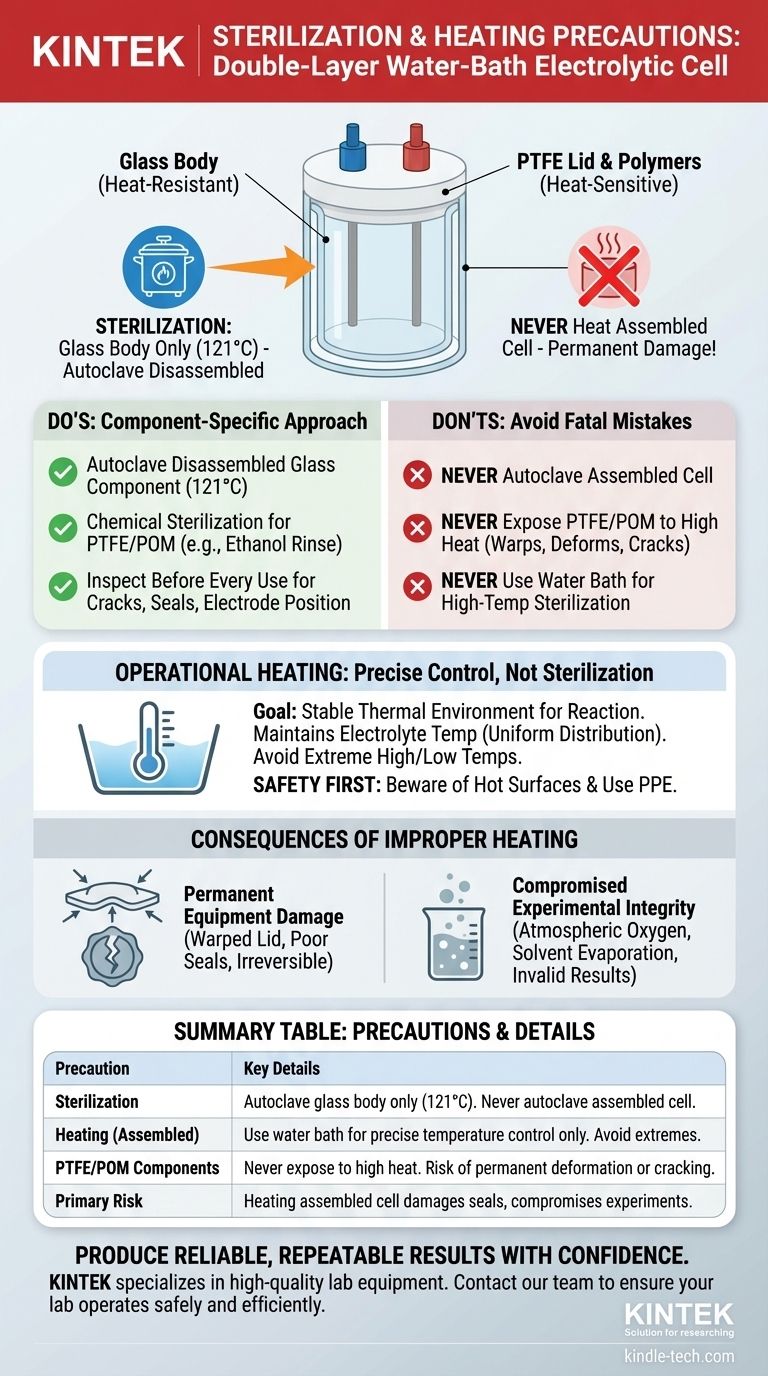

To ensure safety and experimental integrity, you must handle the sterilization and heating of a double-layer electrolytic cell by treating its components separately. The glass body can be safely sterilized via autoclaving at 121°C, but the complete, assembled cell must never be heated or autoclaved. The PTFE lid and other polymer components will permanently deform or crack under high heat, compromising the entire apparatus.

The core principle is that this cell is a multi-material system. Its operational success and longevity depend on respecting the distinct thermal limits of each material—the heat-resistant glass and the heat-sensitive PTFE polymer.

The Critical Distinction: Component vs. Assembly

The most common point of failure for this equipment stems from misunderstanding how different materials respond to heat. The cell's design requires a component-specific approach.

Sterilizing the Glass Body

The main body of the cell is made of glass, a material well-suited for high-temperature sterilization.

You can safely place the disassembled glass component in an autoclave at 121°C under high pressure to ensure sterility.

The Thermal Limits of PTFE and POM

The lid, inner core, and other fittings are often made from polymers like PTFE (Polytetrafluoroethylene) or POM (Polyoxymethylene).

These materials cannot withstand high temperatures. When heated, PTFE will expand and is unlikely to return to its original shape and size. This permanent deformation will prevent it from creating a proper seal. POM materials can simply crack.

The Cardinal Rule: Never Heat the Assembled Cell

Heating the fully assembled cell is the single most critical mistake to avoid.

Doing so will damage the PTFE and POM components, rendering the cell unusable. The differential expansion between hot glass and polymer parts can also create stress, leading to poor seals or even breakage.

Operational Heating: Managing the Water Bath

The double-layer design is for precise temperature control during an experiment, not for high-temperature sterilization. Its purpose is to create a stable thermal environment for your reaction.

The Goal of Precise Temperature Control

The external water bath allows you to maintain the electrolyte temperature within a very narrow range.

This mitigates heat generated during electrolysis and ensures uniform temperature distribution across the electrode surfaces, which is critical for consistent, repeatable results.

Avoiding Temperature Extremes

Strictly control the water bath temperature according to your experimental parameters.

Temperatures that are too high or too low can negatively affect reaction kinetics, product formation, and the overall accuracy of your results.

Personal Safety is Paramount

Always exercise caution when working with a heated water bath.

The apparatus and the electrolytic cell itself can become hot enough to cause burns. Avoid direct contact and use appropriate personal protective equipment.

Understanding the Trade-offs and Pitfalls

Improper heating has consequences beyond just the immediate damage. Understanding these risks is key to maintaining experimental integrity.

Risk of Permanent Equipment Damage

Heating the PTFE lid leads to warping. This is not a temporary issue; the lid will no longer fit or seal correctly.

This damage is irreversible and requires the replacement of the component.

Compromising Experimental Integrity

A deformed lid creates a poor seal. This can allow atmospheric oxygen to contaminate a deoxygenated solution or permit volatile solvents to evaporate.

Either of these outcomes can invalidate your electrochemical measurements and compromise the entire experiment.

Forgetting Routine Inspection

Before every use, especially after cleaning or sterilization, perform a thorough inspection.

Check the glass for micro-cracks, ensure seals are intact, and confirm the electrodes are correctly positioned. This simple habit prevents failed experiments and ensures safe operation.

Applying This to Your Work

Your approach should be dictated by your primary experimental goal and a respect for the equipment's material limitations.

- If your primary focus is sterility for bio-electrochemical studies: Autoclave the glass cell body separately and use a compatible chemical method, like an ethanol rinse, for the PTFE lid and other components.

- If your primary focus is precise temperature control for synthesis: Use the water bath strictly to maintain your target reaction temperature, ensuring it is stable and uniform.

- If your primary focus is equipment longevity and safety: Always disassemble the cell for cleaning, handle the glass components with care to prevent breakage, and never expose the polymer parts to high heat.

Understanding these material-specific precautions is the foundation for producing reliable, repeatable scientific results with this instrument.

Summary Table:

| Precautions | Key Details |

|---|---|

| Sterilization | Autoclave glass body only (121°C). Never autoclave assembled cell. |

| Heating (Assembled) | Use water bath for precise temperature control only. Avoid extremes. |

| PTFE/POM Components | Never expose to high heat. Risk of permanent deformation or cracking. |

| Primary Risk | Heating assembled cell damages seals, compromises experiments. |

Produce reliable, repeatable results with confidence. Proper handling of specialized lab equipment is fundamental to your research success. KINTEK specializes in high-quality lab equipment and consumables, including electrolytic cells, designed for durability and precision. Our experts can help you select the right equipment and provide guidance on best practices for your specific application. Contact our team today to ensure your lab operates safely and efficiently.

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell with Five-Port

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Electrolytic Electrochemical Cell for Coating Evaluation

People Also Ask

- What are the key features of the five-port water bath electrolytic cell? Precision Control for Electrochemical Experiments

- What are the key features of a double-layer water-bath electrolytic cell? Achieve Precise Temperature Control for Your Experiments

- How can the electrochemical reaction be controlled when using this electrolytic cell? Master Voltage, Current & Electrolyte

- What are the standard aperture specifications of the electrolytic cell? Key Sizes for Your Electrochemical Setup

- What are the procedures for after using a double-layer water-bath electrolytic cell? Ensure Equipment Longevity and Data Accuracy