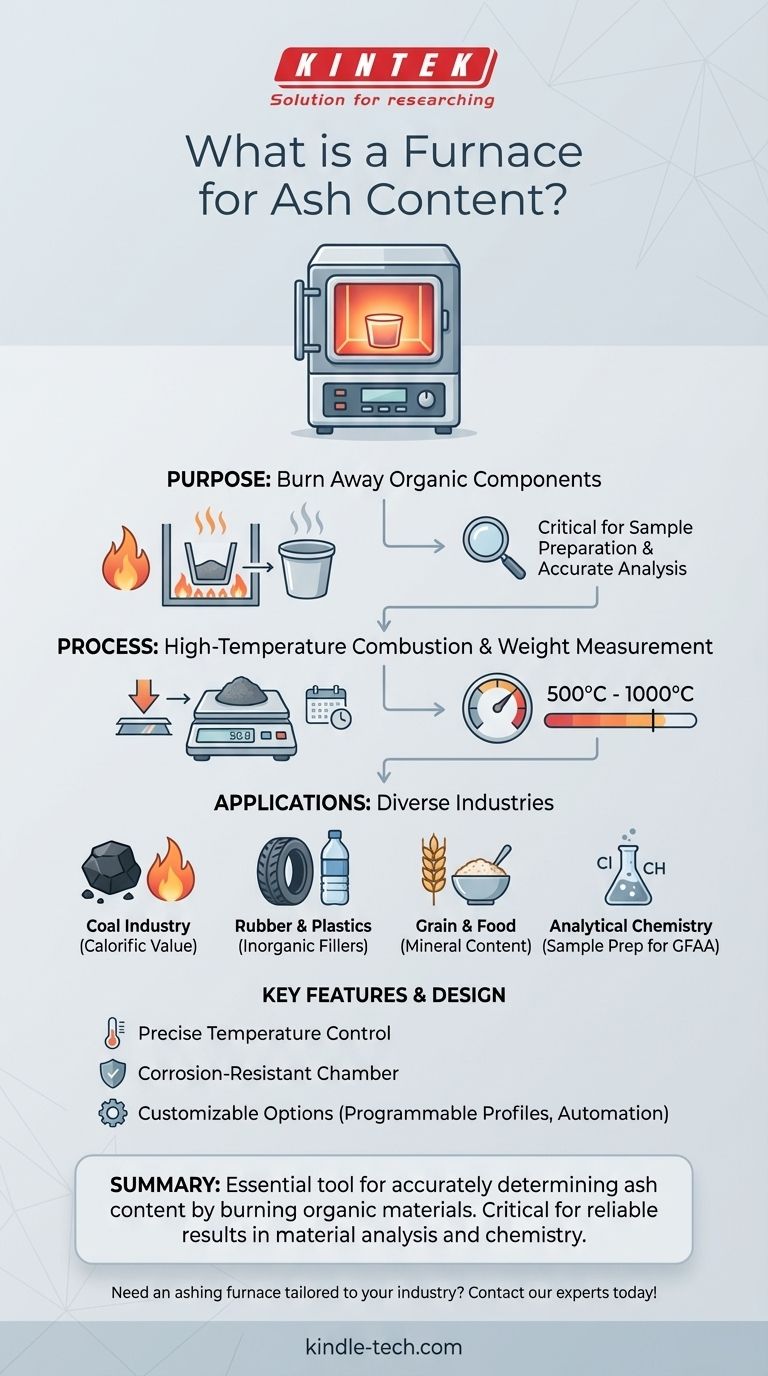

An ashing furnace is a specialized piece of equipment used to quantify the change in weight of a sample as its organic components are burned away through complete combustion. This process, known as ashing or charring, is critical for preparing samples for accurate analysis by removing interfering organic materials. Ashing furnaces are widely used in material analysis for industries such as coal, rubber, plastics, and grain. They are designed to operate at high temperatures to ensure complete combustion and are tailored to the specific requirements of the sample being tested.

Key Points Explained:

-

Purpose of an Ashing Furnace:

- An ashing furnace is primarily used to expel organic material from a sample through complete combustion. This process is essential for preparing samples for further analysis by removing matrix constituents that might interfere with the measurement of the analyte.

- It quantifies the change in weight of a sample as its components are burned away, which is crucial for determining the ash content in materials.

-

Process of Ashing:

- Combustion: The sample is subjected to high temperatures in the furnace, causing the organic material to combust and leave behind inorganic residues (ash).

- Weight Measurement: The change in weight before and after combustion is measured to determine the ash content. This is particularly important in industries where ash content is a critical quality parameter.

-

Applications:

- Coal Industry: Used to determine the ash content in coal, which affects its calorific value and combustion efficiency.

- Rubber and Plastics: Helps in analyzing the inorganic fillers and additives in rubber and plastic products.

- Grain and Food Industry: Used to measure the mineral content in grains and food products, which is important for nutritional analysis.

-

Design and Specifications:

- Ashing furnaces are designed to operate at high temperatures, typically ranging from 500°C to 1000°C, depending on the material being tested.

- They are equipped with precise temperature control systems to ensure uniform heating and complete combustion of the sample.

- The furnace chamber is often made of materials that can withstand high temperatures and resist chemical corrosion.

-

Importance in Analytical Chemistry:

- In analytical chemistry, ashing is a critical step in sample preparation, especially in techniques like graphite furnace atomic absorption (GFAA) spectroscopy.

- By removing organic matrix constituents, ashing ensures that the analyte of interest can be measured accurately without interference.

-

Variations and Customization:

- Ashing furnaces can be customized based on the specific requirements of the sample and the industry. For example, some furnaces may have additional features like programmable temperature profiles, automated sample handling, and advanced safety mechanisms.

- The choice of furnace depends on factors such as the type of material, the required temperature range, and the desired level of automation.

In summary, an ashing furnace is an essential tool for accurately determining the ash content in various materials by burning away organic components. Its applications span multiple industries, and its design is tailored to meet the specific needs of the sample being analyzed. The process of ashing is critical for ensuring accurate and reliable results in material analysis and analytical chemistry.

Summary Table:

| Key Aspect | Details |

|---|---|

| Purpose | Expels organic material through combustion for accurate sample analysis. |

| Process | High-temperature combustion and weight measurement to determine ash content. |

| Applications | Coal, rubber, plastics, and grain industries. |

| Temperature Range | 500°C to 1000°C, depending on material. |

| Design Features | Precise temperature control, corrosion-resistant materials. |

| Importance in Chemistry | Critical for sample preparation in analytical techniques like GFAA. |

| Customization | Programmable profiles, automated handling, and advanced safety options. |

Need an ashing furnace tailored to your industry? Contact our experts today to find the perfect solution!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What does 'sintered' mean and why is it important to understand? Unlock Advanced Materials & Manufacturing

- What does a lab muffle furnace do? Achieve Pure, Contamination-Free Heating for Your Lab

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement

- How long does heating take on a muffle furnace? Unlock the Key Factors for Your Lab's Efficiency

- What is the maximum temperature of a muffle furnace? Find the Right Heat for Your Application