In a modern furnace, the component commonly referred to as a "vacuum switch" is more accurately called a pressure switch. It is a critical safety device that verifies your furnace's exhaust system is working correctly before allowing the main burners to ignite. It ensures that dangerous combustion byproducts, like carbon monoxide, are being safely vented out of your home.

A furnace pressure switch acts as a safety gatekeeper. Its sole purpose is to confirm that the draft inducer motor is creating the necessary negative pressure (a vacuum) to pull exhaust fumes through the vent pipe, preventing them from entering your living space.

The Purpose of a Furnace Pressure Switch

A Critical Safety Mandate

The primary role of the pressure switch is safety. When a furnace burns fuel, it creates harmful gases. The pressure switch ensures these gases are being actively and safely exhausted from the building.

If the venting system is blocked or the draft motor fails, the switch detects the lack of proper airflow. It will then prevent the furnace from igniting, avoiding a dangerous buildup of toxic gases inside the furnace and your home.

The "Vacuum" in Vacuum Switch

The term "vacuum switch" is used because the component is designed to detect negative pressure. When the furnace's draft inducer motor turns on, it creates suction—a slight vacuum—in the vent pipe. The pressure switch measures this suction.

If the suction reaches the correct, pre-set level, the switch closes an electrical circuit, signaling to the furnace control board that it is safe to proceed with the ignition sequence.

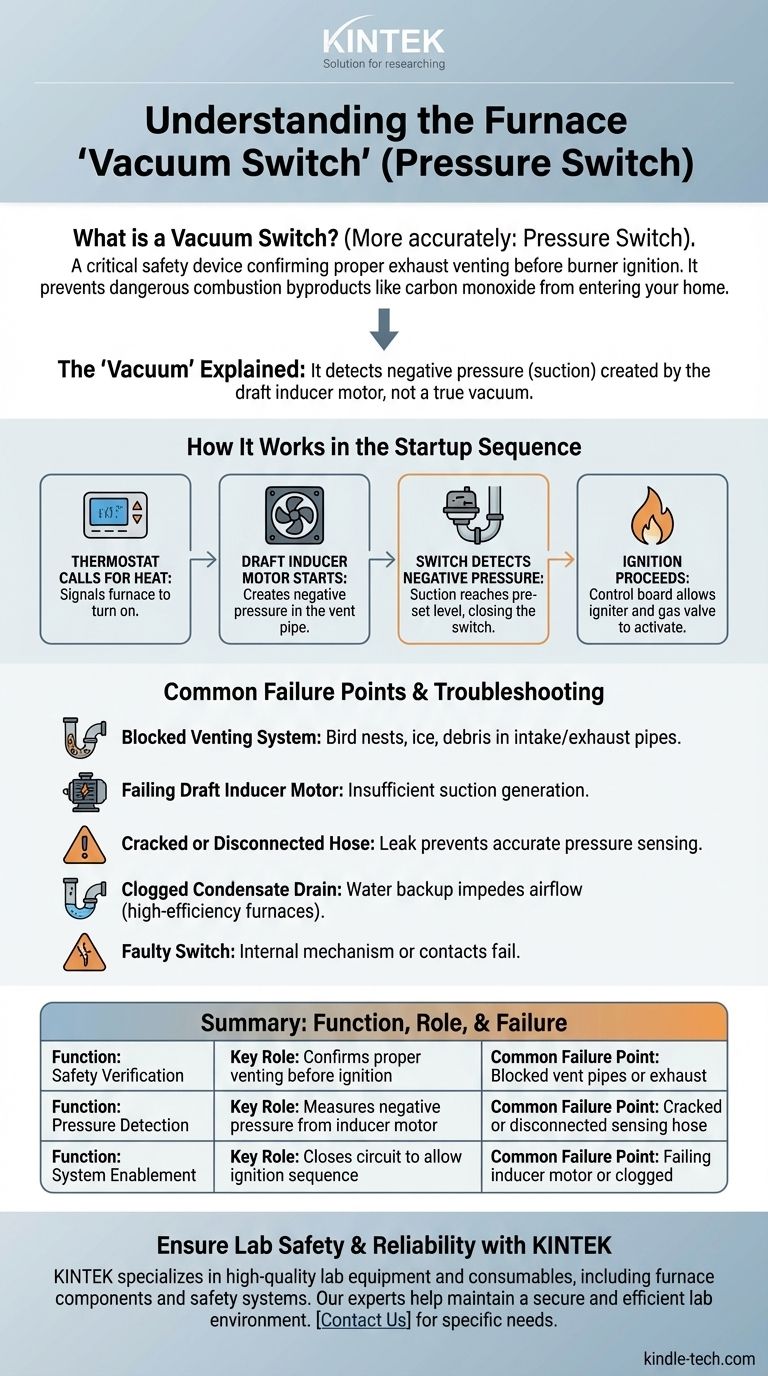

How the Switch Works in the Startup Sequence

The pressure switch operates in a precise order every time your thermostat calls for heat. It is one of the first checks in the furnace's ignition sequence.

Step 1: The Call for Heat

The sequence begins when your thermostat signals the furnace to turn on.

Step 2: The Draft Inducer Motor Starts

Before any gas is released or ignited, the furnace control board activates the draft inducer motor. This is a small fan that begins pulling air through the heat exchanger and pushing it out the exhaust vent.

Step 3: The Switch Detects Negative Pressure

As the motor runs, it creates the necessary negative pressure. This suction is transmitted to the pressure switch through a small rubber or silicone hose.

Step 4: The Switch Closes and Ignition Proceeds

Once the switch detects that the required negative pressure has been met, it closes, completing a low-voltage electrical circuit. This tells the control board that the venting system is clear and operational. Only then will the control board proceed to the next steps: heating the igniter and opening the gas valve.

Common Failure Points and What They Mean

If the pressure switch fails to close, the furnace will not ignite, and the system will shut down. This is often indicated by a blinking error code on the furnace control board. The failure is not always the switch itself, but often an issue elsewhere in the system.

Blockages in the Venting System

This is the most common cause. A bird's nest, ice, snow, or other debris can obstruct the PVC intake or exhaust pipes outside your home. The blockage prevents the inducer motor from creating the required suction, so the switch rightfully remains open.

A Failing Draft Inducer Motor

If the inducer motor is failing, it may not spin fast enough to generate the necessary negative pressure. The pressure switch will correctly detect this insufficient draft and prevent ignition.

A Cracked or Disconnected Hose

The small hose connecting the draft motor to the pressure switch can become brittle, cracked, or disconnected over time. A leak in this hose will prevent the switch from sensing the true vacuum level, causing a fault.

A Clogged Condensate Drain

In high-efficiency condensing furnaces, a clogged condensate drain line can cause water to back up into the inducer motor housing. This blockage can impede airflow and prevent the pressure switch from closing.

A Faulty Switch

While less common, the switch itself can fail. The internal diaphragm can get stuck or the electrical contacts can wear out, causing it to fail even when the proper vacuum is present.

Making the Right Choice for Your Goal

Understanding the pressure switch's function helps you diagnose furnace issues more effectively.

-

If your primary focus is understanding your furnace: Recognize that the pressure switch is a simple but non-negotiable safety component that confirms proper venting before every single heating cycle.

-

If your primary focus is troubleshooting a no-heat situation: The pressure switch is a key checkpoint. Before assuming the switch is bad, always inspect for blocked vent pipes, a clogged condensate drain, and a cracked or loose sensing hose first, as these are far more common root causes.

This small, simple switch serves as a vital guardian of your furnace's safe operation.

Summary Table:

| Function | Key Role | Common Failure Point |

|---|---|---|

| Safety Verification | Confirms proper venting before ignition | Blocked vent pipes or exhaust |

| Pressure Detection | Measures negative pressure (vacuum) from the draft inducer motor | Cracked or disconnected sensing hose |

| System Enablement | Closes an electrical circuit to allow the ignition sequence to proceed | Failing draft inducer motor or clogged condensate drain |

Ensure your lab's heating equipment operates with maximum safety and reliability. KINTEK specializes in high-quality lab equipment and consumables, including furnace components and safety systems. Our experts can help you select the right parts to maintain a secure and efficient laboratory environment. Contact us today to discuss your specific laboratory needs and how we can support your operations.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the thickness of quartz tubing? Choose the Right Wall Thickness for Your Application

- What are the fundamental differences between low-cost and high-end industrial rotary vane vacuum pumps? | KINTEK

- Why is high-purity alumina preferred over mullite for CNT synthesis? Ensure Structural Stability at 1420°C

- What are the main disadvantages associated with Rotary Vane Pumps? Avoid Contamination & High Maintenance Costs

- Why is the use of high-grade corrosion-resistant lab equipment essential? Ensure Safety & Biomass Data Integrity

- Why is a high-speed magnetic stirrer utilized for MFC? Enhance Deacetylation, Bleaching, and Hydrolysis Efficiency

- How does a Type K thermocouple ensure data quality in supercritical water process control? Master Precision Monitoring

- What factors should be considered when choosing a vacuum pump for laboratory use? Match Your Lab's Needs