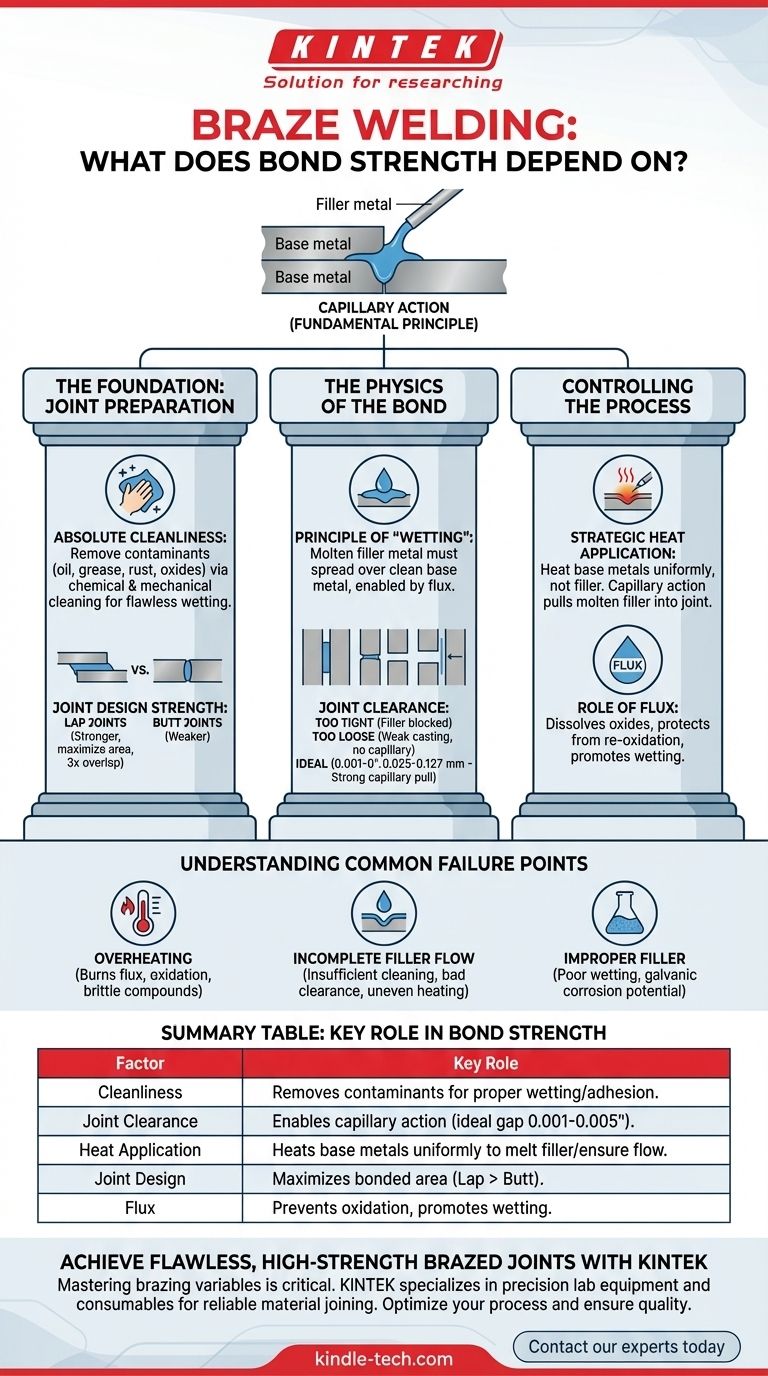

In braze welding, bond strength depends fundamentally on capillary action, which is governed by three critical factors: the cleanliness of the base metals, the clearance (gap) between the parts, and the correct application of heat. Unlike traditional welding, braze welding does not melt the base metals; its strength comes from a metallurgical bond formed when a filler metal adheres to a large, clean surface area.

The ultimate strength of a brazed joint is not determined by the strength of the filler metal alone, but by the design of the joint and the perfection of the bonding process. A strong braze is the result of maximizing the bonded surface area and ensuring that surface is flawlessly wetted by the filler metal.

The Foundation: Joint Preparation

The vast majority of braze welding failures can be traced back to inadequate preparation. The metallurgical bond at the heart of the process cannot form if the surfaces are not pristine and properly configured.

The Absolute Necessity of Cleanliness

Contaminants like oil, grease, rust, and oxides act as a physical barrier, preventing the molten filler metal from making intimate contact with the base metal. This prevents the bond from forming.

Cleaning is a two-step process: chemical cleaning (using degreasers or solvents to remove oils) followed by mechanical cleaning (using a wire brush, sandpaper, or grinding to remove oxides). The surface should be clean and bright right before assembly.

Strength Through Joint Design

Since the base metal is not melted, the strength of the joint is a function of the total bonded surface area.

Lap joints are inherently stronger than butt joints in brazing. A good rule of thumb is to design the lap length to be at least three times the thickness of the thinnest base metal member. This design ensures that the joint will be stronger than the base metals themselves.

The Physics of the Bond: Capillary Action

Capillary action is the phenomenon that draws the molten filler metal into the tight gap between the two base metal parts, distributing it completely throughout the joint. For this to work, two conditions must be met.

The Principle of "Wetting"

Wetting is the ability of a liquid to spread over a solid surface. Think of water beading up on a waxed car hood (poor wetting) versus spreading out on a clean glass pane (good wetting).

For a strong bond, the molten filler metal must "wet" the base metal. This only happens on a perfectly clean, oxide-free surface, which is where flux plays its essential role.

The "Goldilocks" Rule of Joint Clearance

The gap between the parts is the single most critical parameter for achieving maximum strength.

- Too tight: If the clearance is too small, the filler metal cannot flow into the joint.

- Too loose: If the gap is too wide, capillary action is lost. The joint will be filled with filler metal, but it will essentially be a weak casting with very little joint strength.

For most common filler metals, the ideal clearance is between 0.001 and 0.005 inches (0.025 to 0.127 mm). This tiny gap creates the powerful capillary force needed to pull the filler into the entire joint.

Controlling the Process: Heat, Flux, and Filler

With a clean, properly designed joint, success now depends on execution. The goal is to bring the entire joint assembly to the brazing temperature uniformly.

The Role of Flux

Flux is a chemical compound that serves three purposes:

- It dissolves and removes any residual oxides on the base metal.

- It protects the part from re-oxidizing as it is heated.

- It promotes the wetting action of the filler metal, helping it flow smoothly.

The flux melting can also serve as a useful temperature indicator that the base metal is approaching the brazing temperature.

Strategic Heat Application

A common mistake is to heat the filler metal directly. The correct technique is to heat the base metals.

The heat should be applied broadly and evenly to the entire joint area. When the base metals reach the working temperature of the filler metal, they will melt it on contact. Capillary action will then pull this molten filler into the joint, regardless of gravity.

Understanding Common Failure Points

A deep understanding of why joints fail is crucial for ensuring they succeed. Trust in a brazed joint comes from knowing you've avoided these common pitfalls.

Overheating: The Silent Strength Killer

Applying too much heat is just as bad as too little. Overheating can burn away the flux, leading to heavy oxidation that stops the filler flow. It can also cause the filler metal to excessively alloy with the base metal, creating brittle intermetallic compounds that drastically reduce the joint's ductility and strength.

Incomplete Filler Flow

If you disassemble a failed joint and see areas that are not covered in filler metal, it points to a process failure. The cause is almost always one of three things: insufficient cleaning, improper joint clearance, or uneven heating that created cold spots.

Improper Filler Metal Selection

The filler metal must be chemically compatible with the base metals you are joining. Using the wrong filler can result in poor wetting, a weak bond, or even create a potential for galvanic corrosion in the finished assembly, especially when joining dissimilar metals.

Making the Right Choice for Your Goal

To translate these principles into practice, tailor your approach to the specific requirements of your joint.

- If your primary focus is maximum tensile and shear strength: Design a lap joint with an overlap of at least 3x the thinnest metal's thickness and maintain a precise, tight clearance.

- If your primary focus is joining dissimilar metals (e.g., copper to steel): Prioritize selecting a filler metal and flux system specifically designed for that combination to ensure chemical compatibility and proper wetting.

- If you are experiencing inconsistent results or failures: Immediately re-evaluate your cleaning protocol and heat control. Most problems are solved by being more meticulous in preparation and ensuring the entire joint is heated evenly.

A successful braze weld is the direct result of a carefully controlled process that prioritizes cleanliness, precision, and a fundamental understanding of how the materials interact.

Summary Table:

| Factor | Key Role in Bond Strength |

|---|---|

| Cleanliness | Removes contaminants for proper filler metal wetting and adhesion. |

| Joint Clearance | Enables capillary action; ideal gap is 0.001-0.005 inches. |

| Heat Application | Heats base metals uniformly to melt filler metal and ensure complete flow. |

| Joint Design | Maximizes bonded surface area; lap joints are stronger than butt joints. |

| Flux | Prevents oxidation and promotes wetting for a flawless bond. |

Achieve Flawless, High-Strength Brazed Joints with KINTEK

Mastering the variables of braze welding is critical for joint integrity. Whether you're joining dissimilar metals or requiring maximum tensile strength, the right equipment and consumables are essential for repeatable success.

KINTEK specializes in precision lab equipment and consumables for material joining applications. We provide the reliable tools and expert support your laboratory needs to ensure every braze weld meets the highest standards of strength and quality.

Let us help you optimize your brazing process. Contact our experts today to discuss your specific application requirements.

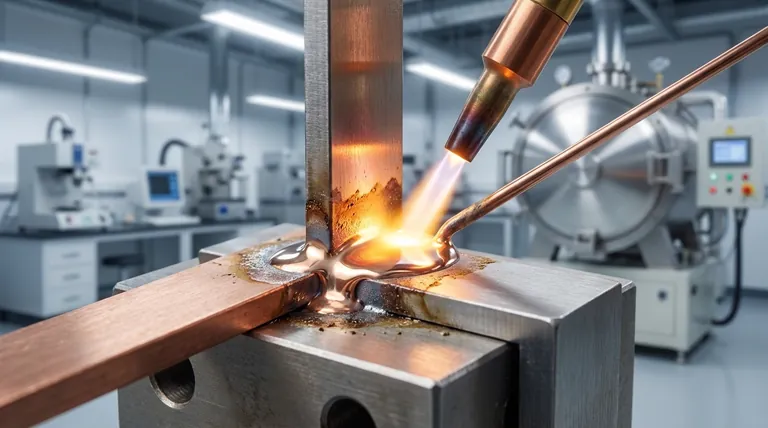

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production

- Why is precise temperature control necessary for SiC/Cu Vacuum Hot Pressing? Mastering the Cu9Si Interface Phase

- Why is a vacuum essential for sintering metal-ceramic composites? Achieve Pure, High-Density Results