In essence, a lab muffle furnace is a high-temperature oven that provides an exceptionally clean and controlled environment for heating materials. Its defining feature is the "muffle," an internal chamber that isolates the sample from the direct heat source and any byproducts of combustion. This separation ensures that the material is heated purely without the risk of cross-contamination, making it indispensable for processes where sample integrity is paramount.

The true value of a muffle furnace isn't just its ability to reach extreme temperatures, but its capacity to do so while completely isolating the sample. This guarantees that any changes observed are a result of the heat alone, not from reactions with external contaminants.

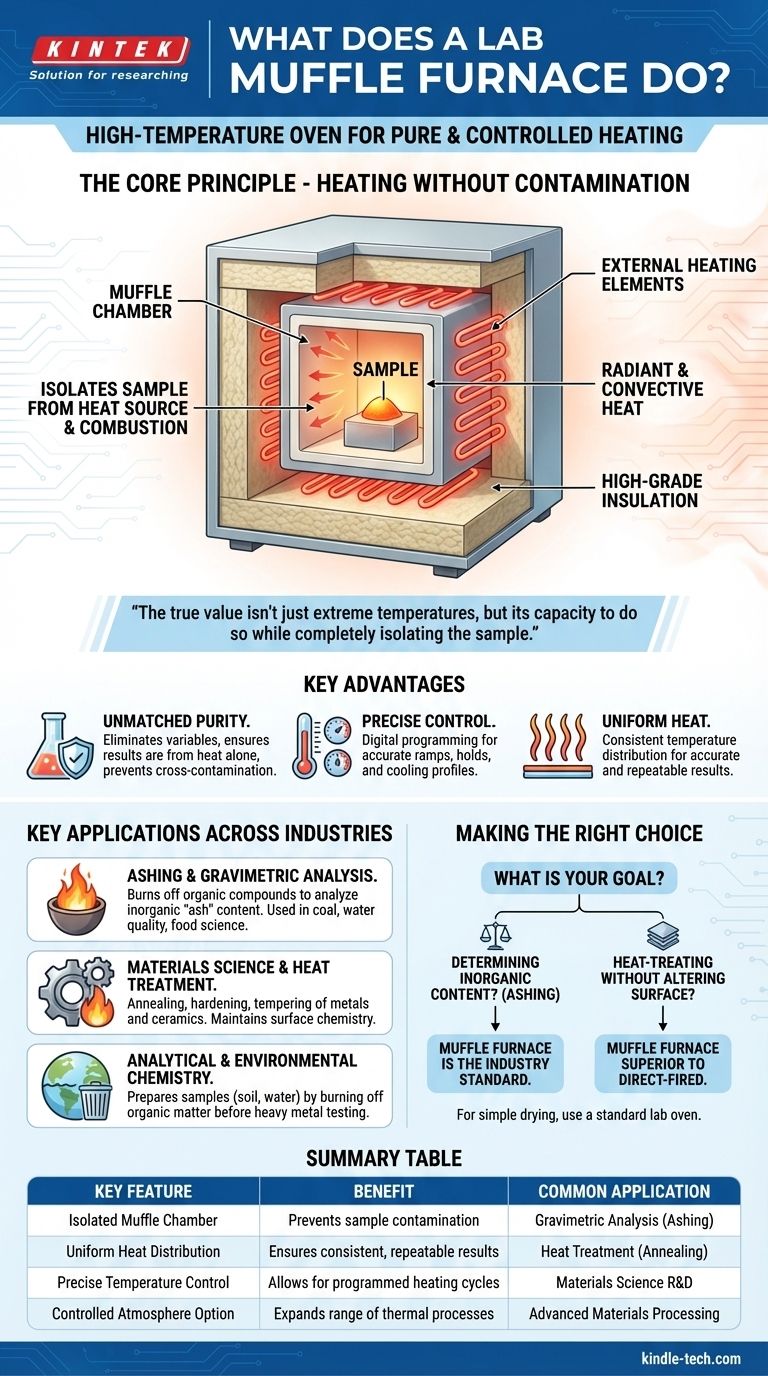

The Core Principle: Heating Without Contamination

A muffle furnace's design is elegantly simple and focused on one goal: purity. Unlike a conventional oven or kiln where combustion gases might interact with the material, the muffle acts as a perfect barrier.

How the "Muffle" Works

The muffle is a sealed internal chamber, typically made of a high-temperature ceramic. This chamber contains the sample.

Heating elements are wrapped around the outside of the muffle. This design ensures that heat radiates inward, but no part of the heating element or surrounding atmosphere can touch the sample.

Layers of high-grade insulation surround the entire assembly, minimizing heat loss and allowing the furnace to maintain extremely high and stable temperatures efficiently.

Achieving Uniform Heat

The furnace relies on thermal radiation and thermal convection to heat the air inside the sealed chamber.

This method allows for remarkably uniform heat distribution, ensuring that the entire sample is exposed to the same temperature. This consistency is critical for obtaining accurate and repeatable results.

Creating Controlled Atmospheres

While many processes use the air trapped inside the chamber, some advanced muffle furnaces allow for the introduction of specific gases.

By purging the chamber and introducing nitrogen, hydrogen, or other gases, a specific, non-reactive or reactive atmosphere can be created. This further expands the range of possible thermal processes.

Key Applications Across Industries

The muffle furnace's unique capability makes it a cornerstone tool in numerous scientific and industrial fields. Its applications almost always revolve around the need for high heat combined with high purity.

Ashing and Gravimetric Analysis

This is the most common use. A sample is heated to a temperature that completely burns off all organic compounds.

The remaining inorganic material, known as ash, is then weighed. This process is fundamental in coal analysis (for ash content), water quality testing, and food science to determine mineral content.

Materials Science and Heat Treatment

Muffle furnaces are used for processes like annealing, hardening, and tempering metals and ceramics.

Because the process is free from contaminants, the surface chemistry of the material is not altered, which is critical for developing advanced materials, semiconductors, and electronic components.

Analytical and Environmental Chemistry

For many types of analysis, samples must be prepared by removing interfering substances.

A muffle furnace can be used to process soil, water, or other environmental samples to burn off organic matter before testing for heavy metals or other inorganic pollutants.

Understanding the Key Advantages

While powerful, a muffle furnace is a specific tool for a specific job. Understanding its core benefits helps clarify when it is the right choice.

Advantage: Unmatched Purity

The isolation of the sample is the furnace's single greatest strength. It eliminates variables and ensures that results are a direct consequence of the thermal process you designed.

Advantage: Precise Temperature Control

Modern muffle furnaces offer highly accurate digital controls. This allows you to program specific temperature ramps, holds (soaks), and cooling profiles, which is essential for repeatable scientific experiments and quality control.

Advantage: Robustness and Efficiency

The simple, robust design with heavy insulation leads to a long service life and high energy efficiency. They are built to withstand constant high-heat cycles for years.

Limitation: Processing Speed

The same heavy insulation that makes a muffle furnace efficient also means it has significant thermal mass. It takes time to heat up to the target temperature and, more importantly, a long time to cool down safely. It is not suited for rapid thermal cycling.

Making the Right Choice for Your Goal

Whether a muffle furnace is the correct instrument depends entirely on your analytical or processing objective.

- If your primary focus is determining inorganic content (ashing): The muffle furnace is the industry-standard tool designed specifically for this purpose.

- If your primary focus is heat-treating a material without altering its surface chemistry: Its isolated chamber makes it vastly superior to direct-fired furnaces.

- If your primary focus is simply drying a sample at moderate temperatures: A standard laboratory oven is a faster, more efficient, and more practical choice.

- If your primary focus is sample preparation for trace element analysis: The muffle furnace provides the clean burn-off needed to ensure your downstream measurements are accurate.

By isolating your sample from everything but pure, controlled heat, the muffle furnace empowers you to achieve the most accurate and reliable high-temperature results.

Summary Table:

| Key Feature | Benefit | Common Application |

|---|---|---|

| Isolated Muffle Chamber | Prevents sample contamination | Gravimetric Analysis (Ashing) |

| Uniform Heat Distribution | Ensures consistent, repeatable results | Heat Treatment (Annealing) |

| Precise Temperature Control | Allows for programmed heating cycles | Materials Science R&D |

| Controlled Atmosphere Option | Expands range of thermal processes | Advanced Materials Processing |

Ready to ensure the purity and accuracy of your high-temperature processes?

KINTEK specializes in providing robust and precise lab equipment, including muffle furnaces, to meet the demanding needs of laboratories. Whether you are working in materials science, environmental testing, or quality control, our solutions are designed to deliver contamination-free heating and reliable results.

Contact us today to find the perfect muffle furnace for your specific application and enhance your lab's capabilities!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the importance of melting process? Master the Foundation of Metal Production

- Why is the melting point different for different substances? The Key Role of Bond Strength

- How to cool a muffle furnace? Ensure Safety and Maximize Equipment Lifespan

- How is melting point affected by heating rate? Avoid Inaccurate Measurements in Your Lab

- Why is ceramic used in making furnace? Achieve Superior Heat Resistance and Efficiency