In essence, a controlled atmosphere temperature treatment system is an advanced industrial furnace or oven that precisely manages two critical variables: the temperature and the chemical composition of the gas surrounding a product. Its primary purpose is to heat materials while preventing unwanted reactions like oxidation (rust) or, conversely, to intentionally induce specific chemical changes on the material's surface.

The crucial insight is that this technology moves beyond simple heating. By controlling the gaseous environment, it transforms a furnace from a blunt instrument into a precision tool for manipulating material properties, ensuring higher quality and enabling advanced manufacturing processes.

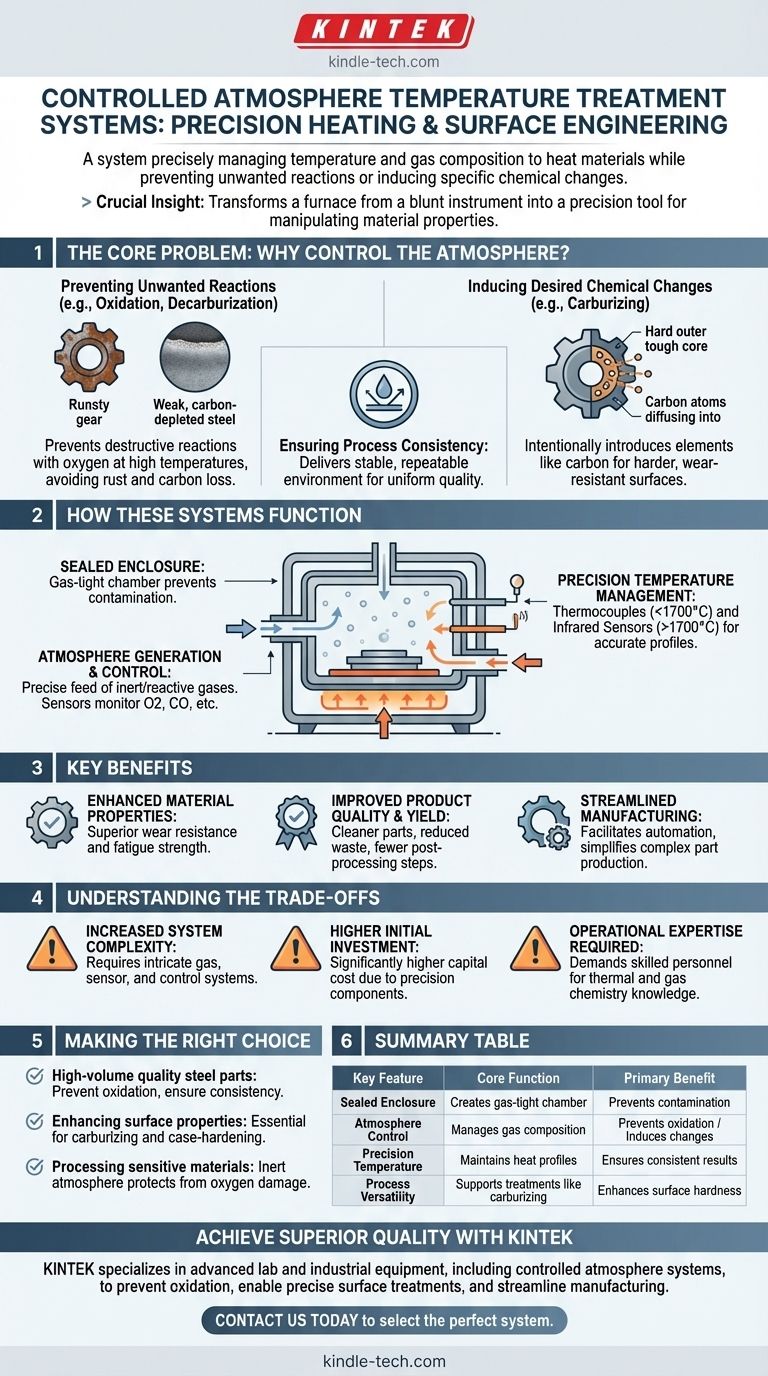

The Core Problem: Why Control the Atmosphere?

Heating materials in normal air, which is rich in oxygen, can be destructive. At high temperatures, oxygen aggressively reacts with many materials, causing significant damage. Controlled atmosphere systems are designed to solve this fundamental problem.

Preventing Unwanted Reactions

The most common goal is to create a protective environment. By replacing oxygen-rich air with specific gases (often inert or reactive in a controlled way), these systems prevent harmful chemical changes.

Two key examples in steel treatment are oxidation (the formation of scale or rust) and decarburization, which is the loss of carbon content from the steel's surface, making it softer and weaker.

Inducing Desired Chemical Changes

Conversely, these systems can be used to intentionally introduce elements into a material's surface.

A primary example is carburizing, where a carbon-rich atmosphere is used to diffuse carbon into the surface of low-carbon steel. This creates a part with an extremely hard, wear-resistant exterior while maintaining a tougher, more ductile core.

Ensuring Process Consistency

By removing the variability of ambient air, these systems provide a stable, repeatable environment. This level of process control is critical for modern manufacturing, as it ensures that every part meets the exact same quality standards.

How These Systems Function

A controlled atmosphere system integrates several key components to achieve its goal. While designs vary, the core principles remain the same.

The Sealed Enclosure

The process takes place within a furnace or oven that is sealed to be gas-tight. This enclosure prevents the controlled atmosphere from escaping and outside air from leaking in, which would contaminate the process.

Atmosphere Generation and Control

A specific gas or mixture of gases is fed into the chamber. This can include inert gases like nitrogen and argon to prevent any reaction, or precisely mixed reactive gases to achieve a specific chemical outcome. Sophisticated sensors constantly monitor and adjust the levels of gases like O2, CO, and water vapor.

Precision Temperature Management

Accurate temperature control is paramount. These systems use advanced sensors, such as thermocouples for lower temperatures (below 1700°C) and infrared instruments for higher temperatures. This data feeds into an automated control unit that maintains the temperature profile with exceptional accuracy.

Key Benefits of Controlled Atmosphere Treatment

Adopting this technology offers significant advantages in efficiency, quality, and capability.

Enhanced Material Properties

By preventing decarburization or by performing surface treatments like carburizing, the final product exhibits superior wear resistance and fatigue strength. This leads to more durable and reliable components.

Improved Product Quality and Yield

The process dramatically reduces or eliminates issues like scaling and burning. This results in cleaner parts, higher qualification rates, and a significant reduction in wasted material and post-processing steps like cleaning or machining.

Streamlined Manufacturing

These systems facilitate the automation of heat treatment, which improves productivity and reduces labor intensity. They can also simplify the manufacturing of complex parts by allowing the use of softer, easier-to-machine metals that are then surface-hardened.

Understanding the Trade-offs

While powerful, this technology is not a universal solution. An objective assessment requires acknowledging its complexities.

Increased System Complexity

A controlled atmosphere furnace is inherently more complex than a standard air-fired oven. It requires gas generation or supply systems, intricate sensor arrays, and sophisticated control logic, all of which must work in unison.

Higher Initial Investment

The added complexity and precision components mean that the initial capital cost for a controlled atmosphere system is significantly higher than for simpler alternatives.

Operational Expertise Required

Properly operating and maintaining these systems demands a higher level of technical skill. Personnel must understand not only the thermal process but also the gas chemistry and control systems to ensure safe and effective operation.

Making the Right Choice for Your Goal

The decision to use a controlled atmosphere system depends entirely on the material requirements and production goals.

- If your primary focus is high-volume production of quality steel parts: This technology is critical for preventing oxidation and decarburization, ensuring consistent mechanical properties and reducing rework.

- If your primary focus is enhancing surface properties: A controlled atmosphere is essential for case-hardening processes like carburizing, which create parts with a uniquely hard surface and tough core.

- If your primary focus is processing sensitive or reactive materials: An inert atmosphere is the only way to protect materials (like certain electronics or exotic alloys) that would be damaged or destroyed by oxygen at high temperatures.

Ultimately, adopting a controlled atmosphere system is an investment in precision, repeatability, and the final quality of your product.

Summary Table:

| Key Feature | Core Function | Primary Benefit |

|---|---|---|

| Sealed Enclosure | Creates a gas-tight processing chamber | Prevents contamination from ambient air |

| Atmosphere Control | Manages gas composition (e.g., inert, reactive) | Prevents oxidation or induces surface changes |

| Precision Temperature | Accurately maintains specific heat profiles | Ensures consistent, repeatable results |

| Process Versatility | Supports treatments like carburizing | Enhances surface hardness and wear resistance |

Ready to achieve superior quality and consistency in your heat treatment processes?

KINTEK specializes in advanced lab and industrial equipment, including controlled atmosphere systems. Our solutions are designed to prevent oxidation, enable precise surface treatments, and streamline your manufacturing workflow.

Contact us today to discuss how our expertise in lab equipment and consumables can help you select the perfect system for your material and production goals.

Get in touch with our experts now!

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is an atmosphere control furnace essential for TiMoOx synthesis? Protect Carbon Supports & Enhance Oxides

- How is a tube atmosphere furnace utilized in Si-CNF anode preparation? Master High-Performance Carbonization

- What is the necessity of providing an inert gas environment in atmosphere furnaces? Key for Biomass Carbonization

- Why does argon displace oxygen? The Silent Danger of a Denser Gas

- Why is argon used in furnace? To Protect Materials from Oxidation at High Temperatures

- How do laboratory atmosphere furnaces facilitate the sintering of Ti2AlC foams? Achieve High-Strength Porous Ceramics

- What is the purpose of inerting? Prevent Fires, Explosions, and Product Degradation

- What does inerting a space mean? A Guide to Eliminating Fire and Explosion Risks