In the simplest terms, bio-oil is a liquid fuel produced by rapidly heating organic matter, such as wood or agricultural waste, in an environment without oxygen. This process, known as pyrolysis, effectively "pressure-cooks" the biomass, breaking it down into vapors which are then cooled and condensed into a dark, thick liquid often called bio-crude.

Bio-oil is not a direct "green" replacement for petroleum. It is a renewable but chemically distinct intermediate product—a form of synthetic tar—that requires significant upgrading before it can be used like conventional fuels.

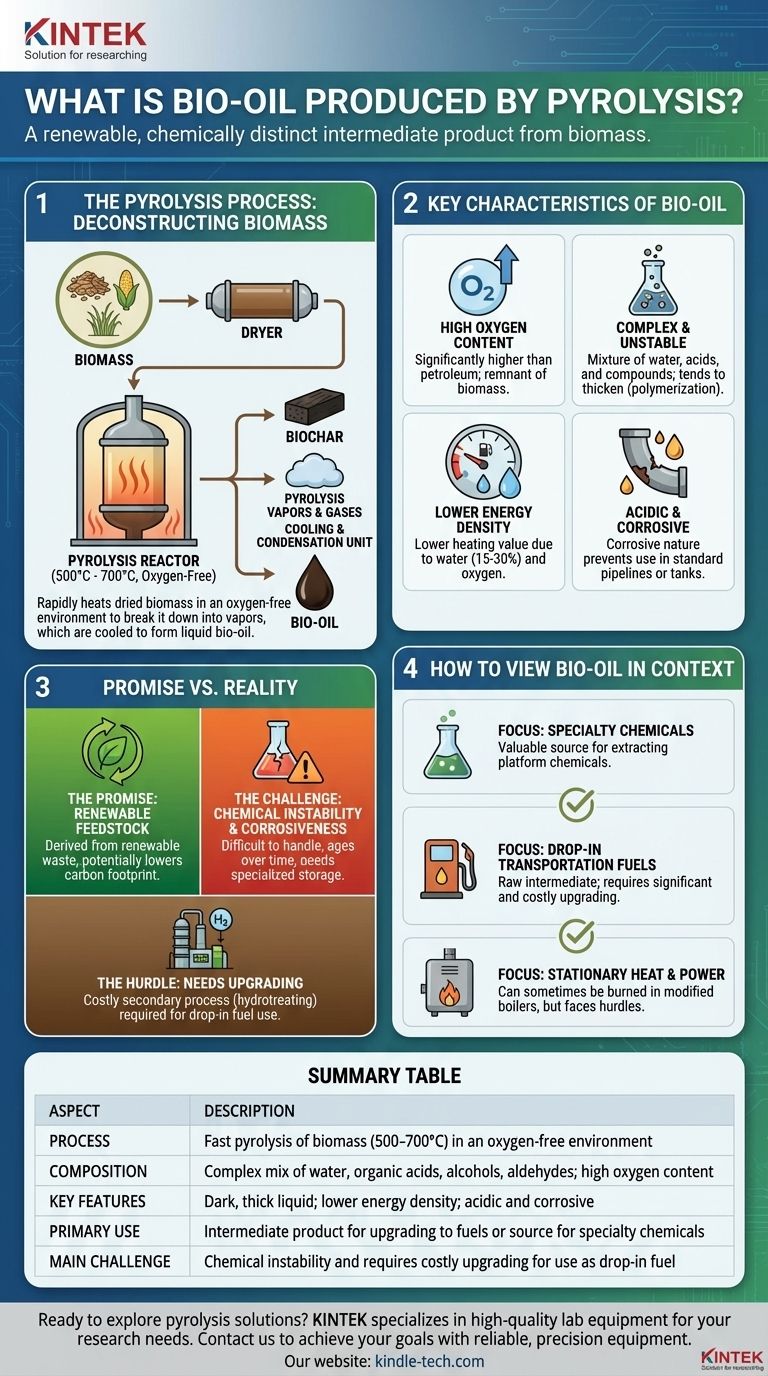

The Pyrolysis Process: Deconstructing Biomass

To understand what bio-oil is, we must first understand how it is made. The process hinges on thermal decomposition in a controlled environment.

The Raw Material: Biomass

The starting point is biomass. This is a broad term for any organic material, including wood chips, corn stover, switchgrass, or other agricultural and forestry residues. For the process to be efficient, this biomass must first be dried.

The High-Heat, No-Oxygen Reactor

The dried biomass is fed into a reactor and heated rapidly to temperatures between 500°C and 700°C (around 900°F).

Crucially, this occurs in an oxygen-free atmosphere. The absence of oxygen prevents the biomass from burning (combustion) and instead forces it to break down chemically.

From Vapor to Liquid

This intense heat breaks the solid biomass into three primary products: pyrolysis vapors, non-condensable gases, and a solid carbon-rich byproduct called biochar.

The biochar is separated out, and the hot vapors are then rapidly cooled. This cooling causes them to condense into the liquid bio-oil.

Key Characteristics of Bio-Oil

Bio-oil is fundamentally different from the petroleum crude oil it seeks to replace. Its unique chemical makeup defines both its potential and its challenges.

High Oxygen Content

Unlike petroleum, which is composed almost entirely of hydrocarbons (hydrogen and carbon), bio-oil has a very high oxygen content.

This oxygen is a remnant of the original biomass structure. It is the single most important factor that distinguishes bio-oil from fossil fuels.

A Complex and Unstable Mixture

The high oxygen content makes bio-oil a complex mixture of water, organic acids, alcohols, aldehydes, and hundreds of other compounds. It is not a uniform product.

This chemical profile makes raw bio-oil acidic, corrosive, and chemically unstable. It can thicken and even solidify over time, a process called polymerization.

Lower Energy Density

Bio-oil also contains a significant amount of water (typically 15-30%), which is created during the pyrolysis process.

This, combined with its high oxygen content, gives it a lower heating value or energy density compared to petroleum fuels. You need more bio-oil to generate the same amount of energy.

Understanding the Trade-offs: Promise vs. Reality

Bio-oil presents a classic engineering trade-off between its renewable origin and its practical limitations.

The Promise: A Renewable Feedstock

The primary advantage is clear: bio-oil is derived from renewable, often waste, biomass. This offers a path to reduce dependence on finite fossil fuels and potentially lower the carbon footprint of fuels and chemicals.

The Challenge: Chemical Instability and Corrosiveness

The reality is that raw bio-oil is a difficult substance to work with. Its acidic nature means it cannot be transported in conventional pipelines or stored in standard steel tanks without causing corrosion. Its tendency to age and thicken complicates long-term storage.

The Hurdle: The Need for Upgrading

Because of these issues, bio-oil cannot be used as a "drop-in" fuel in modern engines or refineries. It must first undergo a significant and costly secondary process called upgrading.

Upgrading typically involves reacting the bio-oil with hydrogen at high pressure (hydrotreating) to remove oxygen and stabilize the molecules. This creates a more hydrocarbon-like, refinery-ready product.

How to View Bio-Oil in Context

Based on its properties, the value of bio-oil depends entirely on the intended application.

- If your primary focus is producing specialty chemicals: Bio-oil can be a valuable source for extracting specific platform chemicals (like acetic acid or phenols), bypassing the need for fuel upgrading.

- If your primary focus is creating drop-in transportation fuels: View bio-oil as a raw, intermediate feedstock that requires significant and costly upgrading before it can be blended with gasoline or diesel.

- If your primary focus is stationary heat and power: Raw bio-oil can sometimes be burned directly in modified industrial boilers or furnaces, but its corrosiveness and lower energy value remain major technical hurdles.

Ultimately, understanding bio-oil means seeing it not as a finished product, but as a renewable starting point in a complex chemical supply chain.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Fast pyrolysis of biomass (500-700°C) in an oxygen-free environment |

| Composition | Complex mix of water, organic acids, alcohols, aldehydes; high oxygen content |

| Key Features | Dark, thick liquid; lower energy density than petroleum; acidic and corrosive |

| Primary Use | Intermediate product for upgrading to fuels or source for specialty chemicals |

| Main Challenge | Chemical instability and requires costly upgrading for use as drop-in fuel |

Ready to explore pyrolysis solutions for your laboratory or research needs? KINTEK specializes in high-quality lab equipment and consumables, including pyrolysis systems and related technologies. Whether you're developing bio-oil applications, analyzing biomass, or advancing renewable energy research, our expertise and products can support your work. Contact us today to discuss how we can help you achieve your research and production goals with reliable, precision equipment tailored to your laboratory requirements.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Customizable Fuel Cell Stack Components for Diverse Applications

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- High Purity Zinc Foil for Battery Lab Applications

People Also Ask

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste