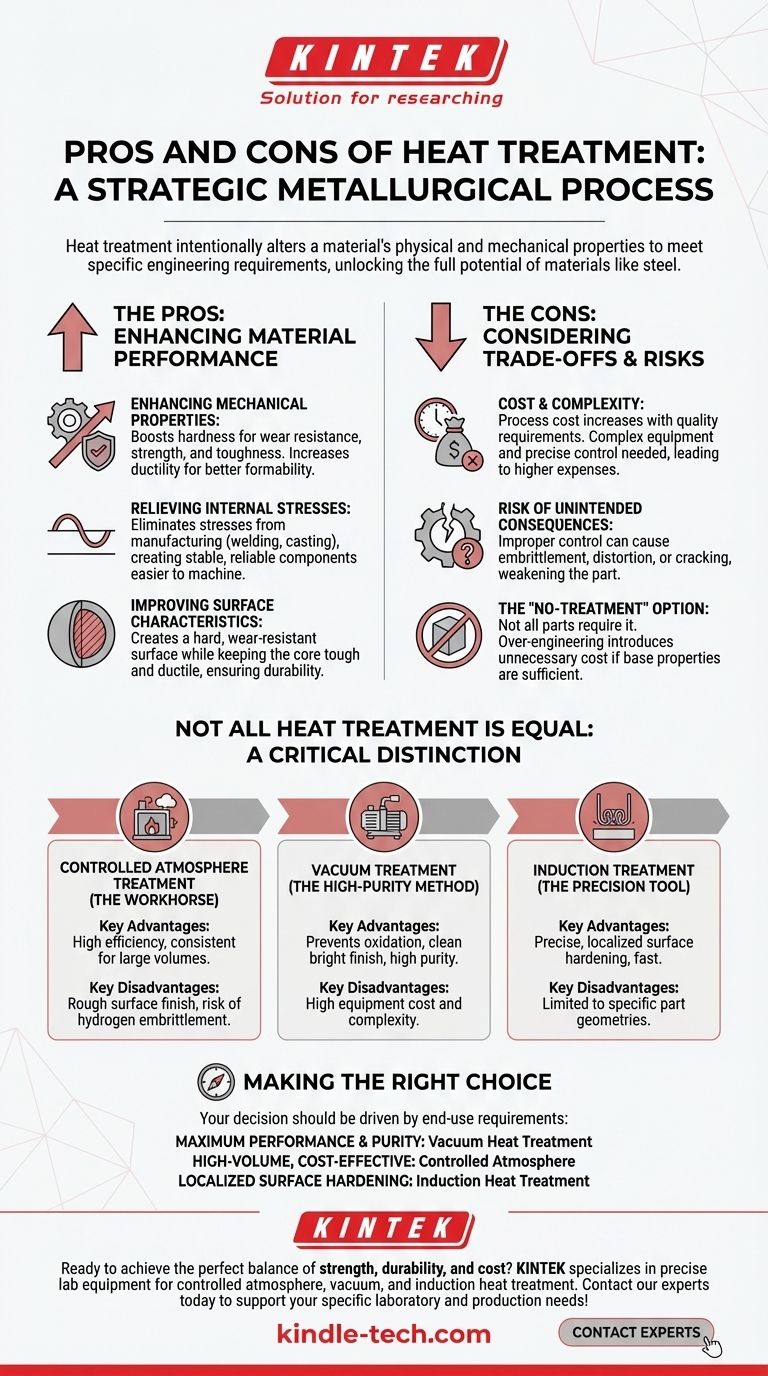

At its core, heat treatment is a powerful metallurgical process used to intentionally alter a material's physical and mechanical properties to meet specific engineering requirements. The primary advantage is the ability to significantly enhance characteristics like strength, hardness, and wear resistance, while the main disadvantages involve process complexity, cost, and the risk of introducing new material defects if not controlled precisely.

The decision to use heat treatment is not a simple "yes or no." It's a strategic choice about which specific method offers the right balance of performance enhancement, surface finish, and cost for your component's intended function.

The Fundamental Purpose: Why Heat Treat at All?

Heat treatment is a foundational manufacturing step that unlocks the full potential of a material, most notably steel. By controlling cycles of heating and cooling, you can manipulate the material's internal microstructure.

Enhancing Mechanical Properties

The most common reason for heat treatment is to improve a material's mechanical behavior. This can mean increasing its hardness for better wear resistance or boosting its strength and toughness to handle higher loads.

Conversely, processes like annealing can increase ductility and reduce brittleness, making a material easier to form or shape without fracturing.

Relieving Internal Stresses

Manufacturing processes like welding, casting, or heavy machining introduce internal stresses into a part. These stresses can lead to warping or cracking over time.

Heat treatment can effectively relieve these stresses, creating a more stable and reliable component that is easier to machine accurately in subsequent steps.

Improving Surface Characteristics

For parts that experience friction or abrasion, heat treatment can create a very hard, wear-resistant surface layer while keeping the core of the material tough and ductile. This creates a component that is durable without being entirely brittle.

The Critical Distinction: Not All Heat Treatment is Equal

The terms "pros and cons" are highly dependent on the specific type of heat treatment being used. The three common methods below illustrate different sets of trade-offs.

Controlled Atmosphere Treatment (The Workhorse)

This method involves heating parts in a furnace with a specific, controlled gas mixture to prevent unwanted chemical reactions.

Its main advantages are high efficiency, suitability for large volumes, and consistent quality, which can reduce labor and overall processing steps.

However, it requires complex equipment and can result in a rough, non-bright surface. It also carries the risk of hydrogen embrittlement in certain steels if the atmosphere isn't perfectly managed.

Vacuum Treatment (The High-Purity Method)

In this process, parts are heated in a vacuum, eliminating almost all atmospheric gases.

This is its key advantage: it completely prevents oxidation and decarburization, resulting in a clean, bright part with no need for post-process cleaning. It also removes trapped gases like hydrogen, significantly improving toughness and fatigue life.

The primary disadvantage is the high cost and complexity of vacuum furnace equipment, making it best suited for high-performance, high-value components.

Induction Treatment (The Precision Tool)

Induction heating uses an electromagnetic coil to generate heat directly within a targeted area of the part.

Its unique benefit is precision. By adjusting the frequency of the electric current, you can control the exact depth of heating. This is ideal for hardening only a specific surface, like the teeth on a gear, while leaving the core unaffected.

Understanding the Trade-offs and Risks

Choosing a heat treatment process is an exercise in balancing engineering goals with practical constraints.

Cost vs. Performance

There is a direct relationship between the cost of the process and the quality of the result. A simple stress relief cycle is inexpensive, while a high-purity vacuum treatment for a critical aerospace part is a significant investment.

The Risk of Unintended Consequences

An improperly controlled process can do more harm than good. Using the wrong atmosphere can erode surface elements or cause embrittlement, fundamentally weakening the part. Overheating or cooling too quickly can cause distortion or cracking.

The "No-Treatment" Option

It is critical to remember that not every part requires heat treatment. If the material's base properties are sufficient for the application, adding a heat treatment step only introduces unnecessary cost and complexity. Over-engineering is a common and costly pitfall.

Making the Right Choice for Your Goal

Your decision should be driven by the end-use requirements of the component.

- If your primary focus is maximum performance, purity, and a clean finish: Vacuum heat treatment is the superior choice for preventing oxidation and improving material integrity.

- If your primary focus is high-volume, cost-effective production for general-purpose parts: Controlled atmosphere treatment offers an excellent balance of efficiency and property enhancement, provided you can accept the surface finish trade-offs.

- If your primary focus is localized surface hardening with a tough core: Induction heat treatment provides unparalleled precision and speed for specific geometric features.

Ultimately, selecting the right thermal process is a crucial engineering decision that directly impacts the final performance and reliability of your product.

Summary Table:

| Method | Key Advantages | Key Disadvantages |

|---|---|---|

| Controlled Atmosphere | High efficiency, consistent for large volumes | Rough surface finish, risk of hydrogen embrittlement |

| Vacuum Treatment | Prevents oxidation, clean bright finish, high purity | High equipment cost and complexity |

| Induction Treatment | Precise, localized surface hardening, fast | Limited to specific part geometries |

Ready to achieve the perfect balance of strength, durability, and cost for your components?

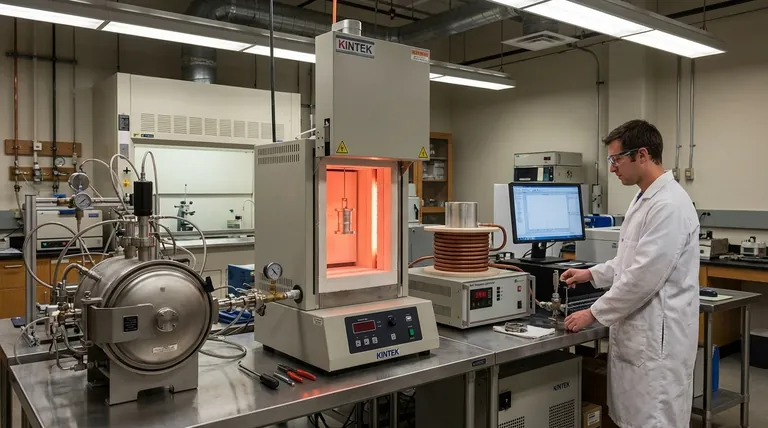

At KINTEK, we specialize in providing the precise lab equipment and consumables needed for controlled atmosphere, vacuum, and induction heat treatment processes. Whether you're in aerospace, automotive, or general manufacturing, our solutions help you enhance material performance, reduce defects, and improve product reliability.

Contact our experts today to discuss how we can support your specific laboratory and production needs!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost