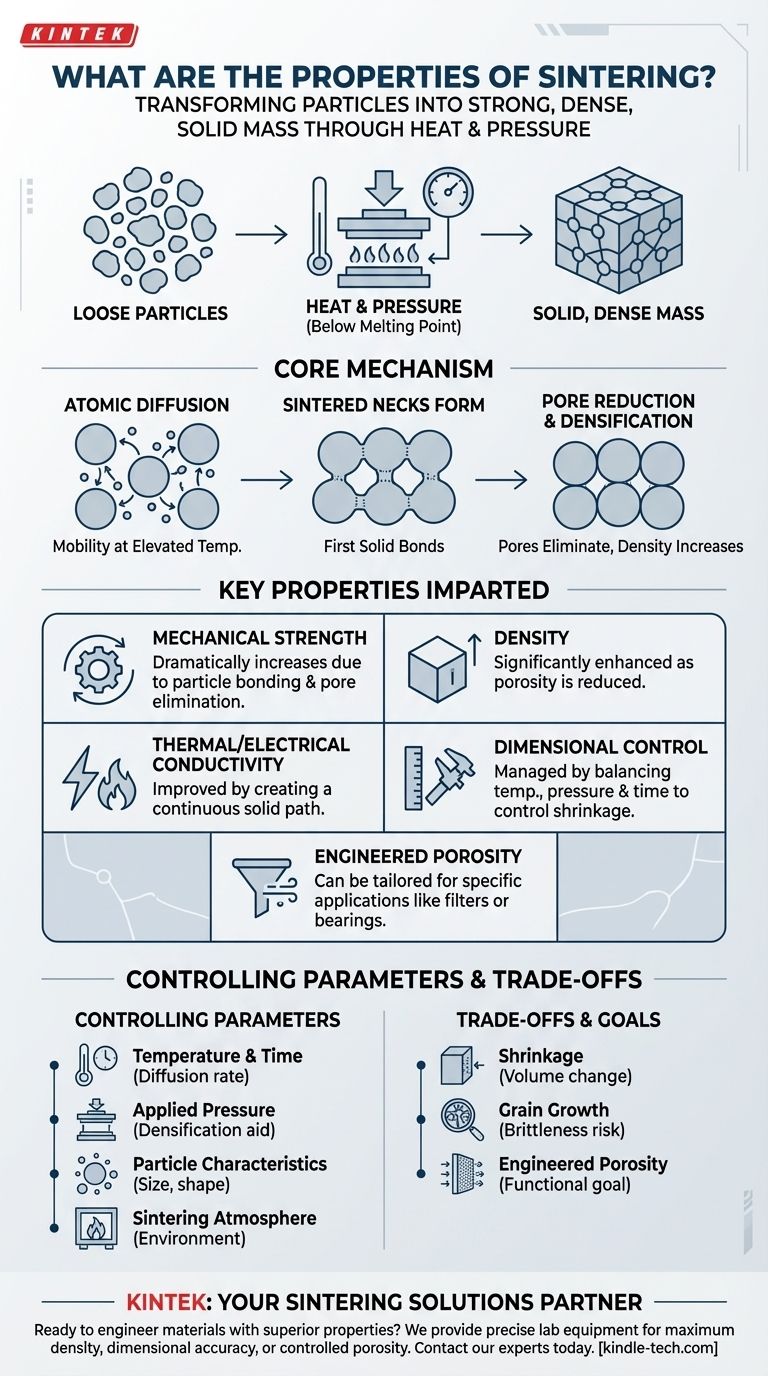

The fundamental property of sintering is its ability to transform a loose collection of particles into a strong, dense, solid mass using heat and pressure. This process works below the material's melting point, relying on atomic diffusion to create powerful bonds between particles. The primary results are significantly increased material strength, density, and durability, along with reduced porosity and enhanced thermal and electrical conductivity.

Sintering is not a single outcome but a highly controllable transformation of a material's microstructure. By precisely manipulating heat, pressure, and time, you can engineer a final component with specific performance characteristics, from maximum density to calculated, functional porosity.

How Sintering Fundamentally Alters Material Structure

Sintering creates its desirable properties by reorganizing the material at a microscopic level. The process is driven by the reduction of surface energy as individual particles fuse into a larger, more stable mass.

The Core Mechanism: Atomic Diffusion

At elevated temperatures, the atoms within the material become more mobile. They migrate across the surfaces of adjacent particles, effectively building bridges between them without the material ever becoming liquid.

Formation of "Sintered Necks"

The initial stage of this process is the formation of "necks" at the points where particles touch. These necks are the first solid bonds, and their growth marks the beginning of the transformation from a powder compact to a solid object.

Pore Reduction and Densification

As these necks grow and particles pull closer together, the empty spaces (pores) between them shrink and are eventually eliminated. This reduction in porosity is what leads to a highly densified, less permeable final product.

Key Properties Imparted by Sintering

The microstructural changes that occur during sintering directly translate into enhanced macroscopic properties that are critical for engineering applications.

Mechanical Strength and Hardness

By fusing individual particles into a continuous solid, sintering creates a structure that can effectively distribute and resist mechanical stress. This results in a dramatic increase in hardness, toughness, and overall strength compared to the un-sintered powder.

Enhanced Density

The direct consequence of eliminating porosity is an increase in density. In many applications, particularly in metallurgy and advanced ceramics, achieving near-total density is the primary objective of the sintering process.

Improved Thermal and Electrical Conductivity

Pores are filled with air, which is an excellent insulator. By eliminating these insulating gaps, sintering creates a continuous path through the material, allowing heat and electricity to flow much more efficiently.

Modified Optical Properties

In certain ceramic materials, the pores are the primary cause of light scattering, making the material opaque. By eliminating these pores, sintering can produce a highly dense microstructure that is translucent or even fully transparent.

Understanding the Controlling Parameters

The final properties of a sintered part are not accidental; they are the direct result of carefully controlled process variables. Understanding these levers is key to achieving the desired outcome.

Temperature and Time

Higher sintering temperatures and longer holding times accelerate atomic diffusion. This generally leads to greater densification and strength, but must be carefully managed to avoid negative effects.

Applied Pressure

Applying external pressure during the process forces particles into closer contact. This significantly aids densification and allows the process to occur at lower temperatures or in shorter times.

Particle and Material Characteristics

The initial particle size, shape, and the material's inherent conductivity all influence how it will behave during sintering. Finer powders, for instance, often sinter more readily due to their higher surface area.

Sintering Atmosphere

The chemical environment inside the furnace is critical. A controlled atmosphere can be used to prevent oxidation, remove contaminants from the powder surface, or even facilitate the diffusion of alloying elements like nickel or copper into the main material.

The Trade-off: Density vs. Dimensional Control

While sintering is an incredibly powerful process, it is governed by a fundamental set of trade-offs that every engineer must consider.

The Challenge of Shrinkage

As pores are eliminated and the part becomes denser, it will inevitably shrink. This change in volume can be significant and must be precisely calculated and accounted for in the initial design to achieve the correct final dimensions.

The Risk of Grain Growth

If the temperature is too high or the time too long, the grains within the material can grow excessively large. While the part may be dense, oversized grains can often make a material more brittle, reducing its overall performance.

Engineered Porosity: A Deliberate Choice

Full density is not always the goal. For applications like filters, catalysts, or self-lubricating bearings, the objective is to create just enough bonding to ensure strength while deliberately leaving a network of interconnected pores. This is a perfect example of using sintering to engineer a specific material function.

Matching the Process to Your Goal

The right approach to sintering depends entirely on the intended application of the final component.

- If your primary focus is maximum strength and density: You must optimize for higher temperatures and pressures, while carefully managing component shrinkage and preventing excessive grain growth.

- If your primary focus is dimensional accuracy for complex shapes: Consider specialized methods like reaction sintering, which can achieve high densification with minimal part shrinkage.

- If your primary focus is creating a functional porous material: The goal is to encourage particle bonding for structural integrity while using lower temperatures or shorter times to prevent the complete elimination of pores.

Ultimately, understanding these properties allows you to treat sintering not just as a fabrication step, but as a powerful tool for advanced material design.

Summary Table:

| Property | Description |

|---|---|

| Mechanical Strength | Dramatically increases due to particle bonding and pore elimination. |

| Density | Significantly enhanced as porosity is reduced. |

| Thermal/Electrical Conductivity | Improved by creating a continuous solid path. |

| Dimensional Control | Managed by balancing temperature, pressure, and time to control shrinkage. |

| Engineered Porosity | Can be tailored for specific applications like filters or bearings. |

Ready to engineer materials with superior properties?

KINTEK specializes in providing the precise lab equipment and consumables needed to master the sintering process. Whether your goal is maximum density, dimensional accuracy, or controlled porosity, our solutions help you achieve the exact material performance you require.

Contact our experts today to discuss how we can support your laboratory's sintering and material design challenges.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is sintering with an example? A Guide to Fusing Powders into Solid Parts

- How well does graphite transfer heat? Unlock Superior Thermal Management for Your Electronics

- What is the purpose of sputter coating? Achieve Atomic-Scale Precision and Uniformity

- What are the advantages of a batch furnace? Achieve Unmatched Flexibility and Control

- Is there a way to laminate without a laminator? Yes, with these simple DIY methods.

- Does pyrolysis emit CO2? Unpacking the Carbon Footprint of Waste-to-Energy

- Are wood pellets biomass? Understanding the Renewable Fuel Powering Modern Heating

- What is a furnace used in the lab? Your Guide to High-Temperature Precision