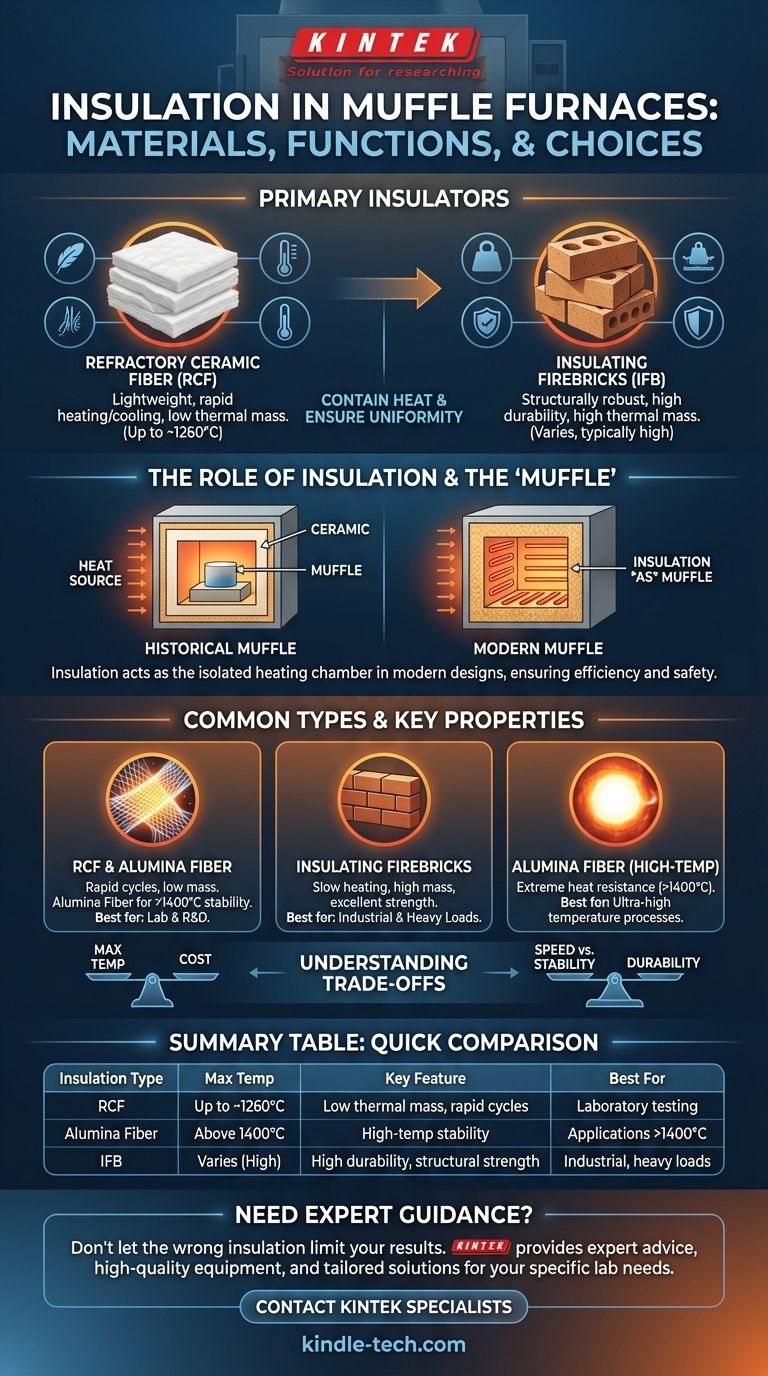

The primary insulators used in modern muffle furnaces are high-performance refractory ceramic fibers and insulating firebricks. These materials are chosen for their ability to withstand extreme temperatures while having very low thermal conductivity. In many contemporary designs, this insulation layer also serves as the muffle itself, creating the isolated heating chamber.

The choice of insulation is not arbitrary; it's a critical engineering decision that balances the furnace's maximum temperature, heating speed, durability, and cost. While ceramic fibers offer rapid heating and superior insulation, firebricks provide structural robustness.

Why Insulation is the Core of a Muffle Furnace

A muffle furnace is designed to create a highly uniform and isolated high-temperature environment. The insulation is the most critical component in achieving this goal.

The Role of the "Muffle"

Historically, a muffle was a separate inner chamber made of a high-temperature ceramic. It protected the sample from the direct flames and combustion byproducts of the heat source.

Modern electric furnaces often have no separate muffle. Instead, the heating elements are embedded within or placed just behind a rigid, high-purity insulation shell, which forms the heating chamber. This insulation acts as the muffle.

The Function of the Insulator

The insulation's primary job is to contain the heat generated by the electric heating elements. Effective insulation ensures temperature stability, energy efficiency, and keeps the external shell of the furnace cool and safe to touch.

Common Types of Muffle Furnace Insulation

The material used depends directly on the furnace's intended operating temperature and application.

Refractory Ceramic Fiber (RCF)

Refractory Ceramic Fiber (also called alumina-silica fiber) is the most common insulator in modern laboratory muffle furnaces. It is lightweight, has extremely low thermal conductivity, and very low thermal mass.

This low thermal mass allows the furnace to heat up and cool down very quickly, which is ideal for many research and testing applications. RCF is typically used in the form of rigid boards or vacuum-formed shapes to create the chamber.

Alumina Fiber

For applications requiring temperatures above 1400°C (2550°F), high-purity alumina fibers are used. These are a type of polycrystalline ceramic fiber that maintains stability at very high temperatures where standard RCF would begin to degrade.

Insulating Firebricks (IFB)

Insulating Firebricks are lightweight, porous bricks made from refractory clays. They have a much higher density and thermal mass compared to ceramic fibers.

While they take longer to heat up, they are mechanically robust and have excellent structural strength. They are often used to construct the primary chamber in larger, more rugged industrial furnaces that see heavy use and potential mechanical stress.

Understanding the Trade-offs and Key Properties

Selecting the right insulation involves balancing several competing factors.

Maximum Service Temperature vs. Cost

This is the most important consideration. The maximum temperature a material can withstand dictates its use. High-purity alumina fibers for 1700°C+ applications are significantly more expensive than standard RCF rated for 1260°C.

Thermal Mass: Speed vs. Stability

Ceramic fibers have low thermal mass, enabling rapid heat-up and cool-down. This is a major advantage for processes requiring quick cycles.

Insulating firebricks have high thermal mass, meaning they heat and cool slowly. However, this high mass can also contribute to better temperature uniformity and stability once the furnace is at its setpoint.

Durability and Repair

Firebricks are hard and resistant to abrasion but can crack under severe thermal shock. Ceramic fiber boards are more fragile and can be easily damaged by physical contact, but they handle thermal cycling very well.

Making the Right Choice for Your Goal

The optimal insulation is directly tied to the furnace's primary function.

- If your primary focus is rapid heating for laboratory testing: Your furnace will almost certainly use a low-mass insulator like Refractory Ceramic Fiber (RCF) or high-purity Alumina Fiber.

- If your primary focus is industrial production with heavy loads: Your furnace likely uses Insulating Firebricks for their structural durability, potentially with a fiber lining for added efficiency.

- If your primary focus is cost-effective general use up to 1200°C: A furnace built with standard RCF provides the best balance of performance and cost.

Ultimately, the insulating material defines the performance, capabilities, and limits of the entire furnace.

Summary Table:

| Insulation Type | Max Temperature | Key Feature | Best For |

|---|---|---|---|

| Refractory Ceramic Fiber (RCF) | Up to ~1260°C (2300°F) | Low thermal mass, rapid heating/cooling | Laboratory testing, rapid cycles |

| Alumina Fiber | Above 1400°C (2550°F) | High-temperature stability | Applications >1400°C |

| Insulating Firebricks (IFB) | Varies, typically high | High durability, structural strength | Industrial production, heavy loads |

Need Help Selecting the Right Muffle Furnace?

Choosing the correct insulation is critical for your furnace's performance, efficiency, and longevity. The experts at KINTEK are here to help you navigate these technical decisions.

We provide:

- Expert Guidance: We'll help you select the ideal furnace based on your specific temperature requirements, application (lab testing vs. industrial production), and desired heating speed.

- High-Quality Equipment: KINTEK supplies reliable muffle furnaces built with the appropriate high-performance insulation to ensure precise temperature control and energy efficiency.

- Tailored Solutions: Whether you need the rapid heating of ceramic fiber for R&D or the rugged durability of firebricks for production, we have a solution for your laboratory needs.

Don't let the wrong insulation limit your results. Contact our technical specialists today for a personalized consultation and ensure your furnace is optimized for your success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

People Also Ask

- What is ash content determination? Ensure Food Quality, Safety, and Compliance

- What is the purpose of the 400 °C annealing for ceramic green bodies? Ensure Structural Integrity & Prevent Cracking

- What is the purpose of high-temperature muffle furnaces and ceramic crucibles? Master NREL Ash Analysis

- What is the function of a high-temperature muffle furnace for duplex stainless steel? Optimize Alloy Performance

- What is the primary function of a sintering furnace in the powder metallurgy process? Mastering Gradient Materials

- Why is a high-temperature box resistance furnace necessary for mixed rare earth niobate synthesis? | KINTEK

- How do high-precision box furnaces facilitate g-C3N4 synthesis? Optimize Your Thermal Polycondensation Process

- Why do we use muffle furnace? For Unmatched Purity and Precision in High-Temp Processing