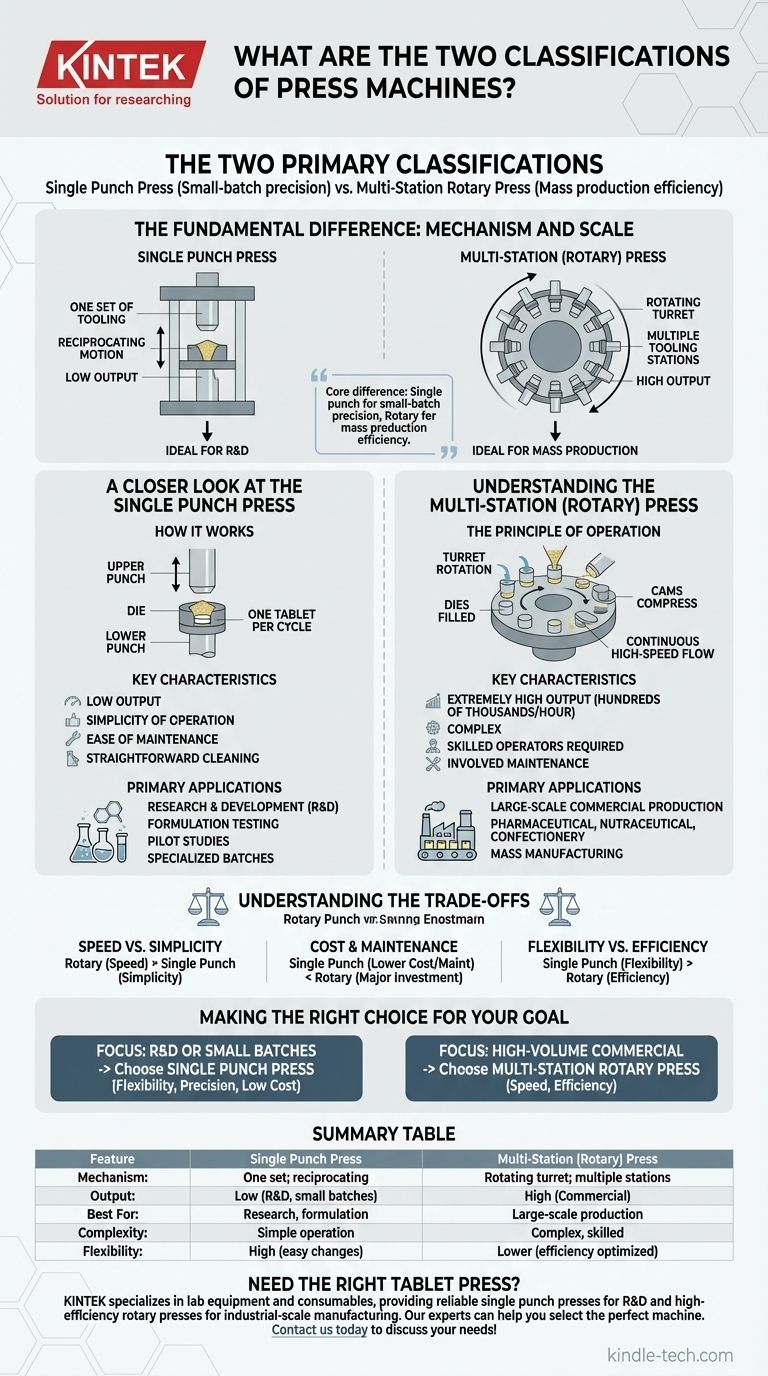

The two primary classifications for tablet press machines are the single punch press and the multi-station press, also known as a rotary press. These designs are fundamentally different, serving distinct purposes ranging from initial research and development to full-scale industrial production.

The core difference between a single punch and a rotary press is not just speed, but a fundamental distinction in mechanical design that dictates their application: single punch presses are for small-batch precision, while rotary presses are engineered for mass production efficiency.

The Fundamental Difference: Mechanism and Scale

The classification of tablet presses comes down to their core mechanical operation. This difference in design directly impacts their output capacity, complexity, and ideal use case.

A single punch press uses one set of tooling (a die and a pair of punches) to compress powder into a tablet one at a time. In contrast, a rotary press uses a rotating turret that holds numerous sets of tooling, allowing for the continuous production of many tablets simultaneously.

A Closer Look at the Single Punch Press

The single punch press is the foundational design, valued for its simplicity and precision in controlled environments.

How It Works

This machine operates with a single upper punch that descends into a die filled with powder, compressing it against a stationary lower punch. The process is a simple, reciprocating up-and-down motion, producing one tablet per cycle.

Key Characteristics

Its defining features are low output, simplicity of operation, and ease of maintenance. Because it uses only one set of tooling, setup and cleaning are straightforward.

Primary Applications

The single punch press is the standard for research and development (R&D) labs. It is ideal for testing new formulations, conducting pilot studies, and producing small, specialized batches where quality control on each tablet is paramount.

Understanding the Multi-Station (Rotary) Press

The rotary press is the workhorse of industrial tablet manufacturing, designed for unparalleled speed and volume.

The Principle of Operation

In a rotary press, a large circular turret holds many individual die and punch stations. As this turret rotates, the dies are filled with powder, and the punches are guided by cams to compress the tablets and then eject them in a continuous, high-speed flow.

Key Characteristics

This machine is defined by its extremely high output, capable of producing hundreds of thousands of tablets per hour. It is more complex, requiring skilled operators and more involved maintenance procedures.

Primary Applications

Rotary presses are essential for large-scale commercial production in the pharmaceutical, nutraceutical, and confectionery industries. Any application requiring mass manufacturing of tablets relies on this technology.

Understanding the Trade-offs

Choosing between these machines involves a clear evaluation of production goals against machine capabilities.

Speed vs. Simplicity

A rotary press offers unmatched production speed, making it the only viable option for commercial volume. A single punch press trades this speed for operational simplicity and is better suited for analysis than pure output.

Cost and Maintenance

The initial investment for a single punch press is significantly lower. Its simpler design also translates to lower maintenance costs and less required technical expertise to operate. A rotary press represents a major capital expenditure.

Flexibility vs. Efficiency

Single punch presses offer maximum flexibility. Changing tablet size, shape, or formulation is a relatively quick process, perfect for a lab environment. Rotary presses are models of efficiency, designed to run for long periods producing a single product with minimal variation.

Making the Right Choice for Your Goal

The correct machine is the one that aligns directly with your production scale and project objectives.

- If your primary focus is Research & Development or small pilot batches: The single punch press is the superior choice for its flexibility, precision, and low cost.

- If your primary focus is High-Volume Commercial Production: The multi-station rotary press is the only option that provides the necessary speed and efficiency for mass manufacturing.

Ultimately, understanding your operational scale is the key to selecting the right tablet compression technology.

Summary Table:

| Feature | Single Punch Press | Multi-Station (Rotary) Press |

|---|---|---|

| Mechanism | One set of tooling; reciprocating motion | Rotating turret with multiple tooling stations |

| Output | Low (ideal for R&D, small batches) | High (hundreds of thousands per hour) |

| Best For | Research, formulation testing, precision | Large-scale commercial production |

| Complexity | Simple operation, easy maintenance | Complex, requires skilled operation |

| Flexibility | High (easy to change tooling/formulation) | Lower (optimized for efficiency on one product) |

Need the right tablet press for your lab or production line? KINTEK specializes in lab equipment and consumables, providing reliable single punch presses for R&D and high-efficiency rotary presses for industrial-scale manufacturing. Our experts can help you select the perfect machine to enhance your productivity and precision. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What is the difference between a rotary tablet press and a single tablet punch press? A Guide to Choosing the Right Machine

- What is the principle of a single punch tablet press machine? A Guide to Precision Lab-Scale Production

- What is the use of a biomass pellet machine? Turn Waste into Fuel, Feed, and Bedding

- What is the working principle of pelletizing machine? Transform Powders into Dense, Uniform Pellets

- What is a press tab pill? The Complete Guide to Pressed Tablets

- What are pill presses used for? Transforming Powders into Precise Tablets for Medicine, Supplements, and More

- What is the process of pelleting biomass? Transform Raw Biomass into High-Value, Energy-Dense Fuel

- What is the difference between pelleting and pelletizing? Understand the Core Agglomeration Methods