Proper maintenance of a glassy carbon sheet involves a multi-step process of mechanical polishing, chemical or electrochemical cleaning, and careful handling. The primary goal is to create and preserve a clean, smooth, and electrochemically active surface, which is critical for obtaining reproducible and accurate experimental results. This process must be performed before first use and repeated whenever performance degradation is observed.

The core principle of glassy carbon maintenance is not just cleaning, but a systematic restoration of the electrode surface. Effective maintenance is a cycle of polishing to restore physical smoothness, cleaning to remove chemical contaminants, and verifying performance to ensure the electrode is ready for precise measurement.

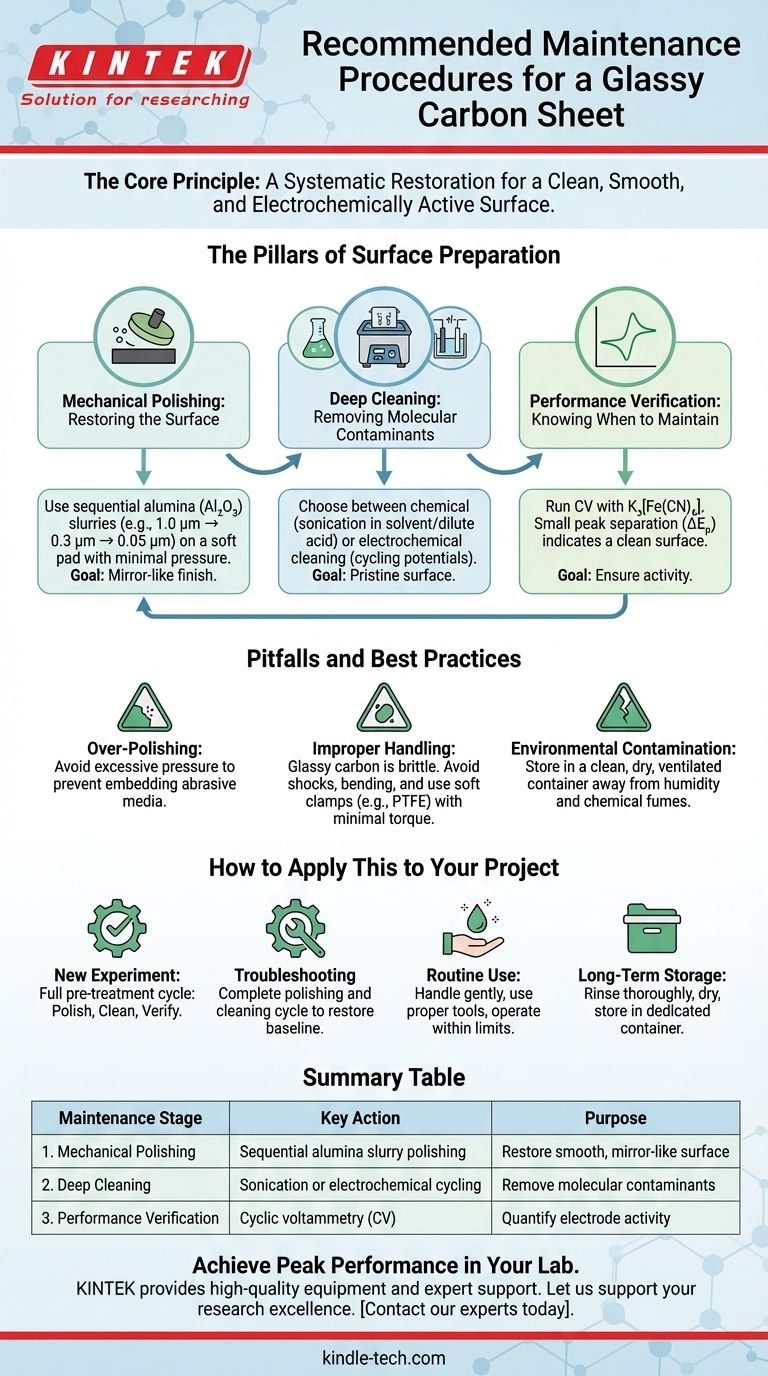

The Pillars of Surface Preparation

Effective maintenance can be broken down into three essential stages: mechanical polishing, deep cleaning, and performance verification. Each stage addresses a different type of surface degradation.

1. Mechanical Polishing: Restoring the Surface

The first step is always to restore the physical integrity of the surface. Polishing removes microscopic scratches, embedded impurities, and fouled layers that accumulate during use.

A standard polishing procedure involves using a sequence of decreasingly coarse polishing agents.

- Start with rough polishing (e.g., 1.0 µm alumina powder) only if the surface is severely scratched or contaminated.

- Proceed with fine polishing using alumina (Al₂O₃) slurries in sequence, such as 0.3 µm followed by a final polish with 0.05 µm.

- Apply the slurry onto a soft, clean polishing pad or chamois cloth. Polish the sheet in a figure-eight motion to ensure even treatment.

After polishing, the sheet must be thoroughly rinsed with ultra-pure water to remove all abrasive particles. The goal is a perfectly smooth, mirror-like finish with no visible scratches.

2. Deep Cleaning: Removing Molecular Contaminants

Polishing creates a smooth surface, but it doesn't always remove adsorbed organic or inorganic molecules. A deep cleaning step is required to achieve a truly pristine surface.

You can choose between two methods:

- Chemical Cleaning: This involves sonicating the polished sheet in a solvent like ethanol or high-purity water. For more stubborn contamination, brief immersion in dilute nitric acid can be effective, but avoid prolonged contact with strong acids or bases.

- Electrochemical Cleaning: This is an active method where the electrode is repeatedly cycled between positive and negative potentials (e.g., +0.8V to -1.8V) in a clean electrolyte. This process effectively strips adsorbed species from the surface.

After any cleaning method, a final, exhaustive rinse with ultra-pure water is mandatory.

3. Performance Verification: Knowing When to Maintain

You should not rely on visual inspection alone. The most reliable way to assess the electrode's condition is to test its electrochemical performance.

Use a standard, well-behaved redox couple like potassium ferricyanide (K₃[Fe(CN)₆]) in a solution of potassium chloride (KCl). Run a cyclic voltammogram (CV).

A clean, active glassy carbon surface will produce sharp, well-defined oxidation and reduction peaks. A key diagnostic is the peak-to-peak separation (ΔEp). A small ΔEp indicates fast electron transfer, while a large or increasing ΔEp signifies a sluggish, fouled surface that requires maintenance.

Understanding the Pitfalls and Best Practices

While the procedures are straightforward, improper technique can cause more harm than good. Awareness of common pitfalls is crucial for extending the life of your electrode.

The Risk of Over-Polishing

Aggressive or overly frequent polishing can slowly wear away the material. More importantly, it can embed the polishing media (alumina particles) into the carbon surface, which can interfere with your measurements. Always use minimal pressure and let the abrasive do the work.

The Dangers of Improper Handling

Glassy carbon is hard but extremely brittle. It can easily fracture from mechanical shock or stress.

- Avoid collisions with hard or sharp objects.

- Do not bend or apply excessive pressure to the sheet.

- Use appropriate clamps, preferably made of a soft material like PTFE, and apply minimal torque (e.g., no more than 0.5 N·m) during installation.

Preventing Environmental Contamination

The environment itself can be a source of contamination.

- Operate in a clean, dry, and non-corrosive atmosphere.

- Avoid use in high humidity or near strong magnetic fields.

- Store the electrode in a dry, ventilated container away from moisture and chemical fumes.

How to Apply This to Your Project

Your maintenance strategy should adapt to your immediate needs and observations.

- If your primary focus is preparing for a new, sensitive experiment: Perform the full pre-treatment protocol: polish sequentially, sonicate to clean, and verify performance with a standard redox couple before use.

- If your primary focus is troubleshooting poor results (e.g., broad or shifting CV peaks): Your surface is the most likely culprit. Perform a complete polishing and cleaning cycle to restore the electrode to a baseline state.

- If your primary focus is routine use and handling: Prioritize preventative care. Handle the sheet gently, use proper mounting tools, and always operate within its specified temperature and voltage limits.

- If your primary focus is long-term storage between projects: Rinse the electrode thoroughly with pure solvent, allow it to dry, and place it in a dedicated, clean container to prevent contamination.

Consistent and methodical maintenance is the foundation of reliable and reproducible electrochemical research.

Summary Table:

| Maintenance Stage | Key Action | Purpose |

|---|---|---|

| 1. Mechanical Polishing | Sequential polishing with alumina slurry (e.g., 1.0µm to 0.05µm) | Restore a smooth, mirror-like surface free of scratches and impurities. |

| 2. Deep Cleaning | Sonication in solvent or electrochemical cycling in clean electrolyte | Remove molecular contaminants (organic/inorganic) for a pristine surface. |

| 3. Performance Verification | Cyclic voltammetry with a standard redox couple (e.g., K₃[Fe(CN)₆]) | Quantify electrode activity; a small peak separation (ΔEp) indicates a clean surface. |

Achieve Peak Performance in Your Lab

Proper maintenance is key to the longevity and accuracy of your glassy carbon electrodes and other sensitive lab equipment. At KINTEK, we specialize in providing high-quality laboratory equipment and consumables, backed by expert technical support.

Whether you are setting up a new electrochemical workflow, troubleshooting inconsistent results, or simply need reliable supplies for routine maintenance, we are here to help.

Let KINTEK support your research excellence. Contact our experts today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Electrode Polishing Material for Electrochemical Experiments

- Optical Window Glass Substrate Wafer Quartz Plate JGS1 JGS2 JGS3

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What are the fundamental characteristics of glassy carbon? Discover its Unique Synergy of Properties

- What is the applicable potential range for an RVC glassy carbon sheet? Master Your Electrochemical Analysis

- What is the proper procedure for cleaning a glassy carbon sheet after use? A Definitive Guide to Ensure Reliable Results

- What are the typical physical specifications for glassy carbon sheets? Unlock Superior Performance for Your Lab

- Why is a glassy carbon disc electrode an indispensable consumable? Ensure Reliable Catalyst Evaluation Today