In essence, ceramic tubes are specialized components used in applications where extreme conditions would cause most other materials, like metals or plastics, to fail. They are primarily found in high-temperature furnaces, high-voltage electrical systems, and equipment handling corrosive or abrasive materials due to their unique combination of thermal, electrical, and chemical resistance.

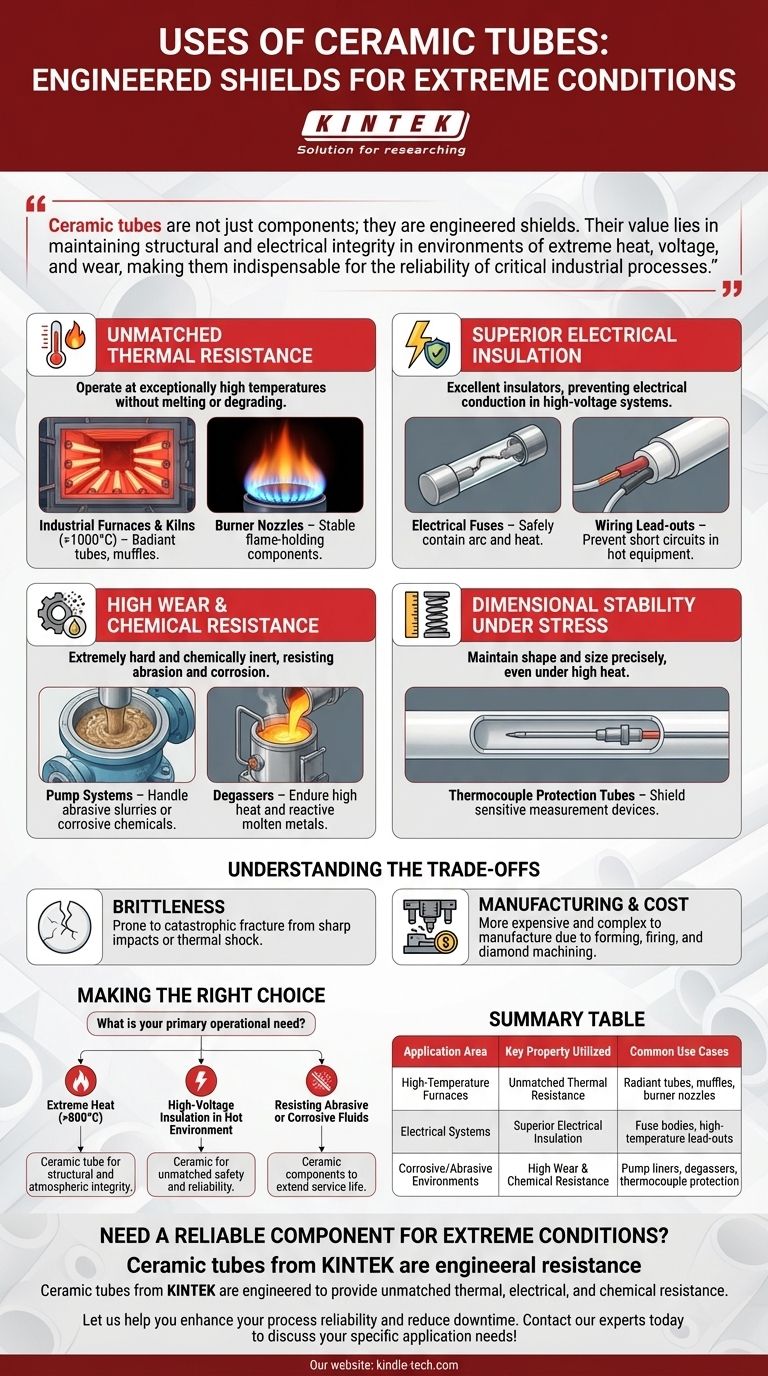

Ceramic tubes are not just components; they are engineered shields. Their value lies in maintaining structural and electrical integrity in environments of extreme heat, voltage, and wear, making them indispensable for the reliability of critical industrial processes.

The Core Properties Driving Ceramic Tube Use

The selection of a ceramic tube is almost always driven by its ability to withstand one or more extreme environmental factors. Understanding these core properties is key to understanding their applications.

Unmatched Thermal Resistance

Ceramic materials can operate at exceptionally high temperatures without melting, deforming, or degrading. This makes them the default choice for thermal processing applications.

You will find them used as radiant tubes, muffles, and structural components inside industrial furnaces and kilns, where temperatures can easily exceed 1000°C (1832°F).

They are also used as burner nozzles and flame-holding tubes in gas and oil-fired systems, providing a stable and durable component directly in the path of the flame.

Superior Electrical Insulation

Most ceramics are excellent electrical insulators, meaning they do not conduct electricity. This property is critical for safety and function in high-voltage equipment.

Ceramic tubes are commonly used as the body for electrical fuses, safely containing the arc and heat generated when a fuse blows.

They also serve as insulating lead-outs for electrical wiring in high-temperature equipment like heaters and furnaces, preventing short circuits where plastic or rubber insulation would melt.

High Wear and Chemical Resistance

Ceramics are extremely hard and chemically inert, allowing them to resist both mechanical wear (abrasion) and chemical attack (corrosion).

In pump systems, ceramic tubes or liners are used to handle abrasive slurries or corrosive chemicals that would quickly erode metal components.

They are also used in equipment like degassers, where they must endure both high temperatures and contact with reactive molten metals without degrading.

Dimensional Stability Under Stress

Unlike metals that expand significantly with heat, ceramics maintain their shape and size with high precision.

This stability is vital for applications like thermocouple protection tubes. The ceramic tube shields the sensitive temperature measurement device from the harsh environment without distorting the reading or degrading.

Understanding the Trade-offs

While incredibly capable, ceramic tubes are not a universal solution. Their unique properties come with important limitations that must be considered during design.

The Challenge of Brittleness

The primary trade-off for ceramics is brittleness. While they can be very strong and resist impact, they do not bend or deform like metals.

A sufficiently sharp impact or high thermal shock can cause a ceramic tube to fracture catastrophically without warning. This requires careful handling during installation and consideration of mechanical and thermal stresses during operation.

Manufacturing and Cost Considerations

Ceramics are harder to manufacture into complex shapes than metals or plastics. The processes of forming and firing are energy-intensive, and final machining requires specialized diamond tooling.

This complexity generally makes ceramic tubes more expensive than their metal counterparts, reserving their use for applications where their unique properties are an absolute necessity.

Making the Right Choice for Your Application

Your decision to use a ceramic tube should be based on a clear operational need that other materials cannot meet.

- If your primary focus is extreme heat (>800°C): A ceramic tube is often the only viable choice for long-term structural and atmospheric integrity in furnaces and kilns.

- If your primary focus is high-voltage insulation in a hot environment: Ceramic provides a level of safety and reliability that polymeric insulators cannot match.

- If your primary focus is resisting abrasive or corrosive fluids: Ceramic components in pumps and fluid systems can dramatically extend service life and reduce maintenance downtime.

By understanding these fundamental properties and trade-offs, you can confidently determine where a ceramic tube is the optimal engineering solution.

Summary Table:

| Application Area | Key Property Utilized | Common Use Cases |

|---|---|---|

| High-Temperature Furnaces | Unmatched Thermal Resistance | Radiant tubes, muffles, burner nozzles |

| Electrical Systems | Superior Electrical Insulation | Fuse bodies, high-temperature lead-outs |

| Corrosive/Abrasive Environments | High Wear & Chemical Resistance | Pump liners, degassers, thermocouple protection |

Need a reliable component for extreme conditions?

Ceramic tubes from KINTEK are engineered to provide unmatched thermal, electrical, and chemical resistance, ensuring the longevity and reliability of your critical laboratory and industrial equipment. Whether you're operating a high-temperature furnace, designing a high-voltage system, or handling corrosive materials, our expertise in lab equipment and consumables can provide the optimal solution.

Let us help you enhance your process reliability and reduce downtime. Contact our experts today to discuss your specific application needs!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- Why is a high-purity alumina lining required for high-temperature tube furnaces? Ensure Accurate Biomass Research