Brazing is a critical joining process used across a diverse and demanding range of high-tech industries. Its applications are found in aerospace, defense, automotive, medical, power generation, and semiconductor manufacturing. The process is used to create everything from complex automotive and hydraulic components to highly precise assemblies for scientific and medical instruments.

The widespread use of brazing is not based on a single benefit, but on its unique capability to create strong, clean, and leak-proof joints without melting or distorting the parent materials. This makes it indispensable for manufacturing high-value, precision components where other joining methods would fail.

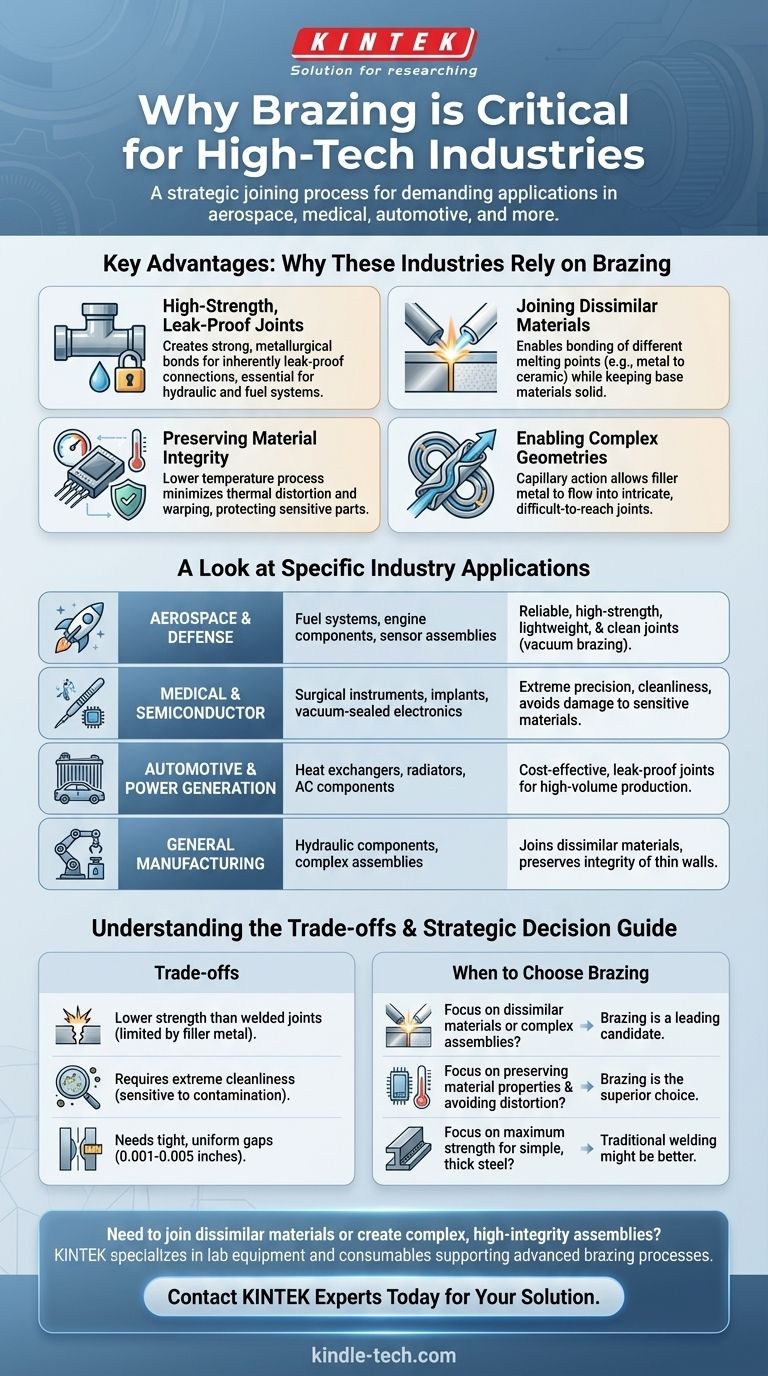

Why These Industries Rely on Brazing

The choice to use brazing is a strategic engineering decision. It is selected when the properties of the final assembly are more important than the raw speed or cost of the joining process itself.

Achieving High-Strength, Leak-Proof Joints

Brazing creates a strong, metallurgical bond between components. The filler metal melts and is drawn into the tight-fitting joint by capillary action, forming a solid, continuous connection upon cooling.

This process results in joints that are exceptionally strong and inherently leak-proof, a critical requirement for hydraulic fittings in automotive systems and fuel lines in aerospace.

Joining Dissimilar Materials

One of brazing's most significant advantages is its ability to join materials with different melting points, such as copper to steel or ceramic to metal.

Since only the filler metal melts, the base materials remain solid. This capability is essential for creating complex electromechanical assemblies found in defense and medical devices.

Preserving Material Integrity

Brazing is performed at temperatures significantly lower than welding. The heat is applied broadly and is below the melting point of the components, which drastically reduces the risk of thermal distortion, warping, or changes to the material's temper.

This makes it the ideal choice for joining thin-walled tubes, delicate electronic components in the semiconductor industry, or precision-machined parts that must maintain tight tolerances.

Enabling Complex Geometries

The capillary action of brazing allows the filler metal to flow into intricate, non-linear, and difficult-to-reach joints.

Brazing is perfectly suited for assemblies with multiple joints, internal channels, or connections with restricted access, which are common challenges in aerospace and advanced machinery.

A Look at Specific Industry Applications

Understanding where and why brazing is used provides a clearer picture of its capabilities.

Aerospace and Defense

In this sector, reliability is paramount. Brazing is used for its ability to produce high-strength, lightweight joints in fuel systems, engine components, and sensor assemblies. Vacuum brazing, in particular, ensures exceptionally clean, strong joints free from contaminants.

Automotive and Power Generation

Brazing is a cost-effective solution for high-volume production. It is used extensively to manufacture heat exchangers, radiators, and air conditioning components where thousands of joints must be made reliably and be leak-proof.

Medical and Semiconductor

These industries demand extreme cleanliness and precision. Brazing is used to assemble surgical instruments, medical implants, and vacuum-sealed electronic components. The low-temperature, clean nature of the process prevents contamination and damage to sensitive materials.

Understanding the Trade-offs

No process is perfect for every situation. Being a trusted advisor means acknowledging the limitations of brazing.

Lower Strength Than Welded Joints

While a brazed joint is strong, it is generally not as strong as a properly welded joint between the same two parent metals. The strength is limited by the shear strength of the filler metal itself.

Requirement for Extreme Cleanliness

Brazing is highly sensitive to surface contamination. The parts must be meticulously cleaned of all oils, oxides, and debris before heating. Failure to do so will prevent the filler metal from wetting the surfaces and flowing into the joint, resulting in a failed bond.

Need for Tight and Uniform Gaps

Capillary action, the physical principle behind brazing, only works when the gap between the two components is very small and consistent (typically 0.001 to 0.005 inches). This requires precise machining and fit-up, which can add to manufacturing costs.

How to Determine if Brazing is Right for Your Application

Use these guidelines to make a strategic decision for your project.

- If your primary focus is joining dissimilar materials or a complex assembly: Brazing is a leading candidate due to its flexibility and ability to join different material families without melting them.

- If your primary focus is preserving material properties and avoiding distortion: Brazing is likely the superior choice, especially for thin materials or components that have already been heat-treated or precision-machined.

- If your primary focus is the absolute maximum joint strength on simple, thick steel components: A traditional welding process might be a more direct and robust solution.

Ultimately, selecting brazing is a strategic engineering decision that prioritizes design flexibility, material integrity, and joint precision.

Summary Table:

| Industry | Key Applications | Why Brazing is Used |

|---|---|---|

| Aerospace & Defense | Fuel systems, engine components, sensors | High-strength, lightweight, clean joints (vacuum brazing) |

| Medical & Semiconductor | Surgical instruments, implants, electronics | Precision, cleanliness, avoids damaging sensitive materials |

| Automotive & Power Generation | Heat exchangers, radiators, AC components | Cost-effective, leak-proof joints for high-volume production |

| General Manufacturing | Hydraulic components, complex assemblies | Joins dissimilar materials, preserves integrity of thin walls |

Need to join dissimilar materials or create complex, high-integrity assemblies? The strategic advantages of brazing—preserving material properties, enabling complex geometries, and creating leak-proof joints—are essential for high-value manufacturing. KINTEK specializes in the lab equipment and consumables that support advanced brazing processes, serving the precise needs of laboratories and R&D departments. Let our experts help you determine if brazing is the right solution for your project. Contact us today to discuss your specific application requirements.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- Which element made stainless steel difficult to brazed? It's Chromium's Oxide Layer

- What is a braze repair process? A Low-Heat Solution for Strong, Seamless Metal Joining

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints

- What are the factors that affect the strength of a brazed joint? Master the 4 Keys to a Perfect Bond