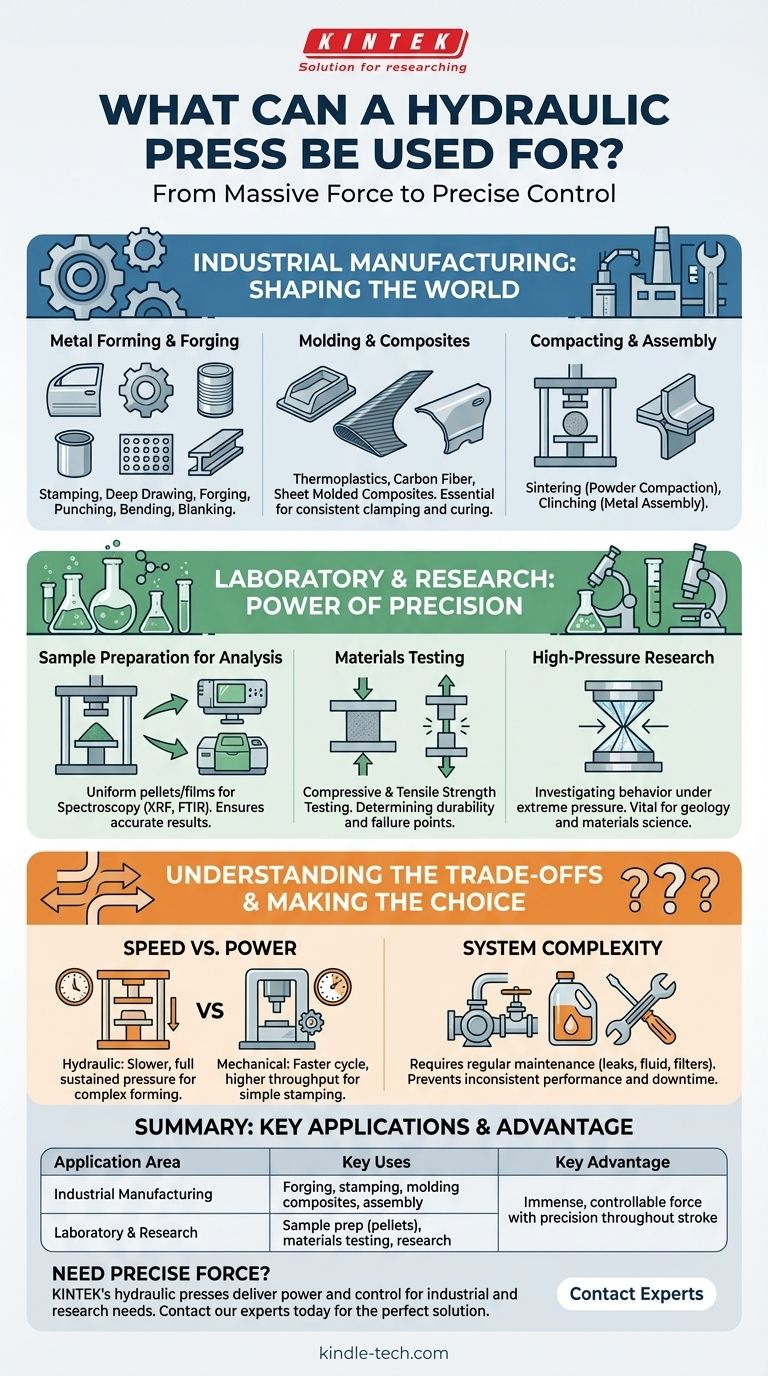

At its core, a hydraulic press is used for any task requiring immense and controllable force. Its applications span from massive industrial operations like forging metal and molding automotive parts to precise laboratory tasks like preparing samples for chemical analysis.

The true value of a hydraulic press lies not just in its ability to generate massive force, but in its capacity to apply that force with incredible precision and consistency throughout its entire stroke. This combination of power and control is why it is indispensable across so many different fields.

Industrial Manufacturing: Shaping the Modern World

The most common applications for hydraulic presses are in heavy industry, where raw materials are shaped, formed, and assembled into finished goods.

Metal Forming and Forging

A primary use is manipulating metal. The sustained pressure is perfect for tasks like stamping flat sheets into car doors, deep drawing metal into cans, and forging raw billets into high-strength components.

Other metalworking applications include punching holes, bending structural steel, and blanking out parts from sheet stock.

Molding and Composites

Hydraulic presses are essential for forming materials that require both heat and pressure. This includes creating thermoplastic components, carbon fiber parts for aerospace, and sheet molded composites (SMC) for automotive bodies.

The press provides the consistent clamping force needed for these materials to cure properly and achieve their desired structural properties.

Compacting and Assembly

These presses are also used to compact powders into solid forms, from pharmaceuticals to metallic components in a process called sintering.

In assembly operations, a technique called clinching uses the press to lock two pieces of metal together without the need for welding or fasteners.

Laboratory and Research: The Power of Precision

On a much smaller scale, hydraulic presses are a cornerstone of scientific research and quality control, where precision is paramount.

Sample Preparation for Analysis

In spectroscopy (like XRF and FTIR), samples must be uniform to yield accurate results. A lab press compresses powdered material into a dense, homogenous pellet or thin film, which is ideal for analysis.

This process eliminates inconsistencies in the sample, ensuring that analytical instruments provide reliable data.

Materials Testing

Engineers and scientists use hydraulic presses to test the limits of materials. This includes compressive strength testing (crushing a sample) and tension testing (pulling a sample apart) to determine durability and failure points.

High-Pressure Research

The press is a critical tool for investigating how different substances behave under extreme pressure. This research is vital for fields ranging from geology to materials science.

Understanding the Trade-offs

While incredibly versatile, hydraulic presses are not the solution for every problem. Understanding their limitations is key.

Speed vs. Power

Hydraulic presses are generally slower than their mechanical counterparts. The movement of hydraulic fluid to build pressure takes more time than a simple flywheel and crank mechanism.

For high-speed, repetitive stamping operations, a mechanical press is often a better choice.

System Complexity

Hydraulic systems involve pumps, valves, seals, and fluid. They require regular maintenance to prevent leaks, manage fluid temperature, and ensure the system remains free of contaminants.

Failure to maintain the hydraulic system can lead to inconsistent performance and costly downtime.

Making the Right Choice for Your Goal

Selecting the right tool depends entirely on the specific requirements of your task.

- If your primary focus is forming complex shapes or composite materials: The full, sustained pressure of a hydraulic press throughout its stroke is essential for a quality result.

- If your primary focus is high-speed, repeatable stamping of simple parts: A mechanical press may offer a faster cycle time and higher throughput.

- If your primary focus is precise sample preparation or materials testing: A laboratory hydraulic press is the industry standard, offering unparalleled control and repeatability.

Ultimately, the hydraulic press is a foundational tool for converting force into tangible results with precision and control.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Industrial Manufacturing | Metal forging, stamping, deep drawing, molding composites (carbon fiber, SMC), powder compacting, assembly. |

| Laboratory & Research | Sample preparation (pellets for XRF/FTIR), materials testing (compressive/tensile strength), high-pressure research. |

| Key Advantage | Combines immense, controllable force with precision and consistency throughout the entire stroke. |

Need precise force for your application? Whether you're forging metal components or preparing uniform samples for laboratory analysis, KINTEK's hydraulic presses deliver the power and control you require. Our lab equipment is engineered for reliability and precision, serving the diverse needs of industrial manufacturing and scientific research. Contact our experts today to find the perfect hydraulic press solution for your goals.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is an industrial press used for? Shape, Cut, and Assemble with Precision Force

- What is the minimum detection limit for XRF? Achieve Accurate Trace Element Analysis

- How is a laboratory hydraulic press utilized in double-layer solid-state battery assembly? Key Pre-pressing Guide

- What is alternative for hydraulic press? Find the Right Press for Your Application

- How many tons can a hydraulic press hold? Understanding Safe vs. Maximum Capacity

- What can KBr be used as? The Essential Matrix for Accurate FTIR Spectroscopy

- What is the primary function of a laboratory hydraulic press in TiO2 PLD target prep? Form High-Density Green Bodies

- What are the features of a hydraulic press? Unlock Immense Force with Simple, Reliable Design