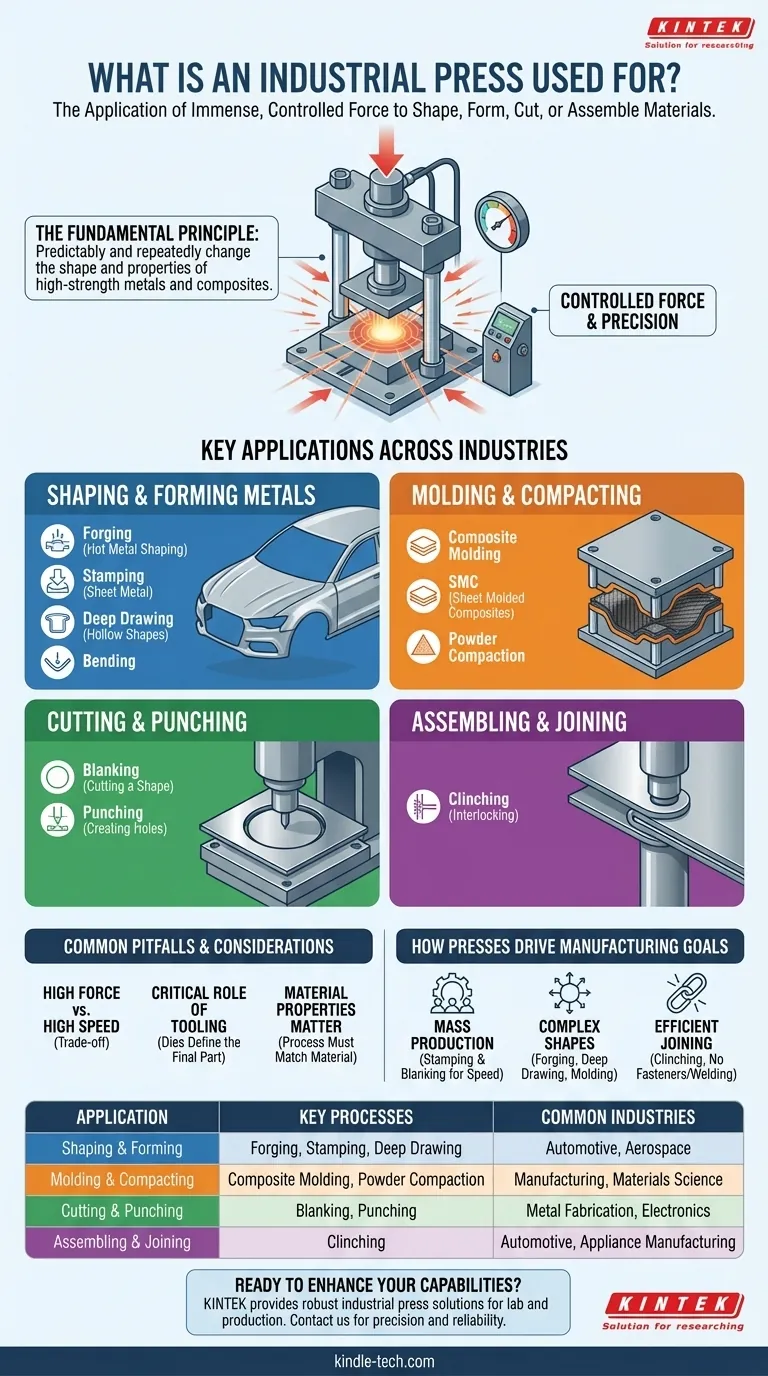

At its core, an industrial press is a machine used to shape, form, cut, or assemble materials through the application of immense, controlled force. These machines are the workhorses of modern manufacturing, used for everything from stamping car doors and forging aerospace components to molding composite materials and compacting powders.

The specific task an industrial press performs is less important than its fundamental capability: delivering a massive and highly controllable force to a workpiece. This single function is what makes it an indispensable tool across dozens of different industries and applications.

The Fundamental Principle: Controlled Force

An industrial press's primary job is not just to crush things, but to deliver a precise amount of force to a specific area. This allows manufacturers to predictably and repeatedly change the shape and properties of a material.

The machine's power enables it to work with high-strength metals and composites that would be impossible to shape by other means. The control it offers ensures every part meets exact specifications, a critical requirement in sectors like automotive and aerospace.

Key Applications Across Industries

While the principle is simple, its applications are incredibly diverse. Industrial presses are used for a wide range of forming, cutting, and assembly operations.

Shaping and Forming Metals

This is the most common category of use. A press, equipped with specialized dies, forces metal into a new shape without removing any material.

Key processes include forging (shaping hot metal), stamping (forming sheet metal like car body panels), deep drawing (creating hollow, cup-like shapes), and bending.

Molding and Compacting

Presses are essential for creating parts from non-metallic materials or powders. This involves compressing the material within a mold until it solidifies into the desired shape.

This is used for carbon fiber molding, creating sheet molded composites (SMC), and compacting powders into solid forms.

Cutting and Punching

Using a sharp die, a press can perform high-force cutting operations on sheet metal with incredible speed and precision.

The two main operations are blanking (cutting a desired shape out of a larger sheet) and punching (creating holes within a workpiece).

Assembling and Joining

Force can also be used to join parts together permanently.

A common press application is clinching, a process that locks two pieces of sheet metal together by forming a small, interlocking extrusion, eliminating the need for fasteners or welding.

Common Pitfalls and Considerations

While powerful, a press is only one part of a larger manufacturing system. Success depends on understanding the entire process.

High Force vs. High Speed

There is often a trade-off between the maximum force a press can deliver and the speed at which it can cycle. Presses for deep drawing or forging might be slower but deliver enormous tonnage, while stamping presses for smaller parts prioritize high speed for mass production.

The Critical Role of Tooling

The press provides the force, but the tooling (the dies) defines the final part. The design, engineering, and cost of this tooling is often the most complex and expensive part of the entire setup. Poor tooling will produce bad parts, no matter how good the press is.

Material Properties Matter

Different materials react to pressure in different ways. A process and die set designed for mild steel will not work for high-strength aluminum or carbon fiber. A deep understanding of material science is critical to successful press operations.

How Presses Drive Manufacturing Goals

The best process depends entirely on the desired outcome for your part or product.

- If your primary focus is mass-producing identical sheet metal parts: Stamping and blanking operations offer unmatched speed and repeatability.

- If your primary focus is creating strong, complex, three-dimensional shapes: Forging, deep drawing, or composite molding are the ideal applications.

- If your primary focus is efficiently joining components without welding: Clinching provides a fast, clean, and reliable assembly method.

Ultimately, understanding the core function of an industrial press—the precise application of force—is the key to leveraging its vast manufacturing potential.

Summary Table:

| Application | Key Processes | Common Industries |

|---|---|---|

| Shaping & Forming | Forging, Stamping, Deep Drawing | Automotive, Aerospace |

| Molding & Compacting | Composite Molding, Powder Compaction | Manufacturing, Materials Science |

| Cutting & Punching | Blanking, Punching | Metal Fabrication, Electronics |

| Assembling & Joining | Clinching | Automotive, Appliance Manufacturing |

Ready to enhance your manufacturing capabilities? KINTEK specializes in providing robust industrial press solutions and expert support for your lab and production needs. Whether you're forging critical components or molding advanced composites, our equipment delivers the precision and reliability you require. Contact our team today to discuss how we can support your specific application and drive efficiency in your operations.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics