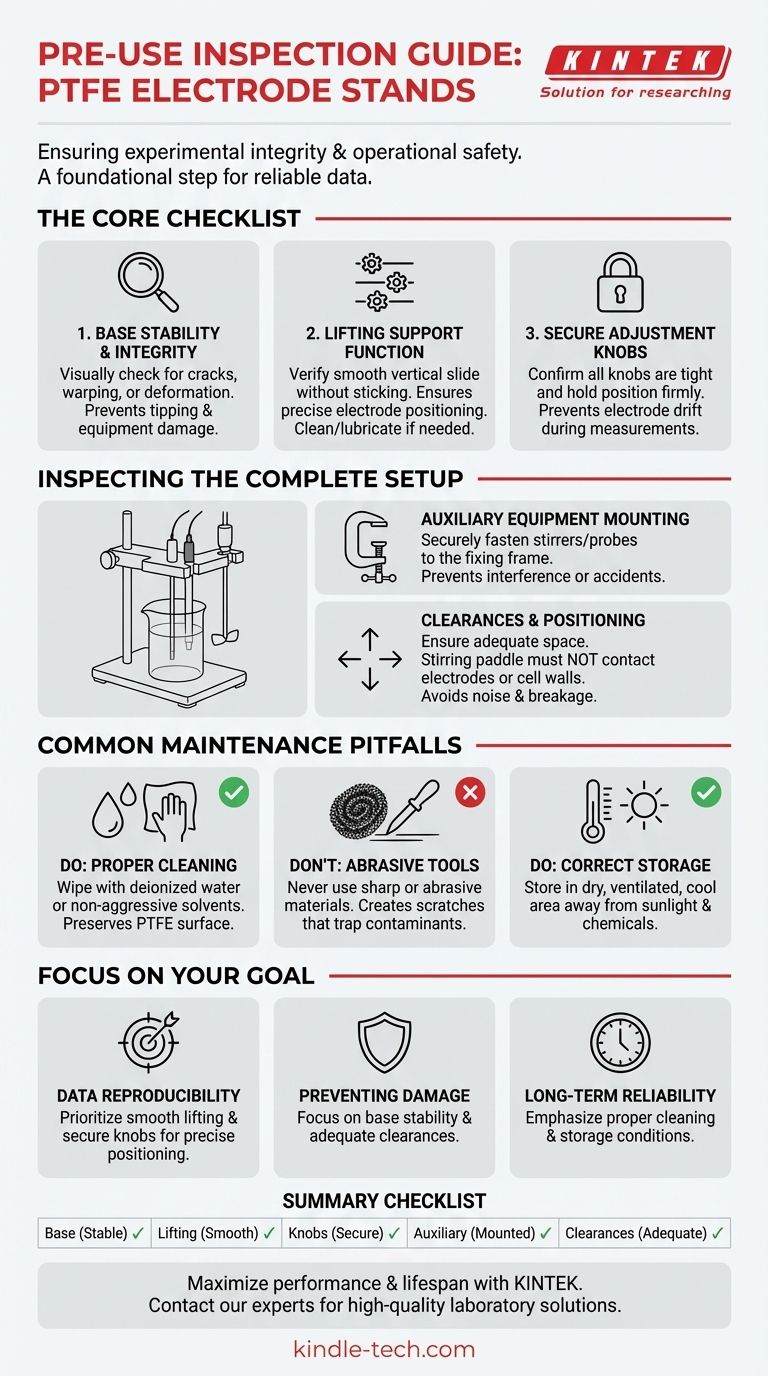

Before any use, a thorough inspection of your PTFE electrode stand is critical for both experimental integrity and operational safety. The primary checks involve confirming the base is stable and free of cracks, verifying the lifting support slides smoothly, and ensuring all adjustment knobs are secure and not loose.

A pre-use inspection is not a mere formality; it is a foundational step to guarantee the stability and reproducibility of your electrochemical setup. This simple routine prevents costly experimental errors and protects valuable equipment from damage before it can occur.

The Core Pre-Use Inspection Checklist

A systematic check ensures that every critical component of the stand is ready for the demands of a precise experiment.

Base Stability and Integrity

The foundation of your entire setup is the stand's base. Visually inspect it for any cracks, warping, or other signs of deformation.

An unstable or damaged base can cause the entire assembly to tip over, leading to broken equipment and ruined experiments.

Mechanical Function of the Lifting Support

The vertical slide or lifting mechanism is essential for precise electrode positioning. Verify that the support slides smoothly up and down its track without sticking or stuttering.

If the mechanism is stuck, it may be contaminated with impurities. Clean it thoroughly and, if necessary, apply a small amount of appropriate lubricant to restore smooth operation.

Security of Adjustment Knobs

All adjustment knobs, which lock the height and position of the electrodes, must be secure. Attempt to move the supports by hand after tightening the knobs.

Any looseness can cause the electrodes to drift out of position during a measurement, invalidating your data.

Inspecting the Complete Experimental Setup

The stand does not operate in isolation. Its interaction with other equipment is a common point of failure that a pre-use check can prevent.

Auxiliary Equipment Mounting

If you are using stirrers, probes, or temperature sensors, ensure they are securely fastened to the stand's auxiliary fixing frame.

A poorly mounted device can slip and interfere with the experiment or fall and cause damage.

Clearances and Positioning

Critically, confirm that all components have adequate clearance. Ensure that a stirring paddle does not make contact with the electrodes or the wall of the electrolytic cell.

Contact can introduce electrical noise into your measurement, physically damage expensive electrodes, or break fragile glassware.

Common Pitfalls in Stand Maintenance

Proper care is essential for the long-term reliability of a PTFE stand. Avoiding common mistakes during cleaning and storage preserves its integrity.

The Risk of Improper Cleaning

The recommended cleaning method is to wipe all surfaces with deionized water or a suitable, non-aggressive solvent.

Never use sharp or abrasive tools like steel wool for cleaning. These materials will create scratches on the PTFE surface that can trap chemical contaminants and compromise future experiments.

The Importance of Correct Storage

Store the electrode stand in a dry, ventilated, and cool environment, away from direct sunlight or high-temperature sources.

It is also crucial to prevent the stand from coming into prolonged contact with other chemicals, which could cause a reaction and degrade the PTFE material.

Making the Right Choice for Your Goal

This inspection routine ensures your equipment is always ready for the task at hand.

- If your primary focus is data reproducibility: Pay closest attention to the lifting support's smooth travel and the absolute security of the adjustment knobs to guarantee precise electrode positioning.

- If your primary focus is preventing equipment damage: Prioritize the base's stability and the clearance between auxiliary equipment (like stirrers) and the electrodes.

- If your primary focus is long-term reliability: Emphasize proper cleaning techniques and correct storage conditions to maximize the stand's operational lifespan.

This disciplined, pre-use check is a small investment of time that protects the significant investment in your research.

Summary Table:

| Inspection Area | Key Checkpoints | Importance |

|---|---|---|

| Base & Stability | Check for cracks, warping, or deformation. | Prevents tipping and protects equipment. |

| Lifting Support | Verify smooth vertical slide without sticking. | Ensures precise and reproducible electrode positioning. |

| Adjustment Knobs | Confirm knobs are secure and hold position firmly. | Prevents electrode drift during measurements. |

| Auxiliary Equipment | Ensure stirrers/probes are mounted securely. | Avoids interference, damage, or accidents. |

| Clearances | Check for adequate space between components (e.g., stirrer and electrodes). | Prevents contact, electrical noise, and breakage. |

Maximize the performance and lifespan of your laboratory equipment.

A rigorous pre-use inspection is the first step to reliable data. For all your lab equipment needs—from durable PTFE electrode stands to precision instruments and consumables—trust KINTEK. We specialize in providing high-quality solutions that meet the demanding requirements of modern laboratories.

Contact our experts today to discuss how KINTEK can support your research goals with reliable equipment and expert guidance.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Custom PTFE Teflon Parts Manufacturer for Three-Necked Round Bottom Flask

- Custom PTFE Teflon Parts Manufacturer for Sampling Solution Sample and Dry Powder Spoons

People Also Ask

- What is the proper post-treatment procedure for a platinum sheet electrode? Ensure Long-Term Accuracy & Protect Your Investment

- What are the performance characteristics of platinum sheet electrodes? Unlock Superior Electrochemical Performance

- How should a platinum sheet electrode be operated during an experiment? Ensure Accurate and Reproducible Results

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance

- What precautions should be taken when using a platinum sheet electrode? Ensure Accurate & Reproducible Electrochemical Data