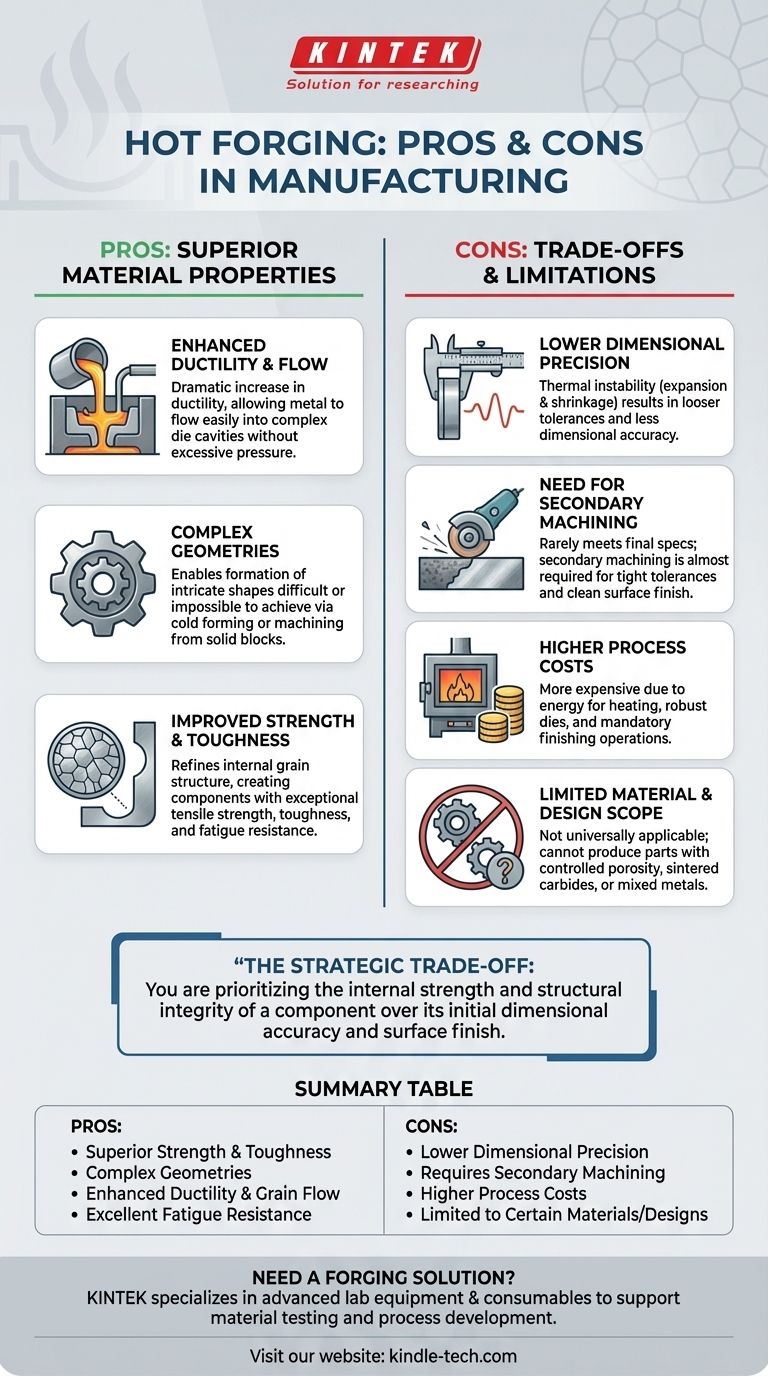

In manufacturing, hot forging is a process defined by its use of extreme heat to shape metal, making it exceptionally malleable. Its primary advantage is the ability to produce parts with superior strength and form complex geometries, but this comes at the cost of lower dimensional precision and the frequent need for secondary machining.

The choice to use hot forging is a strategic trade-off. You are prioritizing the internal strength and structural integrity of a component over its initial dimensional accuracy and surface finish.

The Primary Advantage: Superior Material Properties

Hot forging involves heating metal above its recrystallization temperature, which fundamentally changes its behavior during forming. This unlocks several key performance benefits.

Enhanced Ductility and Flow

By heating the material, its ductility is dramatically increased. This allows the metal to flow more easily and fill complex die cavities without excessive pressure or the risk of work hardening during the process.

Creation of Complex Geometries

The high malleability of the heated metal enables the formation of intricate shapes that would be difficult or impossible to achieve through cold forming or machining from a solid block. This is a significant advantage for complex structural parts.

Improved Strength and Toughness

The forging process refines the metal's internal grain structure, forcing the grains to align with the shape of the part. This directional grain flow creates components with exceptional tensile strength, toughness, and fatigue resistance.

Understanding the Trade-offs and Limitations

The same heat that provides hot forging's benefits also introduces its most significant drawbacks. Understanding these is critical for making an informed decision.

Lower Dimensional Precision

High temperatures cause the metal workpiece to expand. As it cools, it shrinks in a less predictable manner than in a cold process. This thermal instability results in looser tolerances and less dimensional accuracy in the final part.

The Need for Secondary Machining

Due to the lower precision and the formation of a rough, oxidized surface layer (scale) at high temperatures, hot-forged parts rarely meet final specifications directly from the die. Secondary machining is almost always required to achieve tight tolerances and a clean surface finish, which adds to both project cost and lead time.

Higher Process Costs

Hot forging is often more expensive than other methods. Costs are driven by the energy required for heating furnaces, the more robust and expensive dies needed to withstand thermal cycling, and the mandatory secondary finishing operations.

Limited Material and Design Scope

The process is not universally applicable. Hot forging cannot be used to create parts with controlled porosity (like porous bearings), produce sintered carbides, or mix multiple metals. Furthermore, producing very small, finely detailed parts is impractical without extensive machining.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process requires aligning its capabilities with your project's most critical requirements.

- If your primary focus is maximum strength and fatigue resistance: Hot forging is the superior choice for critical components where material failure is not an option, such as in automotive or aerospace applications.

- If your primary focus is tight tolerances and a fine surface finish: You should plan for significant secondary machining or consider alternative processes like cold forging or direct CNC machining from the start.

- If your primary focus is cost-effectiveness on a short production run: The high cost of die production makes hot forging economically challenging for low-volume projects.

Ultimately, selecting hot forging is a deliberate engineering decision that prioritizes internal material strength over as-forged dimensional precision.

Summary Table:

| Pros of Hot Forging | Cons of Hot Forging |

|---|---|

| Superior strength & toughness | Lower dimensional precision |

| Complex geometries possible | Requires secondary machining |

| Enhanced ductility & grain flow | Higher process & energy costs |

| Excellent fatigue resistance | Limited to certain materials/designs |

Need a forging solution that balances strength, precision, and cost? KINTEK specializes in providing advanced lab equipment and consumables to support your material testing and process development. Whether you're researching metal properties or optimizing your forging parameters, our solutions help you make data-driven decisions. Contact our experts today to discuss how we can enhance your laboratory's capabilities and ensure your manufacturing success.

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- What are the advantages of using a hot press for Li7P2S8I0.5Cl0.5? Boost Conductivity with Precision Densification

- How does a laboratory hot press improve the microscopic structure of polymer-ceramic composite cathodes? | KINTEK

- What is a hydraulic floor press used for? A Versatile Tool for Industrial and Lab Applications

- Why is a laboratory hot press required for Oxygen Depolarized Cathodes? Ensure Precision Molding and Conductivity.