In short, Silicon Carbide (SiC) ceramics are used wherever extreme performance is non-negotiable. Their unique combination of hardness, heat resistance, and thermal conductivity makes them essential in industries like semiconductor manufacturing, aerospace, defense, and high-temperature industrial processing for components that other materials simply cannot handle.

The true value of Silicon Carbide isn't just one single property, but its rare ability to combine near-diamond hardness with exceptional stability at high temperatures and an ability to manage heat effectively. This trifecta makes it a go-to material for solving the most demanding engineering challenges.

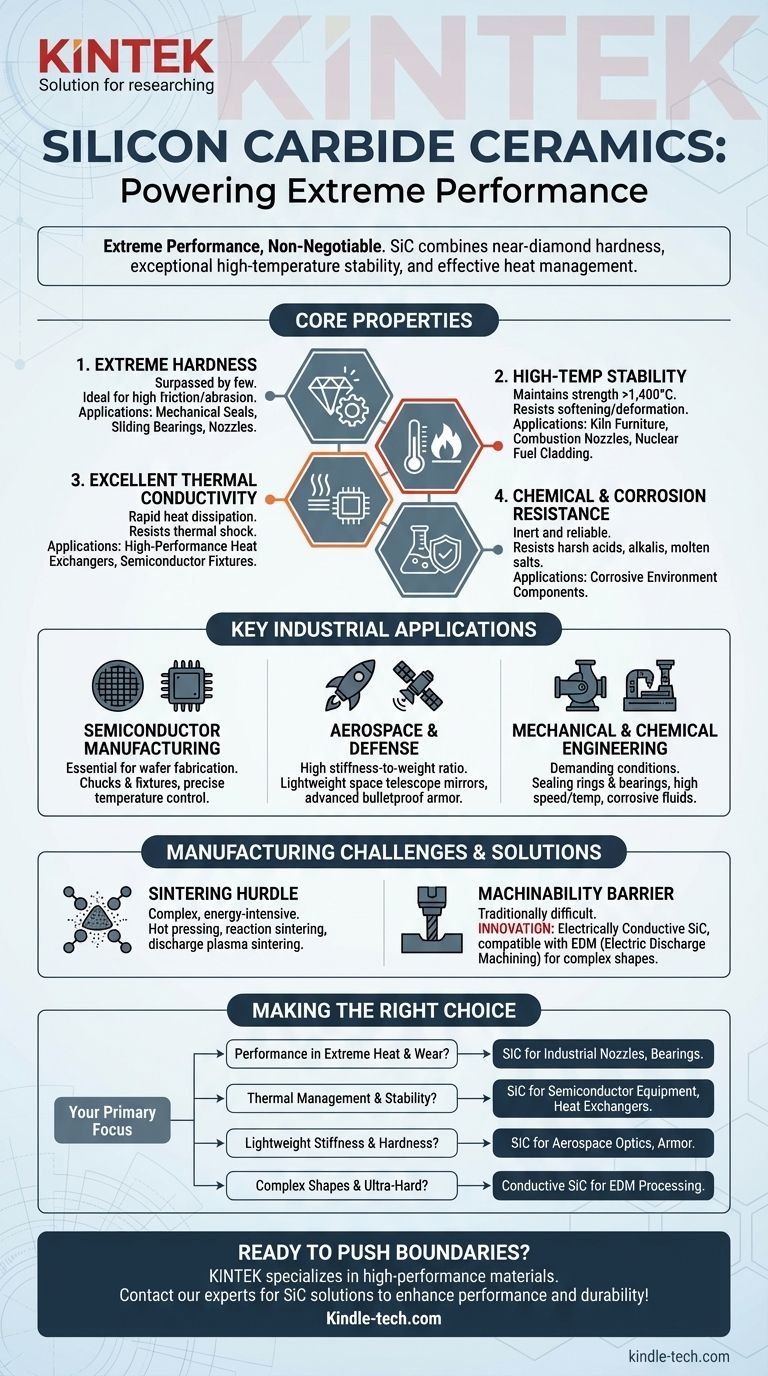

The Core Properties Driving SiC Adoption

To understand where Silicon Carbide is used, you must first understand the fundamental properties that make it so valuable. Its applications are a direct result of its extreme material characteristics.

### Extreme Hardness and Wear Resistance

Silicon Carbide is one of the hardest commercially available materials, surpassed only by a few substances like diamond. This property is directly responsible for its use in applications involving high friction and abrasion.

This makes it ideal for components like mechanical sealing rings, sliding bearings, and nozzles that must maintain their precise shape while enduring constant wear.

### High-Temperature Stability

Unlike metals that weaken or melt, SiC maintains exceptional mechanical strength at temperatures well over 1,400°C. It does not soften or deform easily under thermal stress.

This stability is why it is used for kiln furniture (shelves and supports inside industrial furnaces), combustion nozzles, and as a potential cladding material for nuclear fuel.

### Excellent Thermal Conductivity

While being an electrical insulator in its pure form, SiC conducts heat exceptionally well. This allows it to dissipate heat rapidly and resist thermal shock—sudden, extreme temperature changes that would crack other ceramics.

This characteristic is critical for high-performance heat exchangers and for fixture materials used in semiconductor wafer preparation, where precise temperature control is paramount.

### Chemical and Corrosion Resistance

Silicon Carbide is highly inert and resists corrosion from most strong acids, alkalis, and molten salts. It provides a stable and reliable solution for components operating in harsh chemical environments.

Key Industrial Applications in Detail

The unique properties of SiC translate directly into critical roles across several advanced industries.

### Semiconductor Manufacturing

SiC is essential in the fabrication of silicon wafers. Its stiffness, thermal stability, and conductivity make it the perfect material for chucks and fixtures that hold wafers during high-temperature etching and deposition processes, ensuring flatness and precise temperature control.

### Aerospace and Defense

The material's high stiffness-to-weight ratio is a significant advantage. This has led to its use in creating large, lightweight space telescope mirrors that remain stable across wide temperature fluctuations.

Its extreme hardness also makes it a primary component in advanced bulletproof armor and ceramic armor systems for vehicles.

### Mechanical and Chemical Engineering

In pumps and industrial equipment, sealing rings and bearings made of SiC can operate in more demanding conditions—higher speeds, temperatures, and more corrosive fluids—than those made from traditional steel or other ceramics.

Understanding the Primary Challenge: Manufacturing

While its properties are exceptional, the very hardness that makes SiC so useful also makes it incredibly difficult and costly to manufacture into final parts.

### The Sintering Hurdle

Turning SiC powder into a solid, dense component is a complex process. It requires specialized, energy-intensive techniques like hot pressing, reaction sintering, or discharge plasma sintering to bond the particles together without degrading the material.

### The Machinability Barrier

Traditionally machining SiC is nearly impossible due to its hardness. This has historically limited its use to simpler shapes.

However, a key innovation is the creation of electrically conductive SiC ceramics. By controlling its resistivity, the material can be precisely shaped using Electric Discharge Machining (EDM), enabling the creation of large or complex components with high accuracy.

Making the Right Choice for Your Goal

Selecting SiC is a decision to prioritize ultimate performance over cost and manufacturing simplicity.

- If your primary focus is performance in extreme heat and wear: SiC is a leading choice for components like industrial nozzles, bearings, or kiln supports.

- If your primary focus is thermal management and stability: It is the ideal material for semiconductor processing equipment and advanced heat exchangers.

- If your primary focus is lightweight stiffness and hardness: SiC is a top-tier option for aerospace optics and advanced armor applications.

- If your primary focus is creating complex shapes from an ultra-hard ceramic: You must investigate conductive SiC grades compatible with EDM processing.

Ultimately, silicon carbide is an enabling material, pushing the boundaries of what is possible in the most demanding technological fields.

Summary Table:

| Property | Benefit | Key Applications |

|---|---|---|

| Extreme Hardness | Superior wear resistance | Mechanical seals, bearings, armor |

| High-Temperature Stability | Maintains strength >1,400°C | Kiln furniture, combustion nozzles |

| Excellent Thermal Conductivity | Rapid heat dissipation, thermal shock resistance | Semiconductor fixtures, heat exchangers |

| Chemical Resistance | Withstands harsh acids and alkalis | Corrosive environment components |

Ready to push the boundaries of your applications with silicon carbide ceramics? KINTEK specializes in high-performance lab equipment and consumables, delivering the advanced materials and expertise needed for semiconductor, aerospace, and industrial challenges. Contact our experts today to discuss how SiC solutions can enhance your performance and durability!

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Zinc Selenide ZnSe Optical Window Glass Substrate Wafer and Lens

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- Assemble Square Lab Press Mold for Laboratory Applications

People Also Ask

- What are 4 disadvantages of brazing? Understanding the Critical Limitations of This Joining Method

- What are the disadvantages of brazing? Understanding the key limitations and trade-offs.

- What are ceramic tubes used for? Essential for Extreme Heat, Insulation & Purity

- What is a ceramic tube? A Guide to Extreme Environment Performance

- What is the function of the ceramic tube in a DBD plasma jet? Enhancing Stability for Delicate Material Treatment