In ceramics, a press mold is a rigid or semi-rigid form used to shape clay. Clay is pressed into the mold, and once it has firmed up slightly, it is removed, retaining the shape and texture of the mold's interior. This technique creates a positive impression of the mold's negative space.

A press mold is fundamentally a tool for replication. It allows a ceramicist to consistently and efficiently reproduce a specific form, making it ideal for creating sets or complex shapes that are difficult to achieve by hand alone.

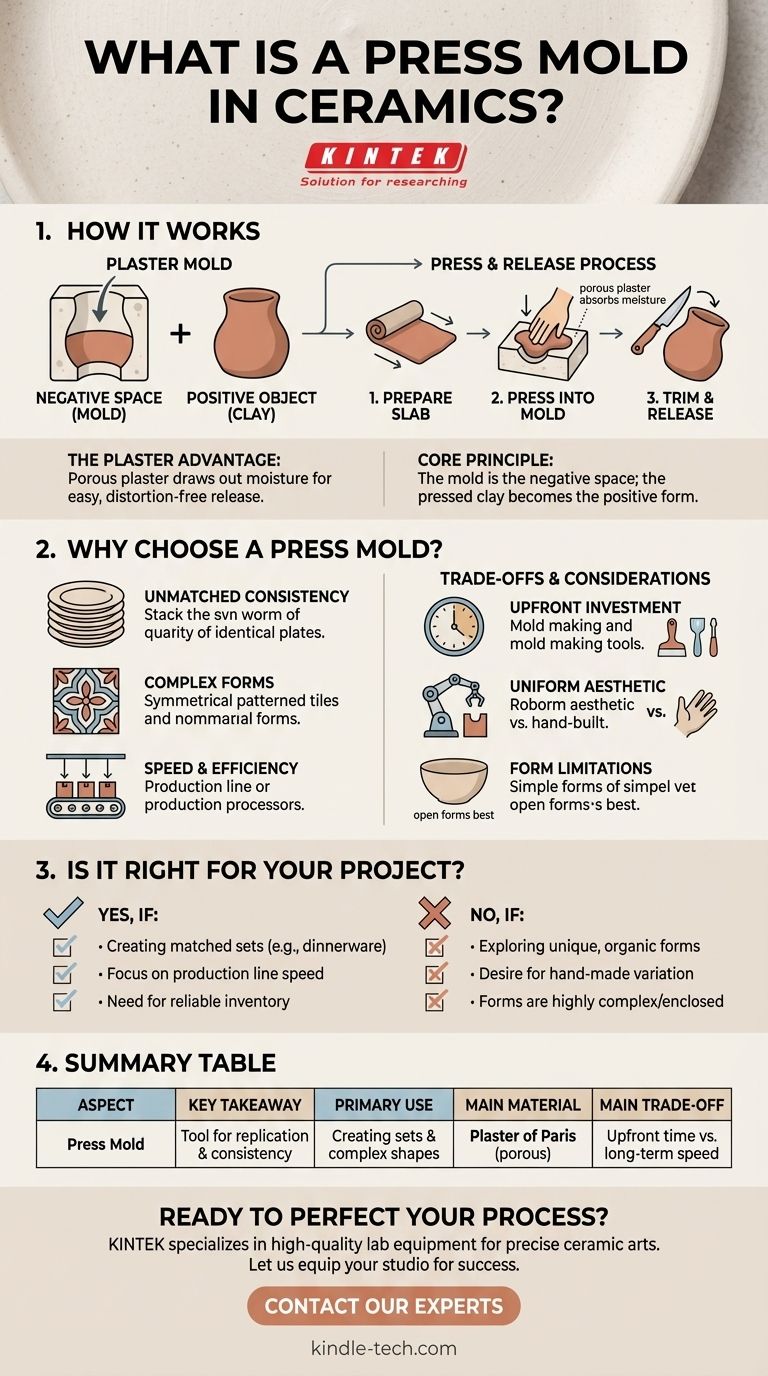

How Press Molds Fundamentally Work

To understand the value of a press mold, you must first grasp its core principles. The process is simple in theory but relies on the specific properties of the materials involved.

The Core Principle: Positive and Negative Space

A press mold is a "negative" space. It is the empty form that you want your final object to take.

When you press a slab or coils of clay into this negative space, the clay becomes the "positive" object. This is the fundamental relationship that allows for replication.

The Standard Material: Plaster

Most ceramic press molds are made from Plaster of Paris. This is not an arbitrary choice; plaster has a critical property that makes it perfect for this task.

Plaster is highly porous. It actively draws moisture out of the clay that is in contact with it. This slight drying process causes the clay to shrink away from the mold walls, making it easy to remove without distortion.

The Process: Pressing and Releasing

The workflow is straightforward. First, a clay slab is prepared to an even thickness.

This slab is then carefully pressed into the mold, ensuring it makes full contact with all surfaces to pick up any details. Excess clay is trimmed from the rim.

As the plaster absorbs water, the clay firms up and begins to release naturally from the mold, at which point it can be safely removed to dry further.

Why Choose a Press Mold?

While hand-building offers unique results for every piece, press molds are chosen for specific, practical advantages that serve both artists and production potters.

Achieving Unmatched Consistency

The primary reason to use a press mold is to achieve consistency. It is the most reliable way to make a series of identical or nearly identical pieces, such as a set of dinner plates, tiles, or matching bowls.

Creating Complex or Symmetrical Forms

Certain shapes, like a perfectly oval platter or a geometrically complex tile, are incredibly difficult and time-consuming to create by hand. A press mold allows you to produce these forms perfectly every time.

Improving Speed and Efficiency

Once the mold itself is made, the process of creating the actual clay forms is significantly faster than building each one from scratch. This makes it an essential technique for anyone looking to produce work in larger quantities.

Understanding the Trade-offs

Like any technique, press molding involves compromises. Being aware of them ensures you are choosing the right tool for your specific goal.

The Upfront Time Investment

Creating a high-quality, durable mold requires a significant initial investment of time and effort. This investment is only worthwhile if you plan to create multiple copies of the form.

A Less "Hand-Made" Aesthetic

The uniformity that is the mold's greatest strength can also be a drawback. Pieces lack the unique variations inherent in purely hand-built items, which may be a desired quality for certain artistic expressions.

Limitations on Form

Simple, one-piece press molds are best suited for open or relatively shallow forms. Creating enclosed shapes or forms with severe undercuts requires much more complex, multi-part molds that are significantly more difficult to engineer.

Is a Press Mold Right for Your Project?

Use these guidelines to decide if this technique aligns with your creative or production goals.

- If your primary focus is creating a matched set: A press mold is the ideal tool for ensuring the uniformity and consistency you need.

- If your primary focus is efficiency for a production line: This is a fundamental technique for speeding up your workflow and creating reliable inventory.

- If your primary focus is exploring unique, one-of-a-kind organic forms: You will likely find the constraints of a mold limiting; direct hand-building methods will better serve your vision.

Ultimately, a press mold is a powerful tool that translates an initial creative effort into a repeatable and reliable process.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Use | Replicating a specific form consistently and efficiently. |

| Best For | Creating sets (e.g., plates, tiles) and complex symmetrical shapes. |

| Main Material | Plaster of Paris, which draws moisture from clay for easy release. |

| Main Trade-off | Upfront time to create the mold vs. long-term production speed and uniformity. |

Ready to perfect your ceramic production process?

Whether you're a studio artist scaling up or a production potter, having the right tools is key to efficiency and consistency. At KINTEK, we specialize in the high-quality lab equipment and consumables that support precise ceramic arts, from material preparation to final finishing.

Let us help you equip your studio for success. Contact our experts today to discuss how our solutions can streamline your workflow and bring your ceramic visions to life with reliability and precision.

Visual Guide

Related Products

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- No Demolding Lab Infrared Press Mold for Laboratory Applications

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

People Also Ask

- What is the necessity of using a laboratory hydraulic pellet press for preparing solid catalysts? Maximize Catalyst Performance

- What is vulcanizing used for? Unlock the Strength and Durability of Rubber

- How to make compound rubber? Master the Sequence to Prevent Scorch and Ensure Quality

- What are the ingredients used in rubber compounding? A Guide to the Essential Formula

- What does vulcanizing a tire do? Achieve a Permanent, Structural Tire Repair