In the laboratory, a grinder is a fundamental tool used for sample preparation. Its primary function is to take a larger, often heterogeneous sample and reduce it to a fine, uniform powder through crushing, milling, or homogenizing. This process is critical for ensuring that any small portion taken for testing is an accurate representation of the original material.

The core purpose of a laboratory grinder is not just to break things down, but to create a homogenous sample with a consistent particle size. This uniformity is the bedrock of accurate and repeatable analytical results.

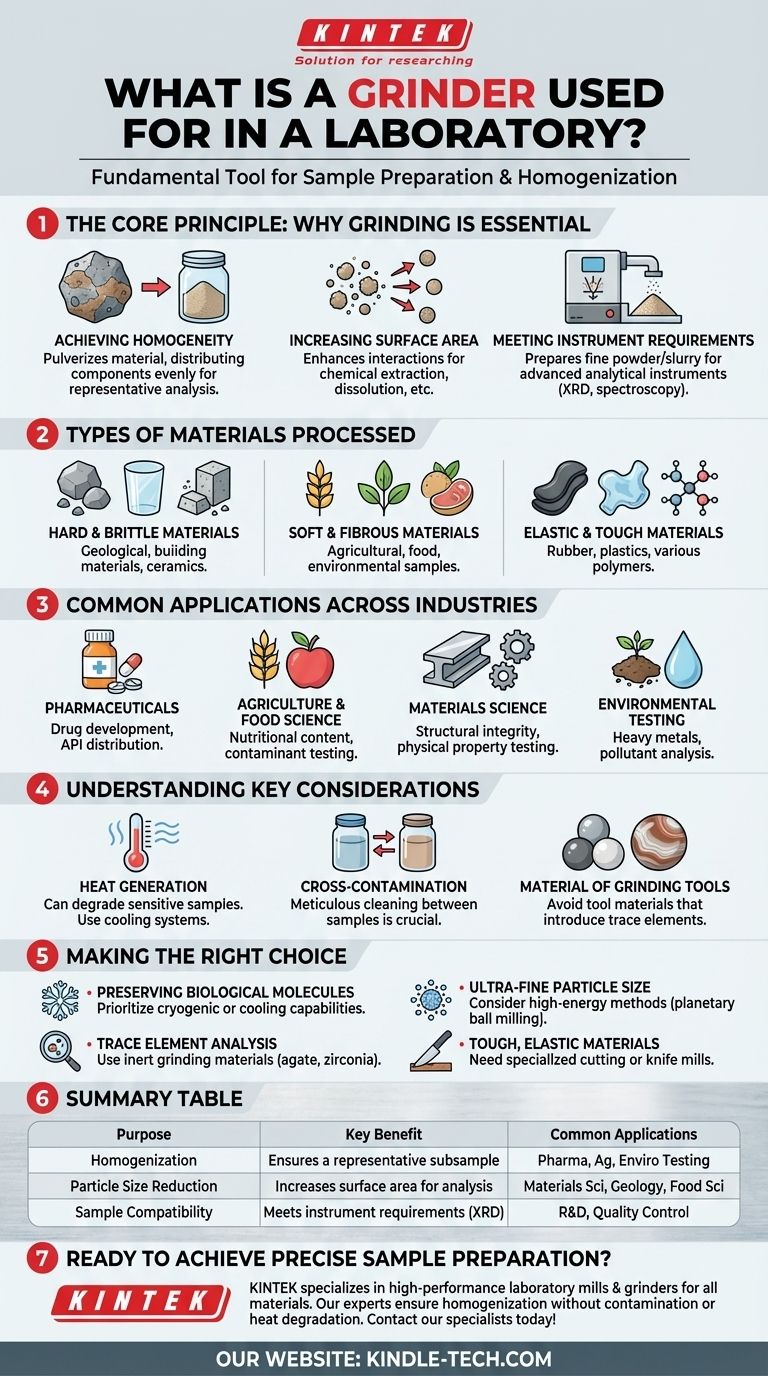

The Core Principle: Why Grinding is Essential

Effective sample preparation is the first and most critical step in nearly all material analyses. Grinding addresses several fundamental requirements for achieving reliable data.

Achieving Homogeneity

A bulk sample, like a batch of grain or a piece of rock, is rarely uniform. Grinding and mixing pulverize the material, evenly distributing all its components to ensure that a small subsample has the exact same composition as the whole.

Increasing Surface Area

Breaking a material into smaller particles dramatically increases its total surface area. This is vital for processes like chemical extraction or dissolution, as it allows solvents to interact with the sample more efficiently and completely.

Meeting Instrument Requirements

Many advanced analytical instruments require samples to be in a fine powder or liquid slurry form. A grinder prepares the material to the precise particle size specifications needed for techniques like X-ray diffraction (XRD), spectroscopy, and chromatography.

What Types of Materials Can Be Processed?

Modern laboratory mills are versatile and can be configured to handle an exceptionally wide range of materials, a key reason for their widespread use.

Hard and Brittle Materials

This category includes geological samples, building materials, and ceramics. Grinders are used to process rocks, minerals, glass, concrete, and slag for compositional analysis.

Soft and Fibrous Materials

Grinders are essential in agricultural, food, and environmental labs. They process samples like seeds, grains, plant tissue, food products, and paper to test for nutritional content, moisture, or contaminants.

Elastic and Tough Materials

Specialized mills can handle difficult materials that might otherwise deform rather than break. This includes samples like rubber, plastics, and various polymers.

Common Applications Across Industries

The need for representative samples is universal, making laboratory grinders indispensable in numerous fields.

Pharmaceuticals

In drug development, active pharmaceutical ingredients (APIs) and excipients are milled to a specific particle size. This ensures even distribution in a tablet and controls the drug's dissolution rate in the body.

Agriculture and Food Science

A food sample is homogenized to accurately test for protein, fat, fiber content, or to detect pesticides and other contaminants.

Materials Science

Engineers grind metals, alloys, and polymers to prepare them for tests that determine their structural integrity, chemical composition, and physical properties.

Environmental Testing

Soil, sludge, and waste samples are ground to a uniform powder before being tested for the presence of heavy metals and other pollutants.

Understanding the Key Considerations

While powerful, grinding is a physical process that can affect the sample. A skilled technician must account for these factors.

Heat Generation

The energy from grinding generates heat, which can degrade thermally sensitive samples like certain pharmaceuticals or biological tissues. Many advanced mills incorporate air or water cooling systems to prevent this.

Cross-Contamination

This is a primary concern. Residue from a previous sample can easily contaminate the next one, leading to false results. Meticulous cleaning between samples is non-negotiable.

Material of Grinding Tools

The material of the grinding jars and balls (e.g., steel, tungsten carbide, agate) can introduce trace elements into the sample. The choice must be made carefully to avoid contaminating the sample with the element being analyzed.

Making the Right Choice for Your Goal

The correct grinding strategy depends entirely on your sample type and what you intend to measure.

- If your primary focus is preserving biological molecules: Prioritize grinders with cryogenic or cooling capabilities to prevent heat from damaging the sample.

- If your primary focus is trace element analysis: Use grinding tools made from a material, like agate or zirconia, that will not introduce the specific metals you are measuring.

- If your primary focus is achieving an ultra-fine particle size: Consider high-energy methods like planetary ball milling for preparing samples for advanced material science.

- If your primary focus is processing tough, elastic materials: You will need a specialized cutting or knife mill that shears the material rather than crushing it.

Ultimately, proper sample grinding is the foundational step that dictates the reliability and accuracy of all subsequent laboratory analysis.

Summary Table:

| Purpose | Key Benefit | Common Applications |

|---|---|---|

| Homogenization | Ensures a representative subsample | Pharmaceuticals, Agriculture, Environmental Testing |

| Particle Size Reduction | Increases surface area for analysis | Materials Science, Geology, Food Science |

| Sample Compatibility | Meets instrument requirements (XRD, etc.) | R&D, Quality Control |

Ready to achieve precise and reliable sample preparation?

KINTEK specializes in high-performance laboratory mills and grinders designed for a vast range of materials—from hard ceramics to elastic polymers. Our experts will help you select the perfect equipment to ensure your samples are homogenized without contamination or heat degradation, guaranteeing the accuracy of your analytical results.

Contact our lab equipment specialists today to discuss your specific application and find the ideal grinder for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Single Horizontal Jar Mill

- Laboratory Micro Tissue Grinding Mill Grinder

People Also Ask

- How does a grinding mill work? A Guide to Crushing, Grinding, and Pulverizing

- What is a mortar and pestle used for in a lab? A Guide to Precision Grinding and Mixing

- What are the different types of laboratory mills? Choose the Right Grinder for Your Sample Material

- What is the laboratory apparatus used for grinding? Find the Perfect Mill for Your Sample

- How are rock samples prepared for geochemical analysis? Ensure Accurate Results with Proper Lab Protocols