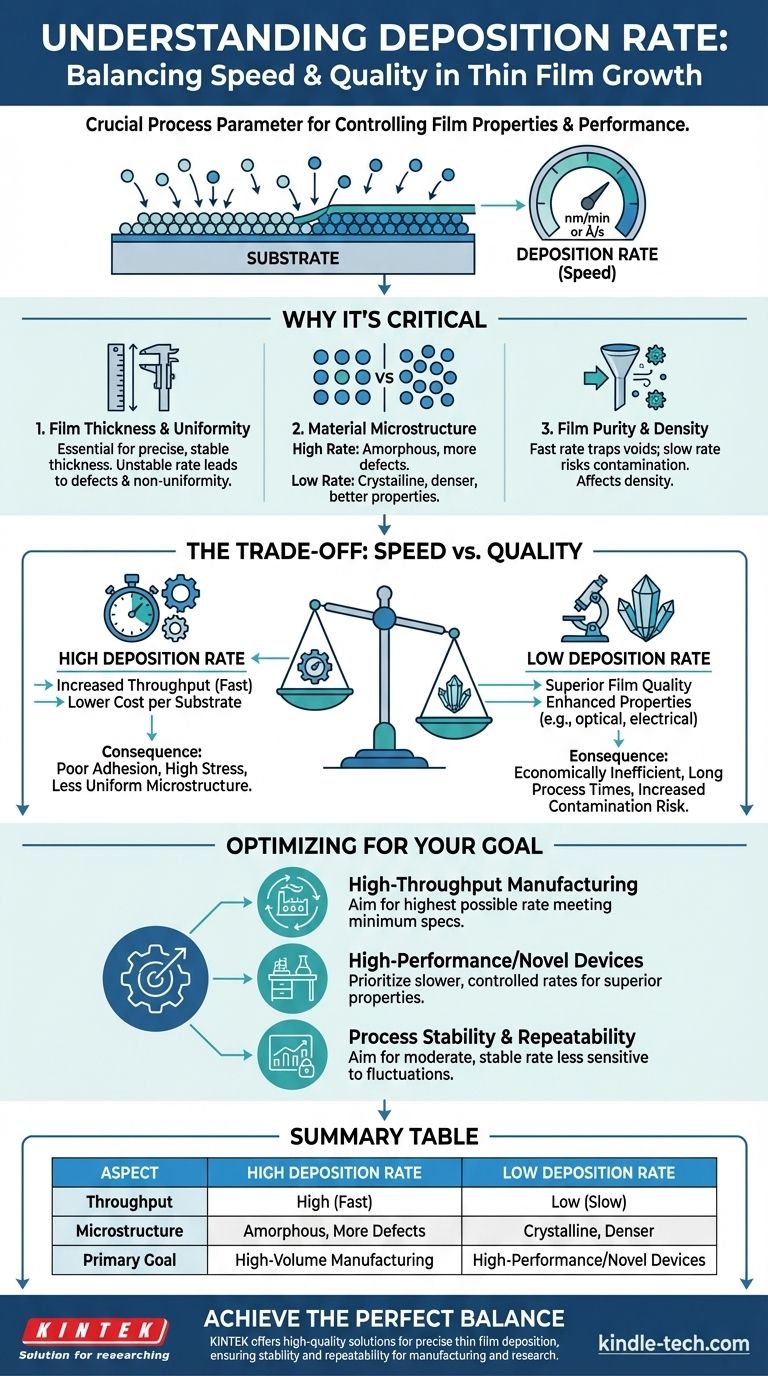

At its core, the deposition rate indicates the speed at which a thin film is grown on a surface, known as a substrate. This rate is a fundamental process parameter, typically measured in thickness per unit of time, such as nanometers per minute (nm/min) or angstroms per second (Å/s). While it simply measures speed, controlling this rate is one of the most critical factors in determining the final quality and performance of the manufactured film.

While deposition rate quantifies speed, its true significance lies in its direct control over the film's final structure, properties, and overall quality. It is not just about how fast you can make something, but how well you can make it.

Why Deposition Rate is a Critical Process Parameter

Understanding deposition rate goes beyond its definition. Its importance comes from the profound impact it has on the physical characteristics of the film you are creating.

Controlling Film Thickness and Uniformity

A stable and well-controlled deposition rate is essential for achieving a predictable final film thickness. For many applications, like semiconductor devices or optical filters, performance is directly tied to a thickness that is precise down to the single-nanometer level. An unstable rate leads to non-uniformity across the substrate, creating defects and rendering the device useless.

Influencing Material Microstructure

The speed at which atoms arrive at the substrate surface dictates how they arrange themselves.

A high deposition rate gives atoms very little time to move around and find their ideal, low-energy positions in a crystal lattice. This often results in a more disordered, or amorphous, structure with more defects.

A low deposition rate allows atoms more time to migrate on the surface, promoting the growth of a denser, more ordered, and often crystalline film. This directly affects the material's electrical, optical, and mechanical properties.

Impact on Film Purity and Density

Deposition rate also influences the purity of the film. A faster rate can effectively "bury" contaminants before they have a chance to desorb from the surface, but it can also trap voids between atoms, leading to a less dense film.

Conversely, a very slow rate can increase the chance of incorporating unwanted gas molecules from the process chamber into the film over the long deposition time, thereby reducing its purity.

Understanding the Trade-offs

Choosing a deposition rate is never about simply picking "fast" or "slow." It involves a critical balance of competing factors.

The Speed vs. Quality Dilemma

This is the central trade-off. High deposition rates increase throughput and lower the cost per substrate, which is a primary goal in commercial manufacturing.

However, this speed often comes at the expense of film quality. Pushing the rate too high can lead to poor adhesion, high internal stress, and a less uniform microstructure, all of which compromise the film's performance and reliability.

The "Slow but Not Too Slow" Problem

While slow deposition often yields superior film quality, it is economically inefficient for mass production.

Furthermore, extremely long process times increase the system's vulnerability. Any minor instability in the vacuum, temperature, or power supply over a prolonged period has a greater chance of affecting the final film, and the risk of contamination from residual gases in the chamber rises significantly.

Optimizing Deposition Rate for Your Goal

The "correct" deposition rate is entirely dependent on your objective. The ideal rate for a research prototype is rarely the same as the ideal rate for a mass-produced product.

- If your primary focus is high-throughput manufacturing: You will likely operate at the highest possible deposition rate that still meets the minimum quality and performance specifications for your device.

- If your primary focus is creating high-performance or novel devices: You should prioritize slower, highly controlled deposition rates to achieve superior film properties like density, purity, and a specific crystalline structure.

- If your primary focus is process stability and repeatability: You should aim for a moderate, well-characterized deposition rate that is less sensitive to minor system fluctuations, ensuring consistent results run after run.

Ultimately, mastering deposition rate is about finding the precise balance between manufacturing speed and the material properties your application demands.

Summary Table:

| Aspect | High Deposition Rate | Low Deposition Rate |

|---|---|---|

| Throughput | High (Fast) | Low (Slow) |

| Microstructure | Amorphous, More Defects | Crystalline, Denser |

| Primary Goal | High-Volume Manufacturing | High-Performance/Novel Devices |

Achieve the perfect balance between deposition speed and film quality for your specific application. KINTEK specializes in providing high-quality lab equipment and consumables for precise thin film deposition processes. Whether you are focused on high-throughput manufacturing or developing high-performance devices, our solutions ensure process stability and repeatability. Contact our experts today to discuss how we can optimize your deposition process and enhance your laboratory's capabilities.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is chemical Vapour deposition method for synthesis of nanomaterials? Build High-Quality Nanomaterials with Precision

- Why is a high-precision rotating sample holder necessary for Al-Zr coatings? Ensure Uniformity and Precision

- What is a physical vapor deposition process? A Guide to High-Performance Thin Film Coatings

- What is LPCVD stand for? Unlocking High-Quality, Uniform Thin Films

- What is sputtering in thin film deposition? A Guide to High-Precision PVD Coating

- What are the common precursors used in CVD reactions? A Guide to Hydrides, Halides, and Organometallics

- Why is Chemical Vapor Deposition (CVD) equipment uniquely suited for constructing hierarchical superhydrophobic structures?

- How does the newly proposed diamond formation mechanism challenge the conventional understanding? | CVD Innovation