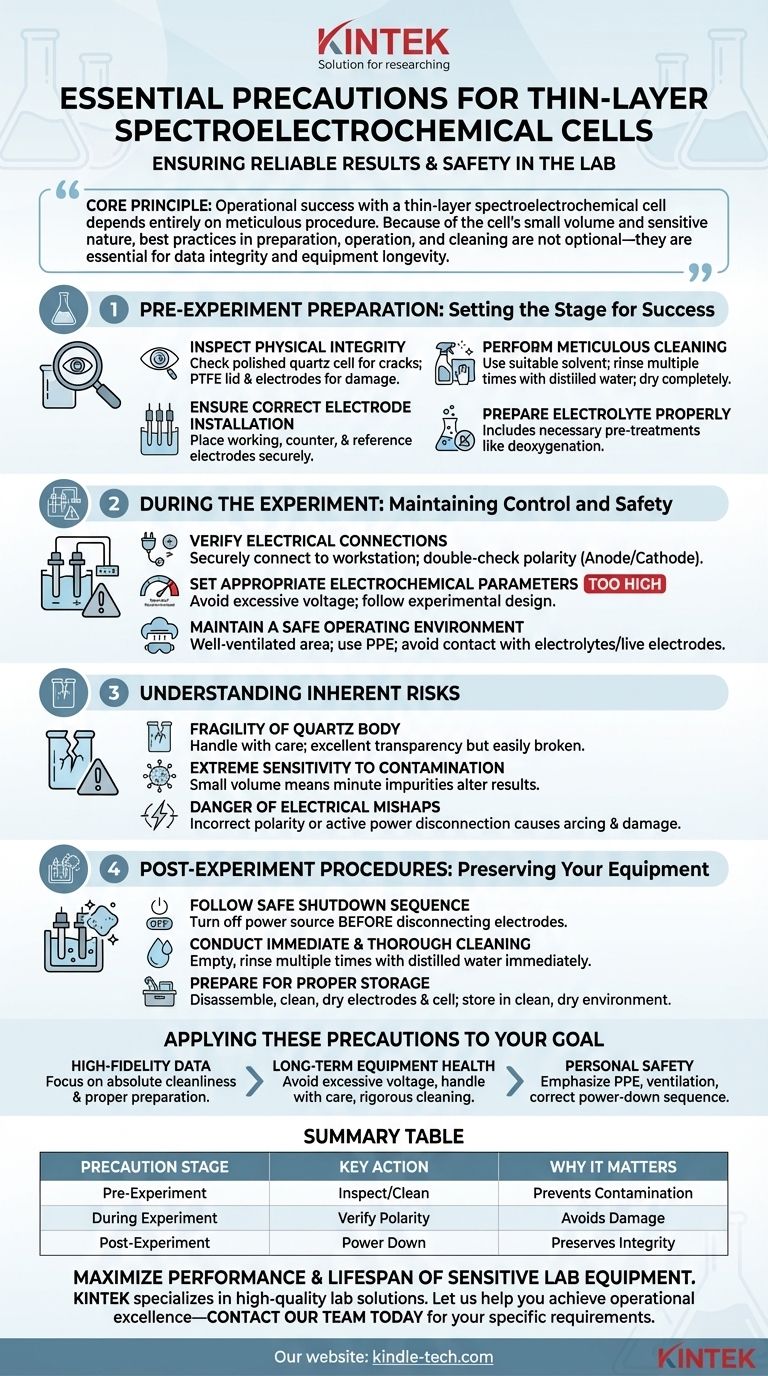

To ensure reliable results and safety, the primary precautions when using a thin-layer spectroelectrochemical cell are to verify the correct electrical polarity, meticulously prevent contaminants like dust from entering the cell, avoid applying excessive voltage that could damage the components, and use appropriate personal protective equipment when handling corrosive electrolytes.

The core principle is that operational success with a thin-layer spectroelectrochemical cell depends entirely on meticulous procedure. Because of the cell's small volume and sensitive nature, best practices in preparation, operation, and cleaning are not optional—they are essential for data integrity and equipment longevity.

Pre-Experiment Preparation: Setting the Stage for Success

Before any experiment begins, a rigorous preparation routine is the first line of defense against erroneous data and equipment damage.

Inspect for Physical Integrity

First, carefully inspect all components. Check the integrally polished quartz cell body for any cracks or chips, as it is fragile. Ensure the PTFE lid and all electrodes are present and free from damage.

Perform Meticulous Cleaning

Thoroughly clean the cell with a suitable solvent to remove any residual impurities from previous use. Rinse it several times with distilled water and allow it to dry completely before assembly.

Ensure Correct Electrode Installation

Install the working, counter, and reference electrodes into their designated positions. Proper placement and secure contact are critical for stable and accurate electrochemical measurements.

Prepare the Electrolyte Properly

Prepare the electrolyte as required by your experiment. This may include necessary pre-treatments, such as deoxygenation, to remove dissolved oxygen that can interfere with many electrochemical reactions.

During the Experiment: Maintaining Control and Safety

Executing the experiment requires constant attention to both the equipment settings and the surrounding environment.

Verify Electrical Connections

Securely connect the cell's electrodes to your electrochemical workstation. Double-check that the anode and cathode connections have the correct polarity to avoid experimental failure or damage to the electrodes.

Set Appropriate Electrochemical Parameters

Set the electrochemical parameters, such as potential and current, according to your experimental design. Applying excessively high voltage is a common mistake that can lead to electrolyte decomposition or permanent damage to the electrode surfaces.

Maintain a Safe Operating Environment

Always operate in a well-ventilated area, as the electrolysis process may produce harmful gases. Avoid any direct physical contact with the electrolyte and live electrodes to prevent electric shock, chemical burns, or poisoning.

Understanding the Inherent Risks

The design of a thin-layer cell presents unique challenges that you must manage proactively.

The Fragility of the Quartz Body

The cell body is typically made from polished quartz, which offers excellent optical transparency but is also very fragile. It must be handled with care at all times to prevent breakage.

Extreme Sensitivity to Contamination

The very small volume of a thin-layer cell means that even minute amounts of dust or other impurities can significantly alter the concentration of your analyte and affect the results. Meticulous cleaning is non-negotiable.

The Danger of Electrical Mishaps

Incorrect polarity can ruin an experiment. Furthermore, connecting or disconnecting the cell while the power source is active can cause electrical arcing, which poses a safety risk and can damage the sensitive electronics of the workstation.

Post-Experiment Procedures: Preserving Your Equipment

Proper shutdown and cleaning procedures are essential for ensuring the cell is ready for future use and will last a long time.

Follow a Safe Shutdown Sequence

Always turn off the power source on your electrochemical workstation before disconnecting the cell's electrodes. This simple step prevents electrical hazards and protects your equipment.

Conduct Immediate and Thorough Cleaning

As soon as the experiment is over, empty the electrolyte from the cell. Immediately rinse the cell multiple times with distilled water to remove all residual electrolyte and reaction byproducts before they can dry or adsorb onto the surfaces.

Prepare for Proper Storage

Carefully disassemble the electrodes, clean them thoroughly according to their specific requirements, and allow them to dry. Ensure the quartz cell and all other components are completely dry before storing them in a clean, dry environment protected from dust and moisture.

Applying These Precautions to Your Goal

Your specific experimental focus will determine which precautions demand the most attention.

- If your primary focus is high-fidelity, repeatable data: Your priority must be absolute cleanliness to prevent contamination and proper electrolyte preparation like deoxygenation.

- If your primary focus is long-term equipment health: Pay closest attention to avoiding excessive voltage, handling the fragile quartz body with care, and following rigorous post-experiment cleaning and drying procedures.

- If your primary focus is personal safety: Emphasize using protective gear with corrosive materials, ensuring good ventilation, and always following the correct power-down sequence to avoid electrical hazards.

Adopting these disciplined practices transforms the spectroelectrochemical cell from a delicate instrument into a powerful and reliable tool for discovery.

Summary Table:

| Precaution Stage | Key Action | Why It Matters |

|---|---|---|

| Pre-Experiment | Inspect cell, clean meticulously, deoxygenate electrolyte. | Prevents contamination and ensures baseline accuracy. |

| During Experiment | Verify electrical polarity, set safe voltage limits, use PPE. | Avoids equipment damage and ensures operator safety. |

| Post-Experiment | Power down before disconnecting, clean immediately, store dry. | Preserves cell integrity and longevity for future use. |

Maximize the performance and lifespan of your sensitive lab equipment. The precise procedures outlined above are essential for any laboratory using spectroelectrochemical cells. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your research needs. Our experts understand the critical importance of meticulous technique for accurate results. Let us help you achieve operational excellence—contact our team today to discuss your specific laboratory requirements and discover how KINTEK's solutions can support your success.

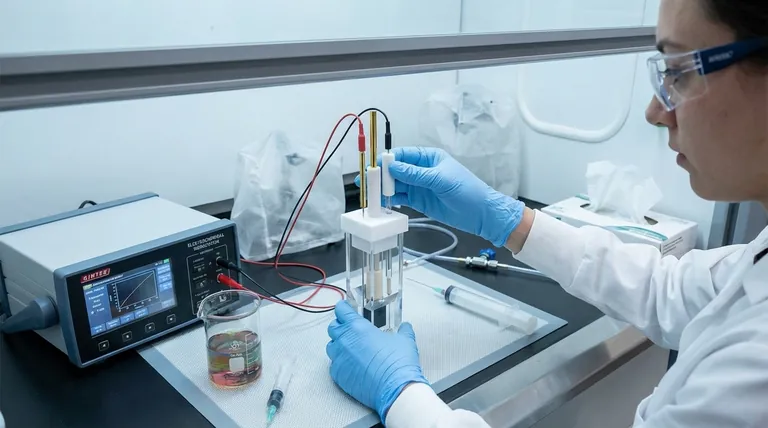

Visual Guide

Related Products

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Electrolytic Electrochemical Cell with Five-Port

People Also Ask

- What types and sizes of electrodes are typically configured with a thin-layer spectroelectrochemical cell? Standard Setup for Accurate Analysis

- What are the physical dimensions of the thin-layer spectroelectrochemical cell body and its slit? Key Specs for Your Lab

- What preparation steps are required before initiating an experiment with the thin-layer spectroelectrochemical cell?

- What is the correct post-experiment procedure for a thin-layer spectroelectrochemical cell? A Step-by-Step Guide for Lab Safety and Accuracy

- What are the key maintenance and handling procedures for a thin-layer spectroelectrochemical cell? Protect Your Sensitive Lab Equipment