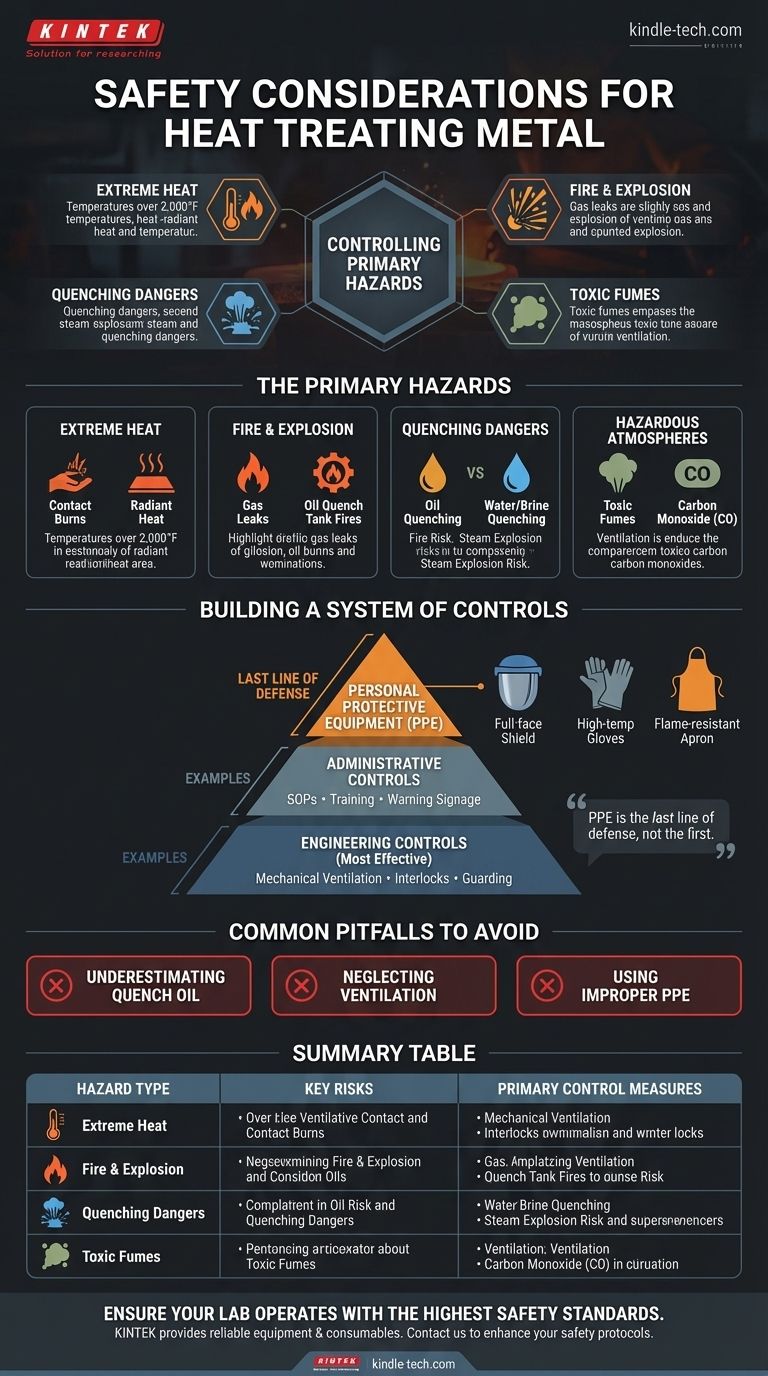

At its core, safety in metal heat treating revolves around controlling four primary hazards: the extreme heat of the furnace, the risk of fire or explosion from fuel sources and quench mediums, the potential for severe burns from hot materials and splashes, and the inhalation of hazardous fumes. A comprehensive safety plan must address each of these risks systematically.

The critical takeaway is that personal protective equipment (PPE) is the last line of defense, not the first. A truly safe operation is built upon a foundation of engineering controls like proper ventilation and equipment guards, reinforced by strict administrative procedures and rigorous training.

The Primary Hazards of Heat Treatment

Understanding the specific dangers is the first step toward mitigating them. Heat treatment introduces high-energy hazards into the workplace that demand respect and careful management.

Extreme Heat and Radiant Energy

The most obvious danger is the high temperature of the furnace, which can exceed 2,000°F (1,100°C). This presents two distinct burn risks.

First is contact burns from touching the furnace, tooling, or the workpiece itself. Second, and often underestimated, is radiant heat, which can cause serious burns and heat stress even from a distance.

Fire and Explosion Risks

Many heat-treating operations involve flammable materials. Gas-fired furnaces pose a risk of gas leaks and subsequent explosions if not properly maintained and ventilated.

The most common source of fire, however, is the oil quench tank. Plunging a red-hot part into oil can cause it to ignite if the oil's temperature is too high or if the part is not fully submerged correctly.

The Dangers of Quenching

The quenching process is often the most dynamic and hazardous phase. The choice of quenchant—oil, water, or brine—determines the specific risk.

Oil quenching carries a significant fire risk. A flare-up can quickly become an intense, difficult-to-control fire. Water and brine quenching avoid the fire hazard but introduce the risk of a steam explosion, where the water flashes violently into steam, splashing scalding water and potentially ejecting the workpiece.

Hazardous Atmospheres and Fumes

Heating metal, especially if it has coatings, rust, or residual cutting fluids, can release toxic fumes into the air. Furthermore, gas-fired furnaces can produce carbon monoxide (CO) if combustion is incomplete.

Without adequate ventilation, these gases can accumulate to dangerous levels, posing a serious respiratory hazard and, in the case of CO, a risk of asphyxiation.

Building a System of Controls

Safety is not a checklist; it's a system. A robust safety program prioritizes eliminating hazards at the source before relying on personal protective gear.

Engineering Controls: Your First Line of Defense

These are physical changes to the workspace that remove or reduce the hazard. They are the most effective form of protection.

Examples include mechanical ventilation systems (like fume hoods over quench tanks), furnace door interlocks that shut off power when opened, and physical guarding around hot zones and moving parts.

Administrative Controls: Safe Work Practices

These are the procedures and policies you follow to work safely. They require active participation from every operator.

Key practices include documented Standard Operating Procedures (SOPs), regular equipment inspection and maintenance schedules, clear warning signage, and thorough operator training.

Personal Protective Equipment (PPE): The Final Barrier

PPE is essential but should never be the only thing protecting you. It is designed to protect you if other controls fail.

Non-negotiable PPE for heat treating includes a full-face shield (not just safety glasses) to protect from splashes, high-temperature rated gloves (such as aluminized or aramid fiber gloves), and a flame-resistant apron or jacket. Proper leather footwear is also critical.

Common Pitfalls to Avoid

Complacency is the greatest threat in a familiar process. Many accidents occur when experienced operators take shortcuts or underestimate a known risk.

Underestimating Quench Oil

The danger of an oil quench fire cannot be overstated. Ensure your quench tank has a lid that can be used to smother a fire and that a Class B (flammable liquids) fire extinguisher is immediately accessible.

Neglecting Ventilation

Fume-related illness is an insidious hazard that builds up over time. Never perform heat treatment in a poorly ventilated space. Always verify that your exhaust systems are functioning before you begin work.

Using Improper PPE

Not all gloves are created equal. A standard leather work glove offers almost no protection from the temperatures involved. Using the wrong PPE provides a false sense of security and can lead to severe injury.

Making the Right Choice for Your Goal

Your safety protocol should scale with your operation, but the fundamental principles remain the same.

- If your primary focus is a small shop or hobbyist setup: Prioritize a dedicated, well-ventilated space, a proper quenching procedure, and investing in a full set of professional PPE from the start.

- If your primary focus is managing a professional facility: Implement robust engineering controls, maintain meticulous documentation of training and maintenance, and conduct regular safety audits to prevent procedural drift.

- If your primary focus is training new operators: Emphatically demonstrate the violent potential of quench fires and steam explosions to instill a deep and lasting respect for the process.

A systematic approach to safety is the foundation that enables consistent, high-quality, and repeatable results in your work.

Summary Table:

| Hazard Type | Key Risks | Primary Control Measures |

|---|---|---|

| Extreme Heat | Contact burns, radiant heat stress | Engineering controls (guards, interlocks), high-temperature PPE |

| Fire & Explosion | Gas leaks, oil quench tank fires | Ventilation, maintenance, Class B fire extinguishers, proper quenching SOPs |

| Quenching Dangers | Steam explosions (water/brine), oil flare-ups | Correct quenchant use, full submersion procedures, safety lids |

| Toxic Fumes | Carbon monoxide, metal coating fumes | Mechanical ventilation systems (fume hoods), air quality monitoring |

Ensure your lab operates with the highest safety standards. KINTEK specializes in providing reliable lab equipment and consumables for heat treatment processes, helping you protect your team and maintain a secure working environment. From furnaces to safety accessories, our solutions are designed to meet rigorous safety demands. Contact us today to discuss your laboratory's specific needs and enhance your safety protocols with KINTEK's trusted products.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- How does heat treatment process work? Tailor Material Properties for Your Application

- What are the three main heat treatments? Mastering Annealing, Hardening & Tempering

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing

- What is the difference between annealing hardening and tempering? Master Metal Properties for Your Lab