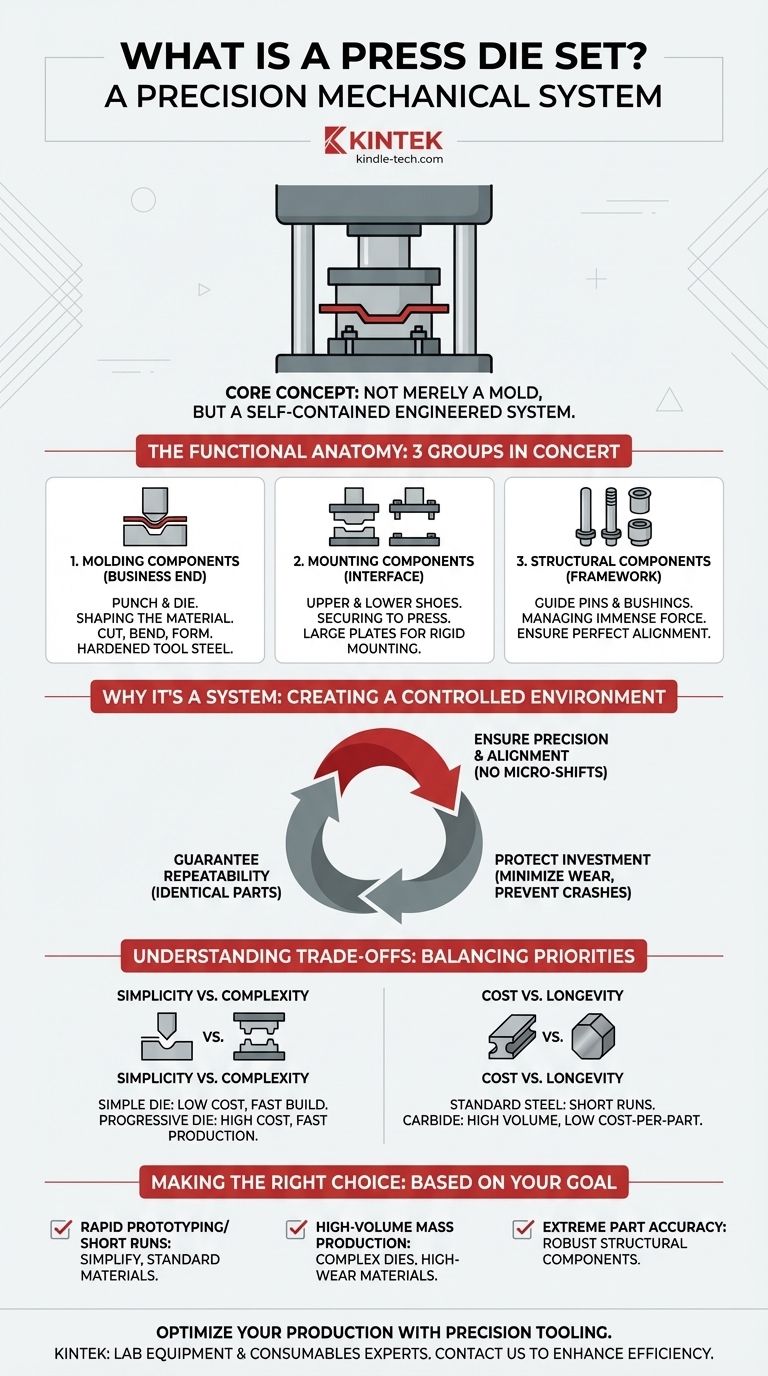

At its core, a press die set is a precision mechanical tool that holds, aligns, and actuates the components used to cut, shape, or form material in a press machine. It acts as a self-contained assembly, integrating the active tooling (like punches and dies) with a structural framework that mounts directly into the press, ensuring perfect alignment and repeatability with every machine stroke.

A press die set is not merely a mold. It is a complete engineered system designed to precisely transmit immense force from a press to a workpiece, guaranteeing the consistent and accurate production of parts at scale.

The Functional Anatomy of a Die Set

To understand a die set, you must see it as a system with three distinct functional groups working in concert. The design of each component is optimized for its specific role, from shaping the material to managing the operational forces.

The Molding Components: Shaping the Material

This is the "business end" of the tool—the parts that directly contact and alter the workpiece. In a stamping operation, this includes the punch (the male component that performs the action) and the die (the female component that defines the final shape).

These components are typically made of hardened tool steel and are responsible for the actual cutting, bending, forming, or drawing of the material. Their geometry is a direct mirror of the desired part feature.

The Mounting Components: Securing to the Press

This group of components serves as the interface between the die set and the press machine. It consists of an upper shoe (or die holder) and a lower shoe, which are large, flat plates that form the top and bottom of the assembly.

The upper shoe attaches to the moving ram of the press, while the lower shoe is bolted to the stationary bed. This secure mounting ensures the entire tool moves as a single, rigid unit with the machine.

The Structural Components: Managing Immense Force

This framework receives the tonnage from the press and ensures the molding components remain in perfect alignment under load. Key elements include guide pins and bushings.

Guide pins are hardened, precision-ground posts fixed to one die shoe that slide into corresponding bushings on the opposing shoe. This critical pairing prevents any lateral movement, maintaining the precise clearance between the punch and die throughout the entire stroke. This alignment is what guarantees part quality and prevents catastrophic tool damage.

Why a Die Set is a System, Not Just a Tool

Thinking of a die set as a simple mold misses its most important function: creating a controlled and repeatable manufacturing environment. Its design as a self-contained system is what enables modern mass production.

Ensuring Precision and Alignment

The single most important job of the die set's structure is maintaining the alignment between the upper and lower tooling. Even a microscopic shift can ruin a part, cause excessive burrs, or lead to the punch crashing into the die, destroying the tool.

The guide pins and rigid die shoes are the foundation of this precision, acting as the skeleton that holds everything in its exact place, stroke after stroke.

Guaranteeing Repeatability

Because the die set is a self-contained unit with its own internal alignment system, it produces identical parts regardless of minor variances in the press machine itself. This isolates the critical tooling from the larger machine, ensuring that the millionth part produced is an exact copy of the first.

Protecting the Investment

A die set protects both the delicate molding components and the expensive press machine. By absorbing and directing the stamping forces through its robust frame, it reduces wear and stress on the press. Most importantly, its alignment system is the primary defense against tooling crashes, which can cost tens of thousands of dollars in repairs and downtime.

Understanding the Trade-offs

The design principle of "simplicity" is a starting point, but every die set is an exercise in balancing competing priorities.

Simplicity vs. Complexity

A simple blanking die that performs one cut is relatively inexpensive and quick to build. However, a progressive die is far more complex, incorporating multiple stations to cut, bend, and form a part in a series of steps with each press stroke.

While a progressive die has a much higher initial cost and requires more maintenance, it dramatically increases production speed by completing a finished part with every cycle.

Cost vs. Longevity

The materials used for the die set components represent a significant trade-off. Using standard tool steel is cost-effective for short production runs.

For high-volume manufacturing demanding millions of cycles, investing in premium materials like carbide for the cutting components is essential. This increases the upfront cost but delivers a much lower cost-per-part over the tool's extended life.

Making the Right Choice for Your Goal

The optimal die set design depends entirely on your manufacturing objective.

- If your primary focus is rapid prototyping or short runs: Prioritize simple, single-operation dies built with standard materials to minimize initial investment and lead time.

- If your primary focus is high-volume mass production: Invest in a complex progressive or compound die made from high-wear materials to maximize throughput and ensure long-term consistency.

- If your primary focus is extreme part accuracy: Focus on the structural components, specifying oversized guide pins, high-end bushings, and a thick, rigid die shoe to guarantee stability under load.

Ultimately, viewing the die set as an integrated system is the key to unlocking efficient and precise manufacturing.

Summary Table:

| Component Group | Key Parts | Primary Function |

|---|---|---|

| Molding Components | Punch, Die | Directly cut, bend, or form the material |

| Mounting Components | Upper Shoe, Lower Shoe | Secure the die set to the press machine |

| Structural Components | Guide Pins, Bushings | Maintain alignment and manage force under load |

Ready to optimize your production with precision tooling? KINTEK specializes in lab equipment and consumables, serving laboratory needs with high-quality press die sets and support. Whether you're prototyping or scaling to mass production, our expertise ensures you get the right system for accuracy and longevity. Contact us today to discuss your project and discover how we can enhance your manufacturing efficiency!

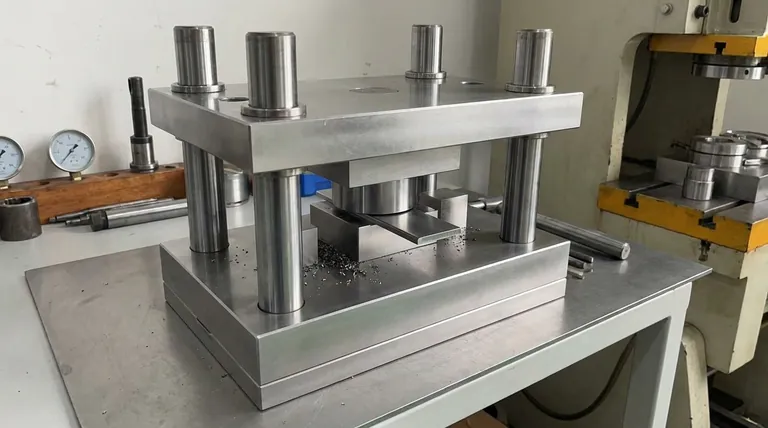

Visual Guide

Related Products

- Special Heat Press Mold for Lab Use

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Assemble Square Lab Press Mold for Laboratory Applications

- Cylindrical Press Mold with Scale for Lab

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What are the primary functions of graphite dies in sintering? Optimize Nano-AlN Sintering Efficiency

- What are the critical performance requirements for hot pressing molds? Ensure Precision in Magnesium Alloy Processing

- What are the key functions of graphite molds in PCAS of NiAl-Al2O3? Optimize Your Field-Assisted Sintering Results

- What is a custom molder? Your Partner for Custom Plastic Parts Manufacturing

- What is the difference between wet bag tooling and dry bag tooling? Choose the Right Composite Process

- What does a mould maker do? The Precision Engineer Behind Mass Production

- How to use a press mold in ceramics? A Step-by-Step Guide to Consistent, Repeatable Forms

- What is Mould filling analysis? Predict Injection Molding Defects Before Cutting the Mold