At its core, hot isostatic pressing (HIP) is a manufacturing process that uses high temperature and uniform, gas-based pressure to eliminate internal defects in metals and ceramics. It densifies materials by collapsing microscopic voids, such as pores or gaps between layers in 3D-printed parts. This fundamentally improves the material's mechanical properties without changing the component's overall shape.

The crucial insight is that HIP is not merely a surface treatment; it is a transformative process that heals internal flaws. By removing porosity, it elevates the integrity of a part, making it significantly stronger, more durable, and more reliable for demanding applications.

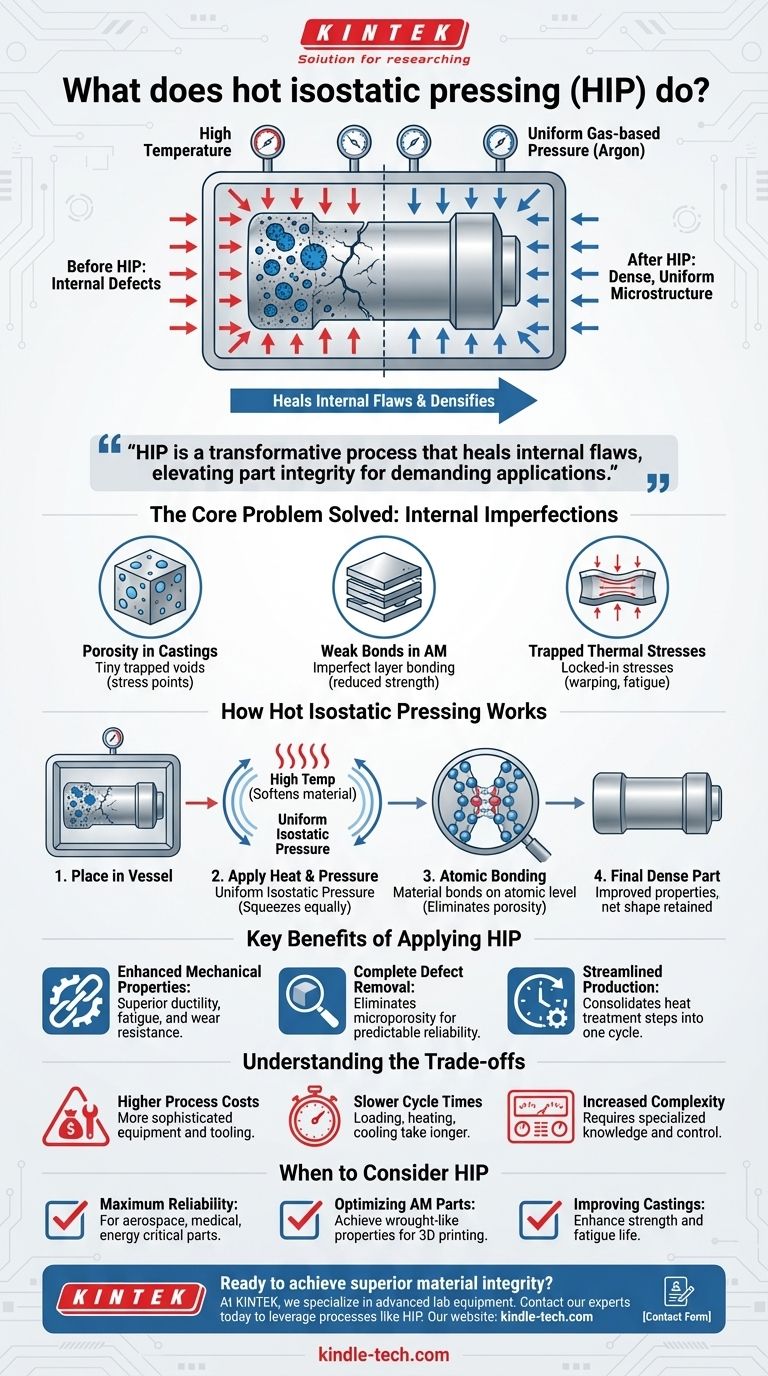

The Core Problem HIP Solves: Internal Imperfections

Many advanced manufacturing processes, like casting and additive manufacturing, can leave behind microscopic internal flaws. These defects compromise the final part's performance and reliability.

The Issue of Porosity

Porosity refers to tiny voids or pores trapped within a material during its formation. In castings or sintered parts, these pores act as stress concentration points, creating weak spots where cracks can initiate and lead to premature failure.

Weak Bonds in Additive Manufacturing

For 3D-printed metal parts, the layer-by-layer construction can result in imperfect bonding between layers. This creates microscopic gaps that reduce the component's overall strength and ductility, making it less resilient than a part made from a solid block of the same metal.

Trapped Thermal Stresses

The heating and cooling cycles inherent in casting, sintering, and 3D printing can also introduce internal thermal stresses. These locked-in stresses can cause warping or reduce the part's fatigue life over time.

How Hot Isostatic Pressing Works

HIP directly targets these internal flaws by subjecting a part to extreme conditions in a controlled environment. The process creates a uniform, dense microstructure.

Combining Heat and Pressure

The component is placed inside a high-pressure vessel that is heated to a high temperature, often just below the material's melting point. This heat makes the material soft and malleable enough for its internal structure to be reformed.

Applying Uniform (Isostatic) Pressure

An inert gas, like argon, is then pumped into the vessel, creating immense and perfectly uniform pressure from all directions. This "isostatic" pressure is key, as it squeezes the part equally on all sides, collapsing the internal pores and voids without distorting the part's net shape.

Healing Defects on a Microscopic Level

The combination of heat and pressure forces the material to bond with itself on an atomic level. This eliminates porosity, fuses layers in 3D-printed parts, and creates a dense, uniform microstructure that dramatically improves performance.

The Key Benefits of Applying HIP

By healing internal defects, HIP provides a significant upgrade to a material's properties and can even streamline the entire production workflow.

Enhanced Mechanical Properties

Parts that undergo HIP exhibit superior ductility, fatigue resistance, and wear resistance. By removing the weak points where failures begin, the process significantly increases the component's ability to withstand stress and harsh operating environments.

Complete Defect and Porosity Removal

The primary benefit is the elimination of internal microporosity in castings and sintered components. This results in a fully dense part with predictable and reliable material properties.

Streamlined Production Steps

HIP can also be used to consolidate manufacturing steps. It can combine heat treatment, quenching, and aging processes into a single cycle, reducing overall production time and complexity.

Understanding the Trade-offs

While highly effective, HIP is a specialized process with specific considerations that make it unsuitable for every application.

Higher Process Costs

Compared to simpler methods like uniaxial pressing, HIP involves more sophisticated equipment, leading to higher tooling and operational costs.

Slower Cycle Times

The process of loading, heating, pressurizing, and cooling the vessel is inherently slower than many conventional pressing methods. This can result in lower throughput and longer lead times.

Increased Process Complexity

Operating HIP equipment requires specialized knowledge and precise control over temperature and pressure parameters, adding a layer of technical complexity to the manufacturing workflow.

When to Consider Hot Isostatic Pressing

The decision to use HIP depends entirely on the performance requirements of the final component.

- If your primary focus is maximum reliability for critical components: HIP is essential for applications in aerospace, medical, or energy where part failure is not an option.

- If your primary focus is optimizing additively manufactured parts: HIP is the key to achieving mechanical properties comparable to wrought materials, unlocking the full potential of 3D printing.

- If your primary focus is improving the performance of metal castings: Use HIP to eliminate internal porosity, thereby enhancing the strength and fatigue life of cast parts.

Ultimately, hot isostatic pressing is the definitive method for achieving the highest possible material integrity from the inside out.

Summary Table:

| Key Aspect | What HIP Does |

|---|---|

| Core Process | Applies high heat and uniform gas pressure to collapse internal voids. |

| Primary Benefit | Eliminates porosity and heals internal defects, creating a dense, uniform microstructure. |

| Key Applications | Critical components in aerospace, medical implants, and improving 3D-printed (additive) and cast metal parts. |

| Main Trade-off | Higher cost and slower cycle time compared to simpler pressing methods. |

Ready to achieve superior material integrity for your critical components?

At KINTEK, we specialize in advanced lab equipment, including solutions for materials testing and processing. If your work involves developing or manufacturing high-performance metals or ceramics, our expertise can help you understand and leverage processes like Hot Isostatic Pressing to ensure maximum reliability and performance.

Contact our experts today to discuss how we can support your laboratory's mission for excellence.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What products are made from cold isostatic pressing? Achieve Uniform Density in Complex Parts

- Why is a Cold Isostatic Press (CIP) Required for NaSICON? Achieve Maximum Green Density and Ionic Conductivity

- How do industrial HIP furnaces facilitate diffusion bonding? Achieve Perfect Joints for Dissimilar Metals

- What types of materials are used for canisters in the HIP process? Optimized Choices for Material Densification

- How big is the isostatic pressing market? A Deep Dive into the $1.2B+ Advanced Manufacturing Enabler

- What is the specific function of a cold isostatic press in the sintering process of LiFePO4? Maximize Battery Density

- Why is a laboratory cold press necessary for SHS? Optimize Powder Compaction for Stable Combustion

- How much does a cold isostatic press cost? A Detailed Price Breakdown Based on Your Needs