In practice, the two most common and fundamental types of injection molding are defined by the class of polymer used: Thermoplastic Injection Molding and Thermoset Injection Molding. While numerous specialized techniques exist, these two processes form the foundation of plastic part manufacturing, differing primarily in how the material behaves when heated and cured.

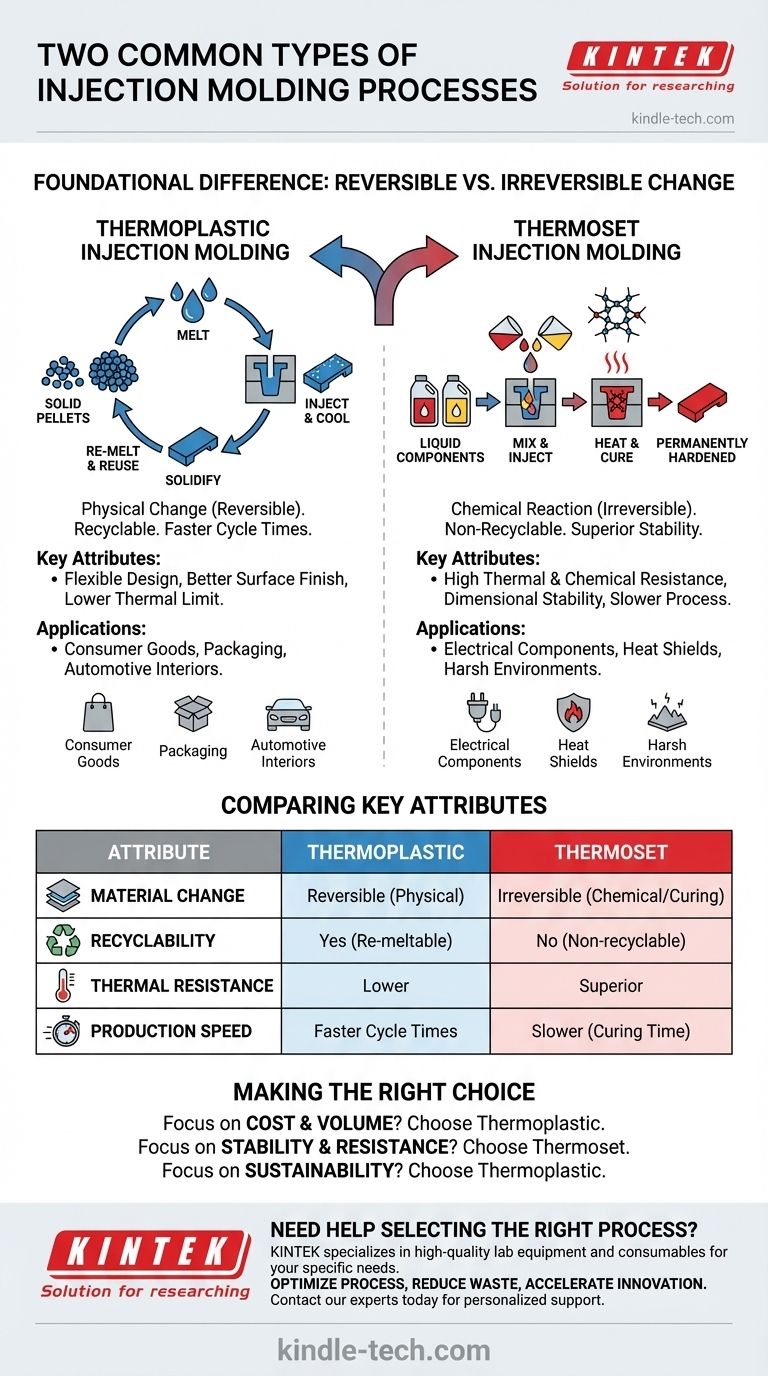

The core distinction is simple: thermoplastic molding involves a reversible physical change (melting and cooling), making the material recyclable, while thermoset molding involves an irreversible chemical reaction (curing), creating a more stable but non-recyclable part.

The Foundational Difference: Reversible vs. Irreversible Change

The choice between these two processes is one of the first and most critical decisions in product design. It hinges on the material's reaction to heat, which dictates the final part's properties, performance, and lifecycle.

What is Thermoplastic Injection Molding?

Thermoplastic injection molding is the most prevalent form of the technology. It uses plastic polymers that can be repeatedly melted and solidified without significant degradation.

The process is straightforward: solid plastic pellets are melted, injected under high pressure into a cooled mold, and then solidify into the desired shape.

Because this is a physical change, not a chemical one, the process is reversible. Scrap material and end-of-life parts can be ground up and reused, making it a more sustainable option.

What is Thermoset Injection Molding?

Thermoset molding uses polymers that start as liquids and are permanently hardened through a chemical reaction called curing.

In this process, two separate liquid components are often mixed before being injected into a heated mold. The heat initiates an irreversible cross-linking chemical reaction, curing the liquid into a rigid solid.

Once a thermoset part is cured, it cannot be melted again. Attempting to heat it will cause the material to char and degrade, not liquefy.

Comparing Key Attributes and Applications

The profound difference in material behavior leads to distinct advantages and use cases for each process.

Mechanical Strength and Dimensional Stability

Thermosets generally offer superior dimensional stability and structural integrity, especially under load and at high temperatures, due to their rigid, cross-linked molecular structure.

Thermal and Chemical Resistance

This is the primary advantage of thermosets. Their cured structure makes them highly resistant to heat, corrosion, and chemical attack, making them ideal for harsh environments.

Surface Finish and Design Flexibility

Thermoplastics often provide a better surface finish straight from the mold and allow for greater flexibility in design, including features like living hinges. They are available in a vast array of colors and clarities.

Production Speed and Cost

Thermoplastic molding typically has faster cycle times. The process only requires the material to cool and solidify, whereas thermosets must remain in the mold long enough for the chemical reaction to complete.

Understanding the Trade-offs

Neither process is universally superior; the correct choice depends entirely on the application's demands and constraints.

The Irreversibility of Thermosets

The inability to re-melt thermosets is their greatest strength and weakness. It provides incredible stability but means that scrap material from production cannot be reused, and the final parts are not recyclable.

The Temperature Sensitivity of Thermoplastics

The re-meltable nature of thermoplastics makes them versatile and recyclable. However, this also means they have a lower maximum service temperature and can deform if exposed to conditions beyond their thermal limits.

Specialized Process Variations

Beyond these two foundational types, many specialized techniques exist. Processes like Overmolding (molding one plastic over another) or Metal Injection Molding (using metal powders with a binder) are advanced methods used to achieve specific product requirements, but they still operate on similar core principles of injection and solidification.

Making the Right Choice for Your Goal

Selecting the correct process requires aligning your product's primary requirements with the fundamental strengths of the material.

- If your primary focus is cost-effective, high-volume production with design flexibility: Thermoplastic injection molding is the default choice for consumer goods, packaging, and automotive interiors.

- If your primary focus is maximum thermal stability and chemical resistance: Thermoset injection molding is essential for electrical components, heat shields, and parts exposed to harsh industrial environments.

- If your primary focus is sustainability and recyclability: Thermoplastic injection molding is the only viable option between the two.

Understanding the fundamental difference between these processes empowers you to make an informed decision that ensures your part performs as intended.

Summary Table:

| Attribute | Thermoplastic Injection Molding | Thermoset Injection Molding |

|---|---|---|

| Material Change | Reversible (Physical) | Irreversible (Chemical/Curing) |

| Recyclability | Yes (Re-meltable) | No (Non-recyclable) |

| Thermal Resistance | Lower | Superior |

| Primary Applications | Consumer Goods, Automotive Interiors | Electrical Components, Heat Shields |

| Production Speed | Faster Cycle Times | Slower (Due to Curing Time) |

Need Help Selecting the Right Molding Process for Your Lab or Production Needs?

Choosing between thermoplastic and thermoset injection molding is critical for achieving the desired part performance, cost-efficiency, and sustainability. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific requirements. Whether you're prototyping, testing materials, or scaling production, our expertise ensures you have the right tools to succeed.

Let us help you:

- Optimize your process with reliable equipment designed for precision and durability.

- Reduce waste and costs by selecting the ideal materials and methods for your application.

- Accelerate innovation with solutions that support both thermoplastic and thermoset workflows.

Ready to enhance your injection molding outcomes? Contact our experts today for personalized support and discover how KINTEK can empower your laboratory's success!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Lab Infrared Press Mold

People Also Ask

- What is injection molding in simple words? A Simple Guide to Mass-Producing Parts

- What is a vulcanizing press? Essential Tool for Rubber Manufacturing and Tire Production

- What is the difference between monolayer and multilayer film? Choose the Right Packaging for Your Product

- What does a two roll mill machine do? Master Polymer & Rubber Compounding

- What is the internal structure of a mixer? A Guide to Core Components and Operation

- What is the raw material for blown film extrusion? Selecting the Right Polyethylene for Your Film

- What is the principle of calendering? Enhance Fabric Surface with Heat and Pressure

- What is twin screw granulation? A Guide to Modern, Continuous Pharmaceutical Manufacturing