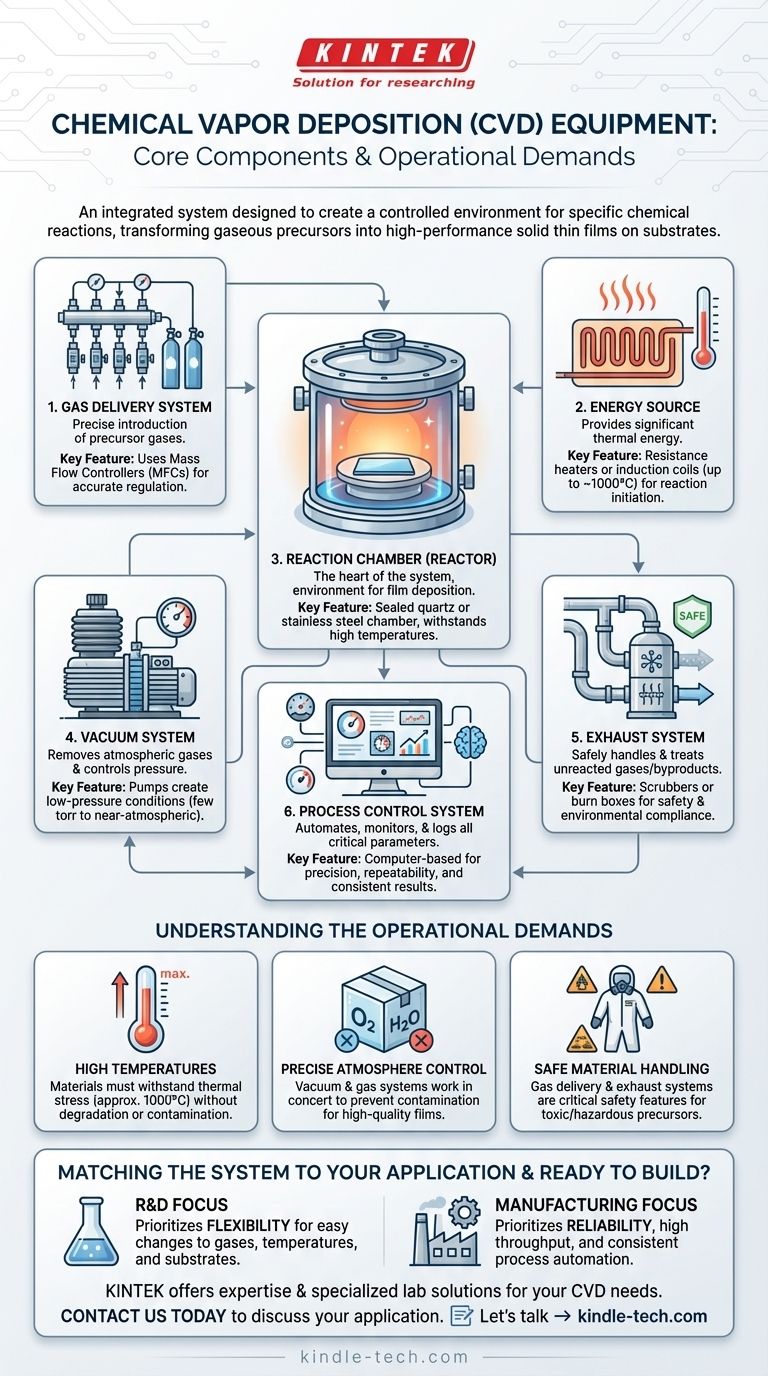

In short, a Chemical Vapor Deposition (CVD) system is an integrated set of components designed to create a highly controlled environment for a specific chemical reaction. The essential equipment includes a gas delivery system, a reaction chamber, an energy source to provide heat, a vacuum system to control pressure, and an exhaust system to safely handle byproducts. These parts are all managed by an automated process control system to ensure precision and repeatability.

A CVD apparatus is not merely a collection of hardware; it is a sophisticated system engineered to transform gaseous chemicals, known as precursors, into a high-performance solid thin film on a substrate's surface through a carefully managed high-temperature reaction.

The Core Components of a CVD System

To understand how CVD works, it is essential to understand the function of each primary component. Each part plays a critical role in managing the complex interplay of chemistry, temperature, and pressure required for high-quality film deposition.

Gas Delivery System

This system is responsible for the precise introduction of precursor gases into the reaction chamber. It uses mass flow controllers (MFCs) to meticulously regulate the flow rate of each gas, ensuring the chemical reaction has the correct recipe.

Reaction Chamber

Also known as the reactor, this is the heart of the CVD system. It is a sealed chamber, typically made of materials like quartz or stainless steel, that contains the substrate and provides the environment where the chemical reaction and film deposition occur.

Energy Source

CVD processes require significant thermal energy to initiate and sustain the chemical reactions. This energy is provided by a heating system, often using resistance heaters or induction coils, which can bring the chamber to the high temperatures required, often around 1000°C.

Vacuum System

This system, composed of one or more pumps, serves two purposes. First, it removes atmospheric gases to create a pure, controlled environment. Second, it maintains the precise low-pressure conditions (from a few torr to near-atmospheric) necessary for the specific CVD process.

Exhaust Gas Treatment

The chemical reactions in CVD produce unreacted precursor gases and other potentially hazardous byproducts. The exhaust system safely removes these from the chamber and treats them through scrubbers or burn boxes before they are released, ensuring operational safety and environmental compliance.

Process Control System

This is the brain of the operation. A computer-based control system automates, monitors, and logs all critical parameters—gas flow, temperature, pressure, and time. This automation is vital for achieving the consistent, high-quality results required in both research and industrial manufacturing.

Understanding the Operational Demands

Simply listing the equipment overlooks the significant engineering challenges involved in making them work together. The extreme conditions of a CVD process place heavy demands on every component of the system.

The Need for High Temperatures

The requirement for high temperatures dictates the material choices for the reaction chamber and internal components. These materials must be able to withstand thermal stress without degrading or contaminating the process.

Precise Atmosphere Control

The quality of the deposited film is directly tied to the purity of the reaction environment. The vacuum and gas delivery systems must work in perfect concert to prevent unwanted atmospheric contaminants like oxygen or water vapor from interfering with the chemical reaction.

Safe Material Handling

Many precursor gases used in CVD are toxic, corrosive, or flammable. This makes the gas delivery and exhaust treatment systems critical safety features, not just operational components. They must be engineered for leak-proof performance and effective neutralization of hazardous materials.

Matching the System to Your Application

The specific configuration of a CVD system depends entirely on its intended use. Understanding your end goal is the key to selecting or designing the right equipment.

- If your primary focus is research and development: Your system must prioritize flexibility, allowing for easy changes to gas mixtures, temperature profiles, and substrate types.

- If your primary focus is industrial manufacturing: Your system must be built for reliability, high throughput, and process consistency, with robust automation and loading/unloading mechanisms.

Ultimately, understanding how these core components function and interact is the foundational step toward leveraging the powerful capabilities of chemical vapor deposition.

Summary Table:

| Component | Primary Function | Key Features |

|---|---|---|

| Gas Delivery System | Precise introduction of precursor gases | Uses Mass Flow Controllers (MFCs) for accurate flow rates |

| Reaction Chamber (Reactor) | Environment for the deposition reaction | Made of quartz or stainless steel to withstand high temperatures |

| Energy Source | Provides heat to initiate/sustain reactions | Resistance heaters or induction coils (up to ~1000°C) |

| Vacuum System | Creates and maintains precise pressure conditions | Pumps to remove atmospheric gases and control pressure (from a few torr to near-atmospheric) |

| Exhaust System | Safely removes and treats byproducts | Scrubbers or burn boxes for safety and environmental compliance |

| Process Control System | Automates and monitors all parameters | Computer-based for precision, repeatability, and data logging |

Ready to build or optimize your CVD process?

The right equipment is critical for achieving high-quality, consistent thin films. Whether you are in R&D requiring flexibility or in manufacturing demanding reliability and throughput, KINTEK has the expertise and solutions to meet your laboratory's specific needs.

Contact us today to discuss how our specialized lab equipment and consumables can enhance your CVD capabilities. Let's talk about your application → #ContactForm

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is the vapor deposition of metals? Build Superior, High-Purity Metal Coatings

- Why is physical vapor deposition conducted in a high vacuum? To Ensure Purity and Performance

- How can the selective coating capability of the CVD process be enhanced? Precision Laser-Enhanced Deposition Guide

- What is the construction and working of chemical vapor deposition? A Guide to High-Purity Thin Film Fabrication

- What are the advantages of CVD? Achieve Superior, Conformal Coatings for Complex Parts

- How long does it take to make a CVD diamond? A Detailed Look at the Growth Timeline

- What is low pressure chemical vapor deposition? Achieve Superior Film Uniformity for Complex Structures

- What is the temperature range for chemical vapor deposition? From 100°C to 1200°C for Perfect Thin Films