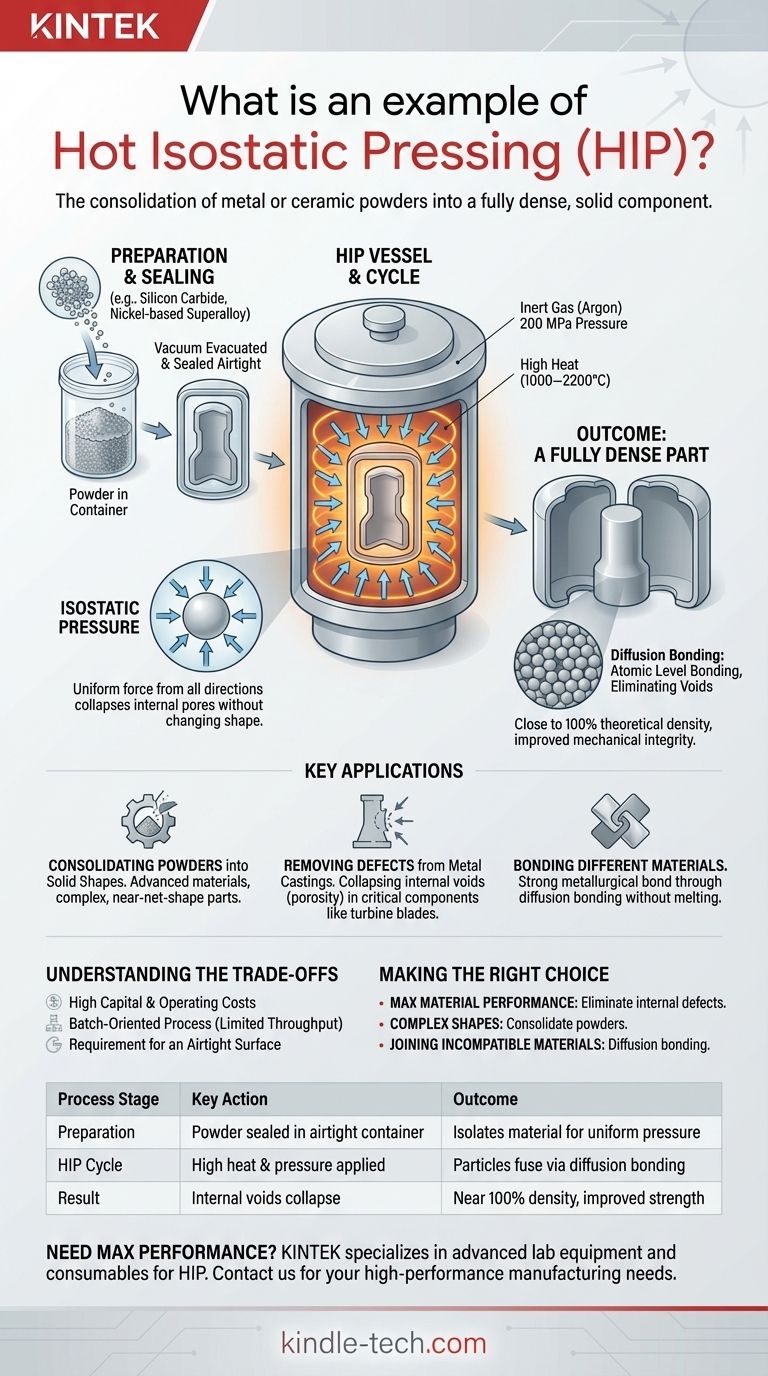

A classic example of hot isostatic pressing (HIP) is the consolidation of metal or ceramic powders into a fully dense, solid component. In this process, a powder like silicon carbide or a nickel-based superalloy is sealed under vacuum inside a metal or glass container. This container is then placed inside a HIP vessel where immense, uniform pressure (up to 200 MPa) and high heat are applied, causing the individual powder particles to fuse together and eliminating all internal voids.

The core purpose of hot isostatic pressing is not to reshape a component, but to fundamentally perfect its internal structure. It leverages uniform, high-pressure gas at elevated temperatures to eliminate internal porosity, creating materials with superior density and mechanical integrity.

How the HIP Process Achieves Densification

Hot isostatic pressing is a precise manufacturing process that combines three key elements—high temperature, high pressure, and an inert atmosphere—to achieve results that other methods cannot.

### The Preparation and Sealing Stage

For powdered materials, the process begins by placing the powder into a container, often made of metal, that is shaped to the desired final component. This container is then evacuated to create a vacuum and sealed airtight.

This sealing is critical because it isolates the material from the pressurizing gas and allows the external pressure to act uniformly on the powder within.

### The HIP Cycle: Pressure and Temperature

The sealed container is loaded into a cylindrical heating chamber. The chamber is filled with an inert gas, typically argon, which will not react with the material.

As the furnace heats the component to a specific temperature (often 1000–2200°C), the gas pressure is simultaneously increased. This combination of heat and pressure is maintained for a set period.

### The Role of Isostatic Pressure

The term "isostatic" is key to understanding the process. It means that the high-pressure gas exerts force equally on the component from all directions.

Because the pressure is perfectly uniform, it collapses internal pores and voids without changing the component's overall macroscopic shape.

### The Outcome: A Fully Dense Part

The immense pressure and high temperature force the individual powder particles or internal surfaces of a casting to bond together on an atomic level. This process, known as diffusion bonding, eliminates the microscopic gaps, resulting in a part that is close to 100% of its theoretical maximum density.

Key Applications of Hot Isostatic Pressing

The unique capabilities of HIP make it essential for manufacturing high-performance components where internal flaws would be catastrophic.

### Consolidating Powders into Solid Shapes

HIP is a primary method for creating fully dense parts from advanced metal, ceramic, or composite powders. This is especially useful for materials that are difficult to cast or machine, allowing for the creation of complex, near-net-shape components.

### Removing Defects from Metal Castings

Many critical cast components, such as turbine blades for jet engines or medical implants, can have microscopic internal voids (porosity) left over from the casting process. HIP subjects these parts to its cycle, collapsing the voids and significantly improving the material's fatigue life and strength.

### Bonding Different Materials

HIP can be used to create a powerful metallurgical bond between dissimilar materials without melting them. By placing two different materials in intimate contact within the HIP chamber, the heat and pressure cause atoms to diffuse across the boundary, creating a seamless, solid-state joint that is often stronger than the parent materials.

Understanding the Trade-offs

While incredibly effective, HIP is a specialized process with specific considerations that make it unsuitable for all applications.

### High Capital and Operating Costs

The equipment required to safely contain extreme temperatures and pressures is complex and expensive. The process is also energy-intensive, contributing to a higher per-part cost compared to conventional manufacturing methods.

### A Batch-Oriented Process

HIP is not a continuous process. Parts must be loaded into the chamber, run through a specific time-temperature-pressure cycle, and then cooled before being removed. This batch nature limits throughput compared to other methods.

### Requirement for an Airtight Surface

For the process to work on components with existing porosity (like castings), the pores must be internal and not connected to the surface. If pores are open to the surface, the pressurizing gas will simply enter the voids instead of collapsing them.

Making the Right Choice for Your Goal

Deciding to use HIP depends entirely on the performance requirements of your component.

- If your primary focus is maximum material performance: Use HIP to eliminate internal defects in critical components like aerospace castings or medical implants, achieving mechanical properties not possible otherwise.

- If your primary focus is creating complex shapes from advanced materials: Use HIP to consolidate difficult-to-machine metal or ceramic powders into a solid, near-net-shape part.

- If your primary focus is joining incompatible materials: Use HIP for diffusion bonding to create bimetallic components without the defects of traditional welding or brazing.

Ultimately, hot isostatic pressing is a powerful tool for engineering materials at a microscopic level to achieve exceptional macroscopic performance.

Summary Table:

| Process Stage | Key Action | Outcome |

|---|---|---|

| Preparation | Powder sealed in airtight container | Isolates material for uniform pressure |

| HIP Cycle | High heat (1000–2200°C) & pressure (up to 200 MPa) applied | Particles fuse via diffusion bonding |

| Result | Internal voids collapse | Near 100% density, improved strength & fatigue life |

Need to achieve maximum material performance for your critical components? KINTEK specializes in advanced lab equipment and consumables, including solutions for materials processing like hot isostatic pressing. Whether you're consolidating advanced powders, eliminating defects in aerospace castings, or diffusion bonding dissimilar materials, our expertise can help you perfect your internal structures and achieve superior mechanical properties. Contact our experts today to discuss how we can support your laboratory's high-performance manufacturing needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the pressure of isostatic fluid? Achieve Perfectly Uniform Density and Complex Shapes

- What is the dry bag process of isostatic pressing? Ideal for High-Volume Production of Simple Shapes

- What is the dry bag process? A Guide to High-Speed Isostatic Pressing

- What is isostatic pressing method for ceramics? Achieve Uniform Density for Complex Parts

- What is isostatic pressing of polymers? Achieve Superior Uniform Density for High-Performance Parts

- What are the advantages of the isostatic pressing process? Achieve High Density and Complex Geometries

- What products are made by isostatic pressing? Achieve Flawless, High-Performance Components

- Purpose of CIP in c-LLZO ceramic pellets? Achieve >90% Density & Superior Uniformity with Cold Isostatic Pressing