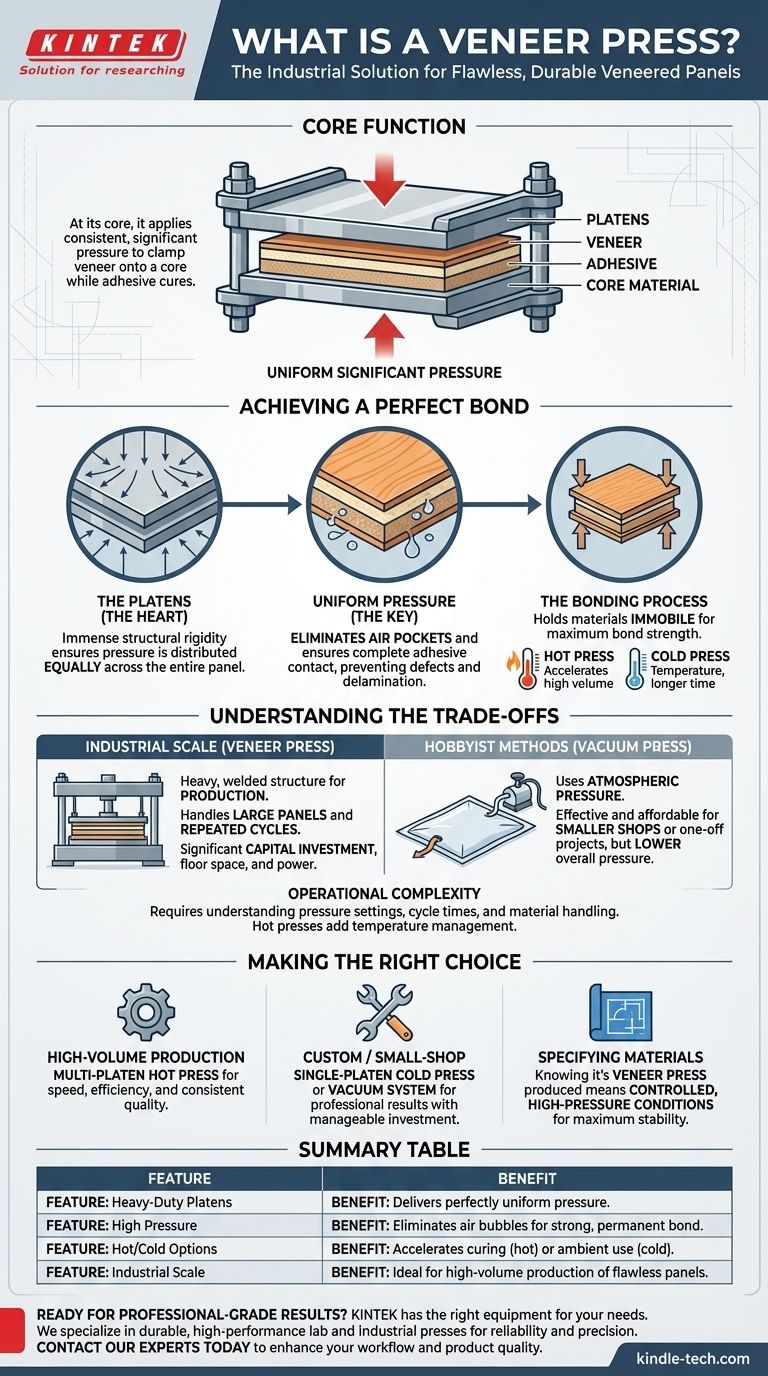

At its core, a veneer press is a heavy-duty machine designed to apply consistent and significant pressure across the entire surface of a panel. It utilizes one or more large, flat plates, called platens, to clamp a thin layer of wood veneer onto a core material while the adhesive cures, ensuring a strong and permanent bond.

The critical function of a veneer press isn't just applying force; it's about achieving perfectly uniform pressure. This control is essential for eliminating air pockets and ensuring complete adhesive contact, which is the only way to create a professional, durable, and delamination-free veneered panel.

How a Veneer Press Achieves a Perfect Bond

The effectiveness of a veneer press lies in its simple but powerful mechanical design. Its entire structure is built to deliver controlled pressure evenly over a large area, solving the fundamental challenge of veneering.

The Role of the Platens

The platens are the heart of the press. These are the thick, flat steel plates that make direct contact with the panel assembly (often through a protective layer).

Their immense structural rigidity ensures that pressure is distributed equally, from the center of the panel all the way to the edges.

The Importance of Uniform Pressure

Without uniform pressure, small air bubbles and gaps can get trapped between the veneer and the core material.

These imperfections create weak spots in the bond, leading to visible defects or outright failure (delamination) over time as humidity and temperature change. The press systematically forces out this trapped air.

The Bonding Process

The press holds the veneer and substrate perfectly immobile while the glue cures. This static, high-pressure environment is the ideal condition for modern adhesives to achieve their maximum bond strength.

Some presses, known as hot presses, have heated platens to dramatically accelerate the glue's curing time, making them ideal for high-volume production. Cold presses operate at ambient temperature and require longer clamping times.

Understanding the Trade-offs

While veneer presses are the gold standard for lamination, their industrial nature comes with specific considerations. They are not the only method for applying veneer, and their utility depends entirely on the scale of the operation.

Industrial Scale vs. Hobbyist Methods

The heavy, welded structure of a veneer press is built for the rigors of a production environment, handling large panels and repeated cycles.

For smaller shops or one-off projects, a vacuum press (or vacuum bag) serves a similar function. It uses atmospheric pressure to clamp the veneer, offering an effective and much more affordable alternative, albeit with lower overall pressure.

Cost and Space

Veneer presses are significant capital investments that demand considerable floor space and power. Their cost and footprint place them firmly in the category of industrial machinery.

Operational Complexity

While straightforward in principle, operating a large press requires an understanding of pressure settings, cycle times, and material handling. Hot presses add the complexity of managing temperature for different adhesives and materials.

Making the Right Choice for Your Goal

Understanding the function of a veneer press helps you specify materials correctly or choose the right equipment for your own fabrication needs.

- If your primary focus is high-volume production: A multi-platen hot press is the definitive tool for achieving speed, efficiency, and consistent quality.

- If your primary focus is custom or small-shop work: A single-platen cold press or a vacuum press system offers professional results with a more manageable investment.

- If you are designing or specifying materials: Knowing that a panel was made in a veneer press tells you it was produced under controlled, high-pressure conditions for maximum stability and bond integrity.

Ultimately, the veneer press is the industrial tool that transforms a raw substrate and a delicate veneer into a single, stable, and flawless panel.

Summary Table:

| Feature | Benefit |

|---|---|

| Heavy-Duty Platens | Delivers perfectly uniform pressure across the entire panel surface |

| High Pressure | Eliminates air pockets for a strong, permanent bond |

| Hot/Cold Options | Accelerates glue curing (hot) or operates at ambient temperature (cold) |

| Industrial Scale | Ideal for high-volume production of flawless, stable panels |

Ready to achieve professional-grade veneering results?

Whether you're scaling up production or outfitting a custom shop, KINTEK has the right equipment for your needs. We specialize in durable, high-performance lab and industrial equipment, including presses designed for reliability and precision.

Contact our experts today to discuss how our solutions can enhance your workflow and product quality.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts